Sep . 02, 2025 00:20 Back to list

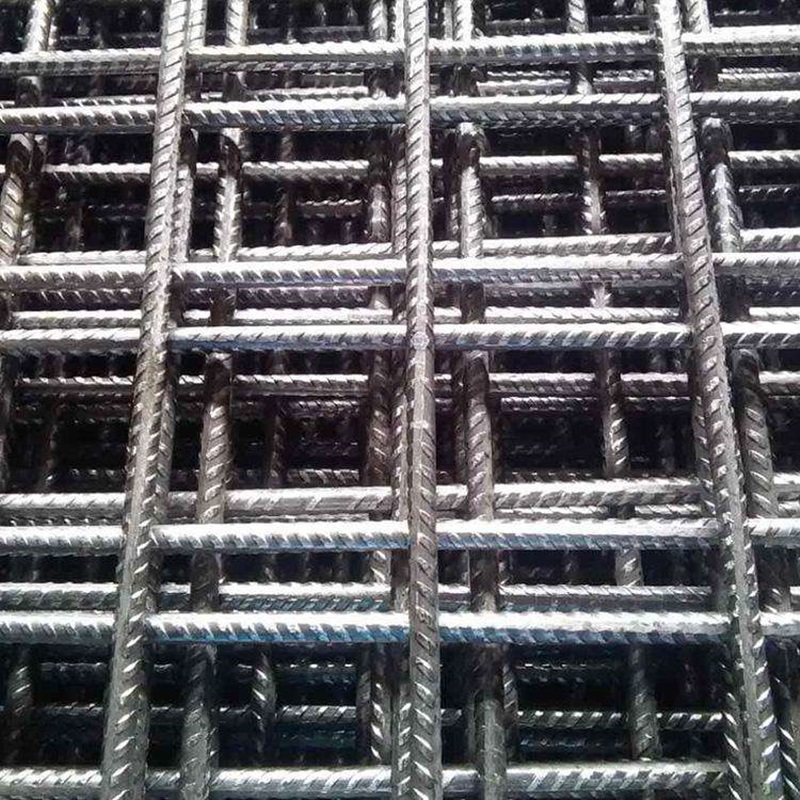

Construction Reinforced Steel Bar Welded Wire Mesh - Strength & Durability

The Evolving Landscape of Reinforcement: Understanding Construction Reinforced Steel Bar Welded Wire Mesh

In the dynamic realm of modern infrastructure development, the efficiency and integrity of structural reinforcement are paramount. Traditional rebar tying methods, while foundational, often present challenges in terms of labor intensity, installation time, and consistency. This landscape is rapidly evolving with the increased adoption of advanced pre-fabricated solutions. One such innovation, the Construction Reinforced Steel Bar Welded Wire Mesh, stands at the forefront of this transformation, offering superior structural performance, enhanced buildability, and significant project cost efficiencies. Industry trends indicate a sustained growth in the demand for engineered mesh products, driven by stringent construction schedules, a focus on seismic resilience, and a global push for more sustainable and efficient building practices. Projects ranging from high-rise commercial buildings to expansive civil engineering works are increasingly specifying welded wire mesh due to its predictable properties and rapid deployment capabilities.

The global market for concrete reinforcement products is projected to expand significantly, with welded wire mesh playing a crucial role. According to recent market analyses, factors such as urbanization, government investments in infrastructure, and technological advancements in manufacturing are propelling this growth. Engineers and procurement professionals are increasingly prioritizing materials that not only meet structural requirements but also contribute to overall project lifecycle value. The precise spacing and secure welding of reinforcing bars in a mesh format minimize potential errors on-site and ensure optimal concrete embedment, leading to more durable and safer structures. Furthermore, the material's ability to be produced to exact specifications reduces material waste, aligning with contemporary environmental and economic objectives.

Precision Manufacturing: The Process Flow of Reinforced Welded Wire Mesh

The production of high-quality Construction Reinforced Steel Bar Welded Wire Mesh is a sophisticated industrial process, meticulously controlled to ensure adherence to stringent engineering specifications. This multi-stage process guarantees the structural integrity and reliability critical for demanding construction applications. Understanding this flow is essential for B2B decision-makers seeking assurance in their material supply chain.

Step 1: Raw Material Sourcing & Inspection

The process begins with the procurement of high-grade steel wire rods, typically conforming to standards like ASTM A615 (for rebar) or ASTM A1064 (for wire reinforcement). These rods undergo rigorous initial inspection for chemical composition, surface defects, and mechanical properties (e.g., tensile strength, yield strength) to ensure they meet specified material grades (e.g., Grade 60, Grade 80). This ensures the foundational quality of the mesh.

