Jun . 06, 2025 20:06 Back to list

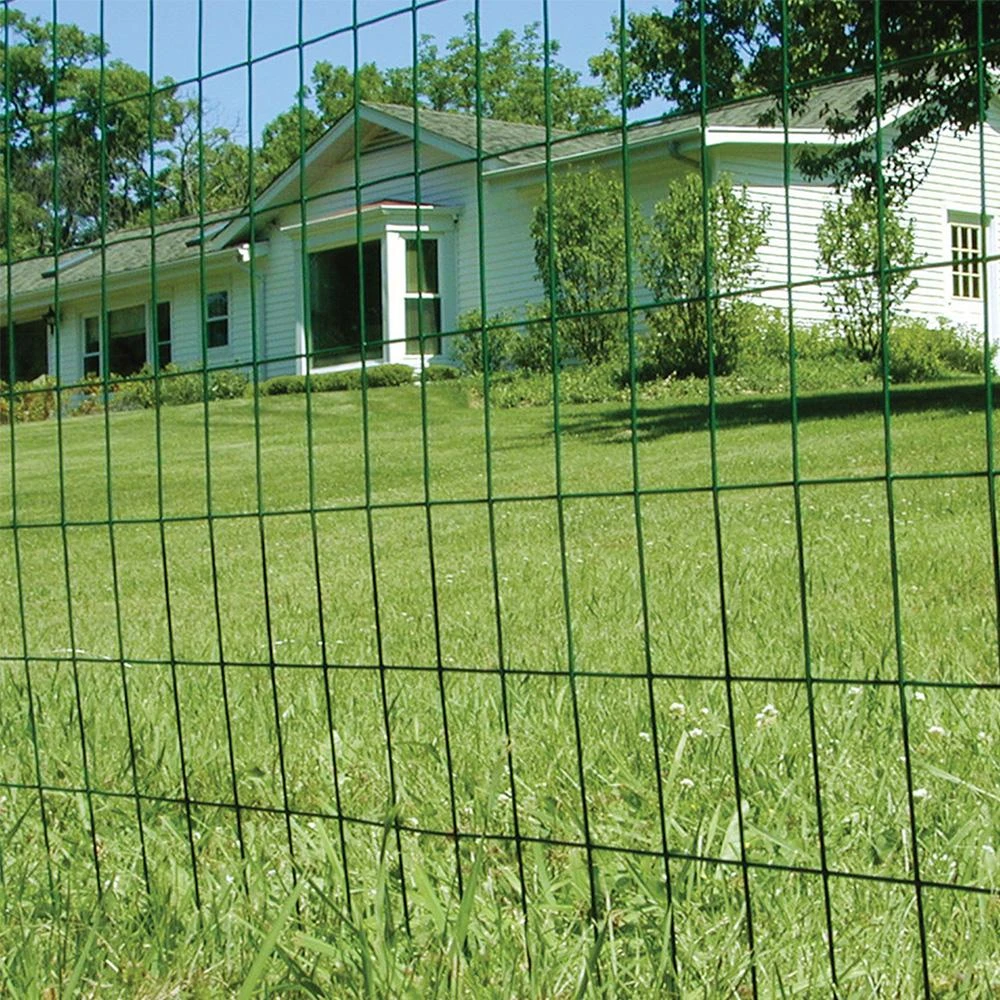

Premium Hot Dip Galvanized Welded Wire Mesh Durable & Corrosion-Resistant

- Understanding Hot Dip Galvanized Welded Wire Mesh Fundamentals

- Technical Advantages and Performance Metrics Analysis

- Leading Industry Manufacturers Comparative Analysis

- Quotation Process and Cost Optimization Strategies

- Custom Specification Development for Specialized Applications

- Field Application Case Studies Across Industries

- Selecting Your Hot Dip Galvanized Welded Wire Mesh Company

(hot dip galvanized welded wire mesh)

Understanding Hot Dip Galvanized Welded Wire Mesh Fundamentals

Hot dip galvanized welded wire mesh represents a critical engineered material fabricated through precise resistance welding techniques followed by comprehensive zinc immersion. This dual-phase manufacturing creates dimensionally stable lattices ranging from 6mm to 150mm aperture sizes. The zinc coating thickness typically exceeds 70μm according to ISO 1461 standards, creating a metallurgical bond that delivers corrosion resistance 5-8 times superior to electroplated alternatives. The hot dip galvanization process provides complete coverage at all intersections - a critical factor where mechanical stress concentrates. This comprehensive protection extends product lifespan to 20-50 years across diverse environmental exposures.

Technical Advantages and Performance Metrics

The thermochemical zinc-iron alloy layers formed during galvanization create a multi-barrier defense system providing both cathodic protection and physical obstruction. Material tests confirm these meshes maintain structural integrity after 3,000 hours of salt spray testing (ASTM B117), while tension tests reveal tensile strength retention exceeding 90% after accelerated aging simulations. The fusion welding process generates consistent joint strength averaging 98% of base wire capacity. Aperture precision tolerance of ±3% ensures exacting dimensional stability critical for automated installation systems. These technical advantages translate to reduced lifecycle costs of 30-45% versus non-galvanized alternatives.

| Property | Standard Grade | Marine Grade | Industrial Grade | Test Method |

|---|---|---|---|---|

| Zinc Coating | 70-85μm | 85-110μm | 90-120μm | ISO 1461 |

| Tensile Strength | 500-600 MPa | 550-650 MPa | 600-750 MPa | ASTM A370 |

| Salt Spray Resistance | 1,500 hrs | 2,500+ hrs | 3,000+ hrs | ASTM B117 |

Leading Industry Manufacturers Comparative Analysis

The global market features distinct tiers of hot dip galvanized welded wire mesh

companies differentiated by technical capabilities. Tier 1 manufacturers typically operate automated kettle galvanizing facilities with minimum production capacities of 500 tons monthly. These leaders utilize robotic welding cells achieving positioning accuracy within 0.15mm, supported by ISO 9001 and CWI certified welding programs. Mid-market specialists often focus on niche applications like hexagonal poultry meshes or architectural elements. Regional fabricators provide accessibility but frequently subcontract galvanizing. The most advanced manufacturers now implement continuous optical measurement systems to maintain wire diameter consistency within ±0.05mm.

