Aug . 23, 2025 00:20 Back to list

Fiberglass Insect Screen & Mosquito Window Mesh - Durable Protection

Introduction to Advanced Screening Solutions

In diverse industrial and commercial environments, the demand for robust, high-performance screening materials is paramount. These materials must offer superior protection against pests, maintain optimal airflow, and withstand harsh environmental conditions while ensuring longevity and minimal maintenance. Our specialized product, the Fiberglass insect screen / Mosquito window mesh, is engineered to meet these rigorous demands. This article delves into the technical intricacies, application versatility, and strategic advantages of our advanced fiberglass screening solutions, tailored for B2B decision-makers and engineering professionals seeking durable and reliable options.

Designed for superior performance and extended service life, our Fiberglass insect screen / Mosquito window mesh integrates cutting-edge material science with precision manufacturing. It serves as a critical component in maintaining environmental control, hygiene, and operational efficiency across a spectrum of industrial sectors, from petrochemical facilities to modern commercial buildings.

Industry Trends and Market Dynamics in Screening Technology

The global market for advanced screening materials is experiencing sustained growth, driven by escalating industrial demands for environmental protection, energy efficiency, and operational safety. Key trends include the adoption of materials offering enhanced durability, UV resistance, fire retardancy, and improved airflow characteristics. There's a particular emphasis on solutions that minimize total cost of ownership through extended service life and reduced maintenance. The push for sustainable and non-toxic materials is also shaping product development, with fiberglass emerging as a preferred choice due to its inert properties and recyclability potential.

Industries are increasingly seeking screening solutions that go beyond basic pest control, offering benefits such as protection against fine particulate matter, improved ventilation without compromising security, and resistance to chemical degradation in corrosive atmospheres. This evolving landscape necessitates materials like Fiberglass insect screen / Mosquito window mesh that can adapt to diverse and demanding application environments, providing robust performance under continuous stress.

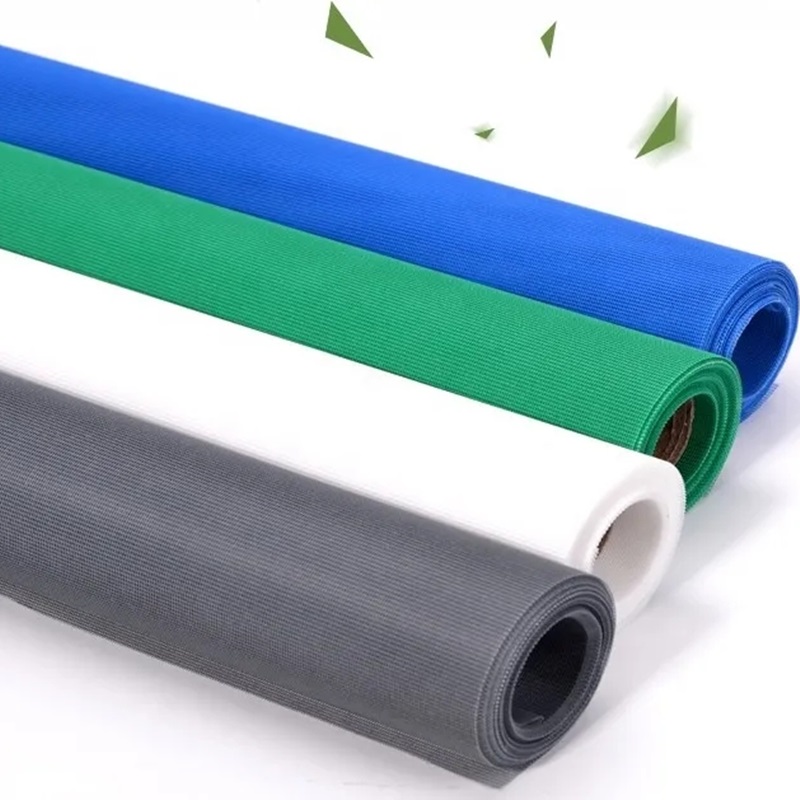

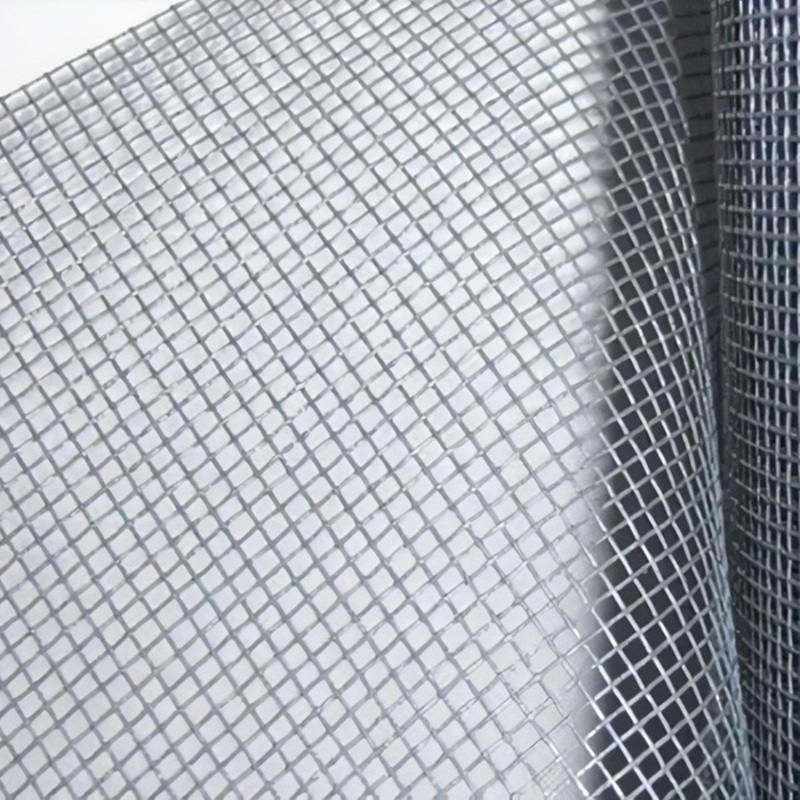

Figure 1: High-performance fiberglass mesh in an industrial setting.