Step 2: Wire Drawing & Ribbing/Deformation

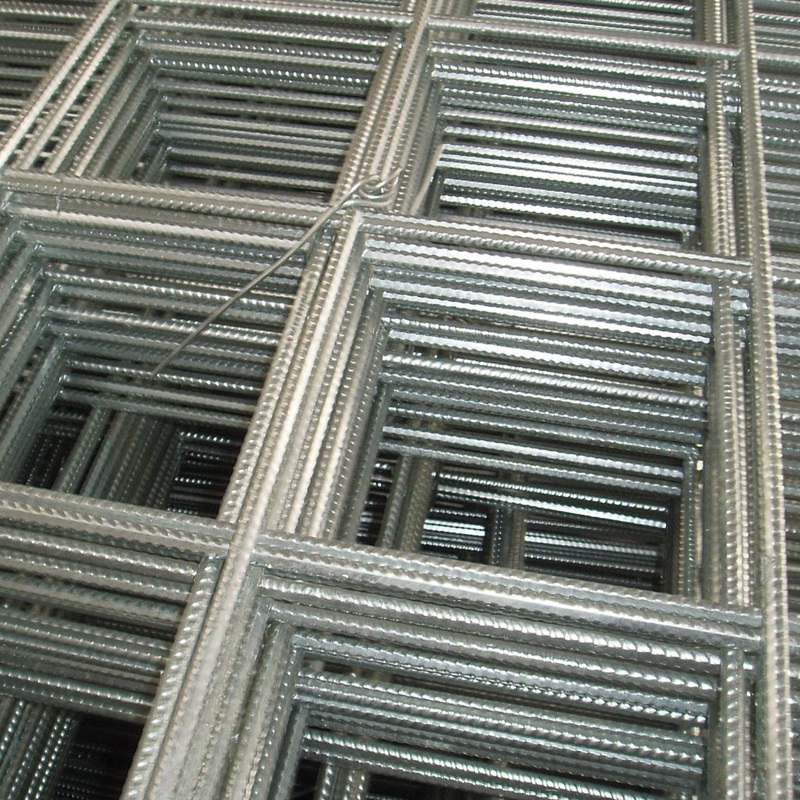

Raw steel rods are drawn through a series of dies to achieve the precise wire diameter required (e.g., from 4mm to 16mm). For deformed wire mesh, the wires then pass through rollers that impart surface deformations (ribs or indentations) as per standards like ASTM A1064/A1064M. These deformations are crucial for enhancing bond strength with concrete, preventing slippage, and improving crack control.

Step 3: Automated Welding & Fabrication

The drawn and deformed wires are fed into automated welding machines. Longitudinal wires are laid out parallel, and transverse wires are placed perpendicularly at precise intervals. Resistance welding or electric resistance welding (ERW) is employed to fuse the wires at their intersections. This CNC-controlled process ensures uniform mesh spacing (e.g., 50mm x 50mm, 100mm x 200mm) and high-strength weld points, critical for weld shear strength and overall mesh integrity.

Step 4: Quality Control & Testing

Throughout and after fabrication, stringent quality control measures are implemented. This includes visual inspection, dimensional checks of mesh size and spacing, and mechanical testing of finished mesh panels. Key tests include tensile strength tests, yield strength tests, elongation tests, and critical weld shear strength tests, all performed in accordance with international standards such as ISO 6935-3 and ASTM A1064/A1064M. Only mesh that passes these rigorous tests is approved for dispatch.