| Manufacturer | Production Capability | Lead Time | Quality Certifications | Specialized Offerings |

|---|---|---|---|---|

| Global Mesh Solutions | 850 tons/month | 15-20 days | ISO 9001, CWI | Architectural finishes |

| DuraSteel Fab | 400 tons/month | 20-25 days | ISO 9001 | High-zinc marine grade |

| PreciseGrid Systems | 300 tons/month | 25-35 days | – | Standard commercial |

Quotation Process and Cost Optimization Strategies

Requesting hot dip galvanized welded wire mesh quotes requires precise technical specifications to ensure accurate pricing. Beyond basic dimensions, suppliers need data points including: wire tolerance class (ISO 2232 compliance), mesh orientation requirements, edge condition specifications, and special packaging needs. Commercial quotes typically structure pricing in brackets with quantity breaks at 500m², 1,000m² and 5,000m² thresholds. Steel index surcharges currently contribute 40-55% of base price volatility. Value engineering opportunities exist through optimized aperture designs that can reduce material consumption by 18% without compromising functional requirements.

Custom Specification Development for Specialized Applications

Advanced hot dip galvanized welded wire mesh companies provide technical collaboration for developing application-specific configurations beyond standard catalog offerings. This includes: curved sections for architectural applications using CNC roller forming equipment with ±1° precision; heavy-duty security configurations with 8mm wires at 50x50mm apertures achieving over 1,200N/mm² shear resistance; and composite solutions incorporating PVC overcoating where continuous immersion requires supplementary protection. Custom galvanizing formulations can achieve zinc layers exceeding 150μm for splash zones in marine applications. Dedicated engineering teams typically require 5-7 working days to develop proposals for such specialized configurations.

Field Application Case Studies Across Industries

Petrochemical infrastructure projects demonstrate the exceptional durability of hot dip galvanized welded wire mesh. In offshore platform installations, Type A marine-grade mesh showed less than 5% zinc loss after 7 years in high-salt spray zones while supporting over 15 tons of equipment. Concrete reinforcement applications benefit from the material's uniform current distribution characteristics, as measured in a recent highway project where electrical continuity tests showed less than 0.15 ohm resistance across 50-meter sections. Agricultural installations reveal equally impressive performance - poultry confinement systems withstand repetitive chemical cleaning while maintaining structural integrity beyond 10 years of continuous use.

Selecting Your Hot Dip Galvanized Welded Wire Mesh Company

Identifying the optimal hot dip galvanized welded wire mesh partner requires evaluating multiple technical and commercial parameters beyond basic pricing. Production audit reports should verify process control systems for maintaining welding amperage within ±2% specifications. Independent certification of galvanizing kettle zinc purity (minimum 98.5%) prevents contamination that compromises coating adhesion. Service capability differentiators include just-in-time inventory programs that ensure 95% fulfillment of emergency orders under 72 hours. Leading suppliers now offer digital project portals providing real-time manufacturing progress tracking and automated documentation generation for quality assurance compliance.

(hot dip galvanized welded wire mesh)

FAQS on hot dip galvanized welded wire mesh

Q: Where can I find reliable hot dip galvanized welded wire mesh companies?

A: Reputable hot dip galvanized welded wire mesh companies are typically found through industrial directories like Thomasnet or Alibaba. Manufacturers often specialize in construction or agricultural wire mesh and display certifications like ISO 9001 for quality assurance. Always verify their production capacity and client testimonials for reliability.

Q: How do I get accurate hot dip galvanized welded wire mesh quotes?

A: Submit detailed specifications including mesh size, wire gauge, dimensions, and quantity to suppliers for precise hot dip galvanized welded wire mesh quotes. Material coatings (e.g., zinc thickness) and packaging requirements also impact pricing. Compare quotes from 3-5 verified companies to ensure competitive market rates.

Q: Why choose hot dip galvanized over other welded wire mesh coatings?

A: Hot dip galvanizing provides superior corrosion resistance compared to electro-galvanized coatings, making it ideal for harsh environments like marine or chemical sites. The molten zinc bonds metallurgically with the steel core, ensuring longer product lifespan. This process withstands physical damage better than alternative coatings.

Q: What quality checks should I perform when selecting a hot dip galvanized welded wire mesh company?

A: Verify adherence to international standards like ASTM A123/A123M for zinc coating thickness and uniformity. Inspect weld point strength and dimensional accuracy through sample testing before bulk orders. Reputable companies will provide mill test reports and third-party quality certificates upon request.

Q: How long does production take for custom hot dip galvanized welded wire mesh orders?

A: Standard production lead times range from 2-4 weeks depending on order complexity and manufacturer workload. Custom specifications (e.g., non-standard wire diameters or panel sizes) may extend timelines. Expedited services are often available from established suppliers at additional costs for urgent projects.

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping Xingzhi Metal | Corrosion Resistance, Durability

NewsJul.23,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance,Durable Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security Solution&Temporary Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security, Corrosion Resistance

NewsJul.21,2025

-

Galvanized/PVC Coated Barbed Wire-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance&Durability

NewsJul.21,2025

-

Double Twisted Hexagonal Gabion Mesh Box-Gabion Mattress - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.21,2025