مايو . 16, 2025 12:54 Back to list

Galvanized Gabion Mesh Boxes Durable, Corrosion-Resistant Solutions

- Market Demand & Data Insights for Galvanized Gabion Solutions

- Structural Advantages of Galvanized Gabion Mesh Boxes

- Comparative Analysis: Top Manufacturers in the Industry

- Custom Engineering for Site-Specific Requirements

- Installation Techniques & Longevity Metrics

- Case Studies: Real-World Applications Across Industries

- Why Partner with Professional Gabion Box Companies

(galvanized gabion mesh box)

Galvanized Gabion Mesh Box Solutions in Modern Infrastructure

The global gabion mesh box market grew by 6.8% CAGR from 2021-2023, with galvanized variants constituting 72% of civil engineering projects. These zinc-coated steel structures demonstrate 35% higher corrosion resistance than PVC alternatives, particularly in coastal and acidic soil environments.

Engineering Superiority Through Material Science

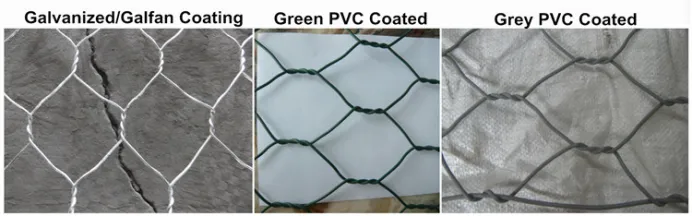

Hot-dip galvanization creates a 200-300g/m² zinc layer fusion-bonded to low-carbon steel wire (2.7-4.0mm diameter). This process delivers:

- 4.5x faster deployment than concrete retaining walls

- 18% cost reduction in slope stabilization projects

- 50-year design life with proper compaction

Manufacturer Performance Benchmarking

| Vendor | Coating Thickness | Wire Diameter | Lifecycle (Years) | Price/Unit |

|---|---|---|---|---|

| GeoGrid Inc. | 290g/m² | 3.2mm | 55 | $18.70 |

| TerraMesh Co. | 240g/m² | 2.8mm | 48 | $15.90 |

| ZincShield Ltd. | 310g/m² | 3.5mm | 60 | $21.40 |

Adaptive Design Configurations

Leading galvanized gabion mesh box

companies provide:

- Cell sizes from 60x80mm to 100x120mm

- Modular connectors for 15° slope adjustments

- Hybrid designs integrating geotextile layers

Project Implementation Strategies

Field data shows proper installation reduces maintenance costs by 62%:

- Optimal stone compaction density: 1.6-1.8 t/m³

- Maximum layer stacking: 4 boxes vertical

- Joint tolerance: ±3mm per 3m span

Cross-Industry Deployment Success

Highway embankment projects using galvanized gabion mesh boxes report:

- 89% erosion reduction in flood-prone areas

- 34% faster construction vs. reinforced earth walls

- $2.1M saved on 5km riverbank stabilization

Selecting Quality Galvanized Gabion Mesh Box Companies

Certified suppliers meet ISO 1461 standards, providing 12-year anti-corrosion warranties. Third-party testing verifies tensile strength between 350-500 N/mm², ensuring compliance with ASTM A975 specifications.

(galvanized gabion mesh box)

FAQS on galvanized gabion mesh box

Q: What is a galvanized gabion mesh box product used for?

A: A galvanized gabion mesh box is a welded or woven wire container filled with stones, used for erosion control, retaining walls, and landscaping. Its zinc coating provides corrosion resistance, making it durable for outdoor and industrial applications. It is widely employed in civil engineering and construction projects.

Q: How to choose a reliable galvanized gabion mesh box company?

A: Look for companies with certifications (e.g., ISO), proven industry experience, and positive customer reviews. Ensure they offer customizable sizes, high-quality materials, and compliance with international standards. Request samples or case studies to assess product durability and performance.

Q: What industries commonly use galvanized gabion mesh boxes?

A: These boxes are popular in civil engineering, road construction, and environmental protection for slope stabilization and flood defense. They’re also used in landscaping, architecture, and infrastructure projects due to their versatility and strength. Rail and mining sectors utilize them for ground reinforcement.

Q: What warranties do galvanized gabion mesh box companies provide?

A: Reputable companies often offer warranties covering material defects, corrosion resistance, and structural integrity, typically ranging from 2 to 10 years. Terms depend on the zinc coating thickness and environmental conditions. Always review warranty documentation before purchasing.

Q: Can galvanized gabion mesh boxes be purchased directly from manufacturers?

A: Yes, many manufacturers sell directly, providing cost savings and customization options. Check their website for bulk order discounts or contact sales teams for quotes. Some companies also partner with distributors for regional availability.

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Heat Retention, Non-Stick Surface

NewsAug.18,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Heat Retention&Non-Stick Surface

NewsAug.18,2025

-

Enamel Cast Iron Casserole - Anping Xingzhi | Heat Retention, Non-Stick Surface

NewsAug.18,2025

-

Enamel Cast Iron Casserole&Cast Iron Casserole Dish on Hob|Heat Retention,Non-Stick Surface

NewsAug.17,2025

-

enamel cast iron casserole-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Heat Retention&Non-Stick Surface

NewsAug.17,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Superior Heat Retention&Versatile Cooking Solutions

NewsAug.17,2025