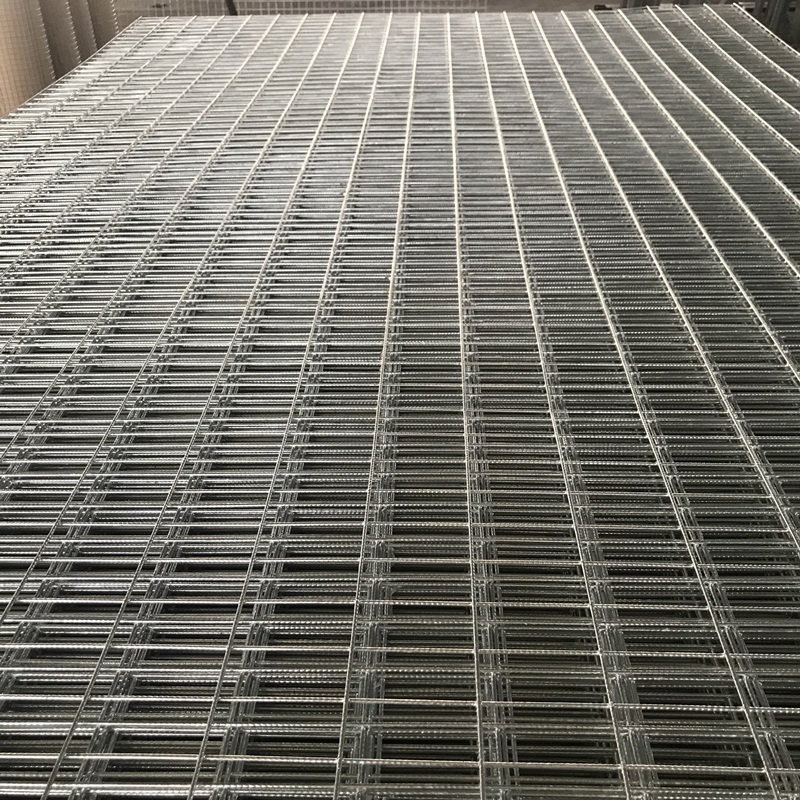

Step 5: Finishing, Bundling & Dispatch

The finished mesh panels are then cut to specified dimensions (e.g., 2.4m x 4.8m sheets) and typically bundled for ease of handling and transport. Surface treatments, if required (e.g., galvanization for corrosion resistance in specific environments), would occur prior to or after cutting. Proper labeling and documentation for traceability are ensured before the product is dispatched to construction sites, ready for immediate installation.

Technical Specifications and Performance Metrics

The efficacy of Construction Reinforced Steel Bar Welded Wire Mesh in various engineering applications hinges on its precise technical specifications and verifiable performance metrics. These parameters dictate the mesh's suitability for specific structural loads, environmental conditions, and design lifespans. Adherence to international standards such as ASTM A1064/A1064M and ISO 6935-3 is crucial for ensuring material reliability and project safety.

Key Product Specifications

These specifications are not merely numbers; they represent the engineered performance that underpins structural stability. For instance, a high yield strength ensures the material can absorb significant stress before permanent deformation, while robust weld shear strength guarantees the mesh acts as a monolithic unit, distributing forces effectively throughout the concrete element. Specifying the correct wire diameter and mesh spacing is critical for achieving the design's required reinforcement ratio and controlling crack propagation, thereby extending the service life of concrete structures. All products are manufactured under strict quality management systems, often certified to ISO 9001:2015, ensuring consistency and traceability from raw material to finished product.

Versatile Applications and Core Technical Advantages

The adaptability and inherent benefits of Construction Reinforced Steel Bar Welded Wire Mesh have positioned it as a preferred choice across a multitude of construction sectors. Its pre-fabricated nature streamlines site operations, making it highly valuable in projects demanding rapid execution and high precision.

Target Industries & Application Scenarios

-

✔

Building Construction: Widely used in concrete slabs for floors, roofs, and precast wall panels. Its consistent mesh size and spacing are critical for maintaining structural integrity and preventing cracking in residential, commercial, and industrial buildings.

-

✔

Infrastructure Projects: Essential for reinforcing roads, highways, airport runways, bridges, tunnels, and retaining walls. It provides superior crack control and enhanced load-bearing capacity, significantly extending the service life of these critical structures.

-

✔

Water Supply & Drainage Systems: Utilized in concrete pipes, culverts, reservoirs, and wastewater treatment plants, where corrosion resistance (if coated) and precise reinforcement are vital for long-term performance in demanding environments.

-

✔

Mining & Tunneling: Applied in shotcrete and concrete lining for ground support, providing immediate and effective reinforcement in challenging underground conditions.

Core Technical Advantages

-

✓

Enhanced Structural Integrity: The factory-welded intersections ensure precise bar spacing and prevent shifting during concrete pouring, leading to a more consistent and predictable reinforcement matrix. This results in superior structural performance compared to hand-tied rebar.

-

✓

Significant Time & Labor Savings: Pre-fabricated mesh panels drastically reduce on-site installation time and labor requirements. A single mesh panel can replace numerous individual rebar pieces, accelerating project schedules and lowering overall construction costs. This contributes to enhanced project profitability and faster return on investment.

-

✓

Superior Crack Control: The uniform distribution of steel reinforcement minimizes crack width and propagation, improving the long-term durability and aesthetic appeal of concrete surfaces. This is particularly crucial in slabs and pavements exposed to thermal expansion and contraction.

-

✓

Reduced Material Waste: Manufactured to precise dimensions, welded wire mesh results in minimal cutting and waste on-site, contributing to more sustainable construction practices and cost savings on material procurement.

-

✓

Enhanced Safety: Less on-site handling of individual rebar pieces reduces the risk of injuries, contributing to a safer work environment for construction personnel.

Strategic Vendor Selection and Tailored Solutions

Choosing the right supplier for Construction Reinforced Steel Bar Welded Wire Mesh is a critical decision that impacts project timelines, costs, and ultimate structural performance. A comprehensive vendor comparison should extend beyond mere pricing to encompass quality assurance, technical expertise, logistical capabilities, and the ability to provide customized solutions.

Key Criteria for Vendor Evaluation

Customized Solutions for Unique Project Demands

Modern construction projects often present unique challenges that standard off-the-shelf mesh products cannot fully address. Leading manufacturers offer comprehensive customization options, ensuring the Construction Reinforced Steel Bar Welded Wire Mesh perfectly integrates with specific design requirements. This bespoke approach minimizes waste, optimizes structural performance, and simplifies on-site assembly.

-

+

Variable Wire Diameters: Longitudinal and transverse wires can be specified with different diameters to match varying stress demands, optimizing material usage.

-

+

Non-Standard Mesh Spacing: Design-specific mesh configurations for highly localized stress areas or specific crack control objectives.

-

+

Tailored Panel Dimensions: Production of panels in precise lengths and widths reduces on-site cutting, minimizing waste and accelerating installation.

-

+

Special Steel Grades & Coatings: Availability of higher strength steels or specialized coatings (e.g., epoxy, galvanized) for corrosive environments or enhanced durability requirements.

Real-World Impact: Case Studies and Client Success

The tangible benefits of Construction Reinforced Steel Bar Welded Wire Mesh are best demonstrated through successful application in real-world projects. These case studies highlight not only the material's performance but also the collaborative expertise of suppliers in achieving project objectives.

Case Study 1: High-Speed Rail Viaduct Construction

Project Scope: Construction of a 15 km elevated viaduct for a new high-speed rail line, requiring vast quantities of concrete for deck slabs and support structures. Traditional rebar methods would have severely hampered the aggressive project schedule.

Solution: Customized Construction Reinforced Steel Bar Welded Wire Mesh panels with varying bar diameters and spacing were specified for different sections of the viaduct deck. The mesh was delivered pre-cut to exact dimensions, minimizing on-site fabrication.

Outcome: The use of welded wire mesh accelerated reinforcement placement by approximately 40% compared to traditional methods, enabling the project to stay ahead of schedule. The precise factory welding ensured high structural integrity and uniform concrete cover, contributing to the projected 100-year design life of the structure. The client reported significant labor cost savings and enhanced safety records.

Case Study 2: Industrial Warehouse Floor Slab

Project Scope: Development of a 50,000 sq. meter industrial warehouse requiring a high-strength, crack-resistant concrete floor slab capable of withstanding heavy point loads from racking systems and continuous forklift traffic.

Solution: A heavy-gauge Construction Reinforced Steel Bar Welded Wire Mesh (e.g., D8/D8 mesh with 150mm x 150mm spacing) was employed, optimized for shrinkage control and load distribution. The mesh was supplied in large format sheets to cover vast areas quickly.

Outcome: The use of welded wire mesh facilitated a rapid pour schedule, with the entire slab completed 25% faster than anticipated. Post-construction inspections revealed excellent crack control and minimal surface imperfections, a crucial factor for warehouse operations. The client praised the supplier's ability to meet tight delivery schedules and provide consistent product quality, resulting in a durable, low-maintenance floor.

Client Testimonial:

"Our partnership with [Supplier Name - e.g., XZ Metal] on the [Project Name] project was instrumental in its success. The precision-engineered Construction Reinforced Steel Bar Welded Wire Mesh not only met our rigorous structural specifications but also dramatically cut down our installation time. Their technical support team provided invaluable assistance, ensuring seamless integration into our construction workflow. We look forward to future collaborations."

– Project Manager, Leading General Contractor

Commitment to Quality, Reliability, and Client Trust

In the B2B sector, trust is built on a foundation of consistent quality, transparent operations, and unwavering support. As a leading provider of Construction Reinforced Steel Bar Welded Wire Mesh, our commitment extends beyond product delivery to fostering long-term partnerships through robust quality assurance, clear warranty commitments, and responsive customer service.

Our Quality Assurance & Authoritative Certifications

Our manufacturing processes are meticulously aligned with international quality management standards, ensuring every panel of welded wire mesh meets the highest benchmarks for strength, durability, and precision. Key certifications and adherence include:

-

✓

ISO 9001:2015 Certified: Demonstrates our commitment to a robust quality management system, covering all stages from raw material procurement to final product inspection and dispatch.

-

✓

Adherence to ASTM A1064/A1064M: Our products strictly comply with the "Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete" issued by the American Society for Testing and Materials, ensuring global compatibility and performance.

-

✓

Rigorous In-House Testing: Beyond external certifications, every batch undergoes extensive mechanical and dimensional testing in our state-of-the-art facilities, backed by detailed test reports and material certificates.

Warranty and After-Sales Support

We stand behind the quality of our Construction Reinforced Steel Bar Welded Wire Mesh with comprehensive warranty commitments. Our products are guaranteed to be free from manufacturing defects and to meet all specified technical parameters upon delivery. Our dedicated after-sales support team is readily available to address any inquiries, provide technical assistance, or facilitate replacements, ensuring continuous client satisfaction and minimizing project disruptions. We pride ourselves on prompt and effective resolution of any post-purchase concerns.

Lead Time & Fulfillment

Understanding the time-sensitive nature of construction projects, we maintain optimized production schedules and efficient logistics. Our typical lead times for standard mesh configurations range from 7 to 14 business days, with expedited options available for urgent requirements. For customized orders, lead times are confirmed upon specification finalization. We work closely with our logistics partners to ensure timely and secure delivery to your project site, anywhere in the world, backed by transparent tracking and communication.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of Construction Reinforced Steel Bar Welded Wire Mesh over traditional rebar tying?

A1: Welded wire mesh offers significant advantages including faster installation, reduced labor costs, precise bar spacing, superior crack control, and minimized material waste. Its pre-fabricated nature ensures consistent quality and speeds up project timelines.

Q2: Can this mesh be customized for specific project requirements?

A2: Absolutely. We offer extensive customization options, including variable wire diameters, non-standard mesh spacings, custom panel dimensions, and specialized steel grades or coatings to perfectly match your project's unique structural and environmental demands.

Q3: What testing standards does your Construction Reinforced Steel Bar Welded Wire Mesh comply with?

A3: Our products comply with stringent international standards, primarily ASTM A1064/A1064M, which governs steel wire and welded wire reinforcement. We also operate under an ISO 9001:2015 certified quality management system, ensuring consistent product quality.

Q4: How does welded wire mesh contribute to construction sustainability?

A4: By being manufactured to precise dimensions, welded wire mesh significantly reduces on-site material waste and scrap. Its efficiency in installation also leads to lower energy consumption and reduced carbon footprint associated with labor and machinery operation, aligning with green building initiatives.

Q5: What is the typical service life of structures reinforced with this mesh?

A5: When properly designed and installed according to engineering specifications and local building codes, structures reinforced with our high-quality Construction Reinforced Steel Bar Welded Wire Mesh can have a service life exceeding 50 to 100 years, depending on the application and environmental exposure.

Conclusion: The Future-Proofing Role of Welded Wire Mesh in Construction

The continued evolution of the construction industry places a premium on materials that offer a harmonious blend of strength, efficiency, and adaptability. Construction Reinforced Steel Bar Welded Wire Mesh unequivocally meets these demands, representing a strategic advancement in concrete reinforcement technology. Its consistent quality, rapid installation capabilities, superior crack control, and potential for extensive customization make it an indispensable component for modern infrastructure and building projects.

As urban landscapes grow denser and infrastructure projects become more complex, the role of pre-fabricated, high-performance reinforcement solutions will only expand. Investing in quality welded wire mesh not only optimizes immediate project costs and timelines but also contributes significantly to the long-term durability, safety, and sustainability of built environments. Partners seeking a reliable, high-performance reinforcement solution backed by robust manufacturing and dedicated support will find Construction Reinforced Steel Bar Welded Wire Mesh to be an intelligent and forward-thinking choice.

References

- American Society for Testing and Materials. (2023). ASTM A1064/A1064M-23, Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete. ASTM International, West Conshohocken, PA.

- International Organization for Standardization. (2015). ISO 9001:2015, Quality management systems – Requirements.

- ACI Committee 318. (2019). Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary. American Concrete Institute, Farmington Hills, MI.

- Concrete Reinforcing Steel Institute. (2020). Manual of Standard Practice. CRSI, Schaumburg, IL.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025