Technical Specifications and Performance Parameters

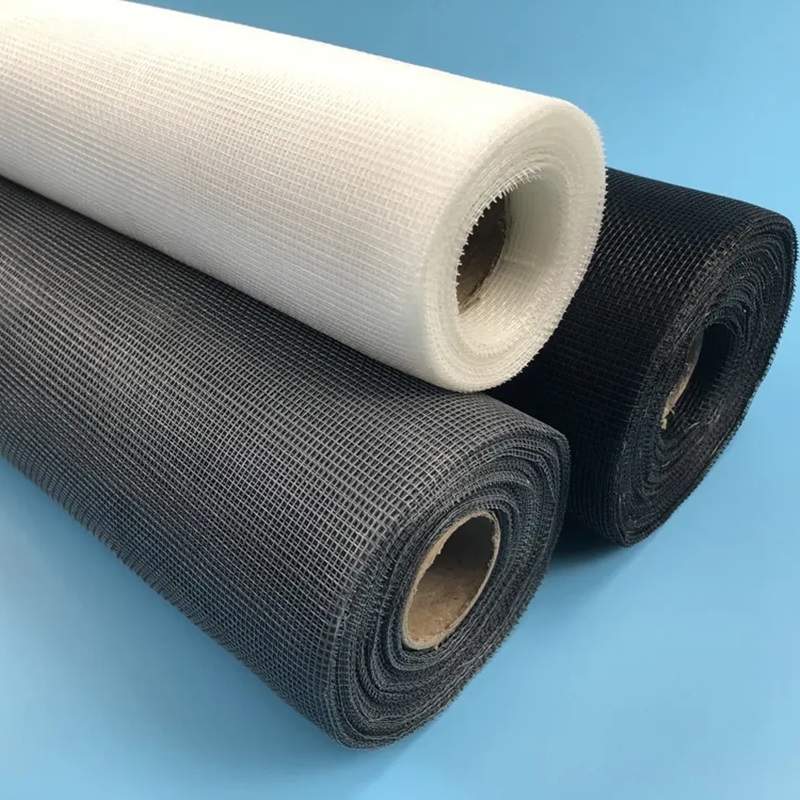

Our Fiberglass insect screen / Mosquito window mesh is meticulously engineered from PVC-coated fiberglass yarn, a composite material renowned for its exceptional strength-to-weight ratio, dimensional stability, and resistance to environmental degradation. The PVC coating acts as a protective barrier, enhancing UV stability, improving tensile strength, and providing an inert surface that resists chemical attack and microbial growth.

Key technical specifications include various mesh counts, typically ranging from 18x16 to 20x20 per inch, with precise yarn diameters (e.g., 0.28mm to 0.33mm) to optimize open area percentages (generally 60-70%). This balance ensures effective insect exclusion while maximizing airflow and maintaining clear visibility. Products adhere to strict quality controls, with testing conducted in accordance with international standards such as ASTM D3656 for tensile and bursting strength, and ISO 9001:2015 for manufacturing processes. Our screens are designed to offer a service life typically exceeding 10-15 years under normal operational conditions, significantly reducing replacement cycles and maintenance costs for our B2B clients.

Typical Product Specifications for Fiberglass Insect Screen

| Parameter | Specification Range | Test Standard |

|---|---|---|

| Material Composition | PVC Coated Fiberglass Yarn (E-Glass) | Internal QA, ISO 9001 |

| Standard Mesh Count | 18x16, 20x20 (threads per inch) | ASTM D3776 |

| Yarn Diameter | 0.28mm - 0.33mm (0.011 - 0.013 inches) | ASTM D1578 |

| Open Area Percentage | 60% - 70% | Internal Calculation |

| Tensile Strength (Warp/Weft) | ≥ 300 N / 50mm | ASTM D3656 |

| Bursting Strength | ≥ 120 PSI | ASTM D3786 |

| UV Resistance (5000h) | Strength Retention ≥ 70% | ASTM G154 |

| Fire Retardancy | Self-extinguishing | UL94 V-0 (material dependent) |

| Temperature Range | -35°C to +80°C | Internal Testing |

Figure 2: Close-up of fiberglass mesh illustrating uniform weave and coating.

Precision Manufacturing Process Flow

The production of our Fiberglass insect screen / Mosquito window mesh follows a meticulously controlled, multi-stage manufacturing process designed to ensure product consistency, superior quality, and adherence to performance specifications. Our process is optimized for efficiency and precision, from raw material sourcing to final packaging.

Detailed Process Steps:

- Fiberglass Yarn Preparation: We begin with high-quality E-glass fiberglass filaments, chosen for their inherent strength and chemical resistance. These filaments are twisted into yarns of specified denier and strength, ensuring uniformity critical for subsequent weaving.

- PVC Coating Application: The prepared fiberglass yarns undergo a sophisticated PVC coating process. This involves drawing the yarn through a specialized liquid PVC bath, followed by precise heat curing. This step imbues the yarn with critical properties: enhanced UV resistance, improved flexibility, fire retardancy, and a smooth, consistent surface finish. The coating thickness is rigorously controlled to maintain optimal mesh integrity and open area.

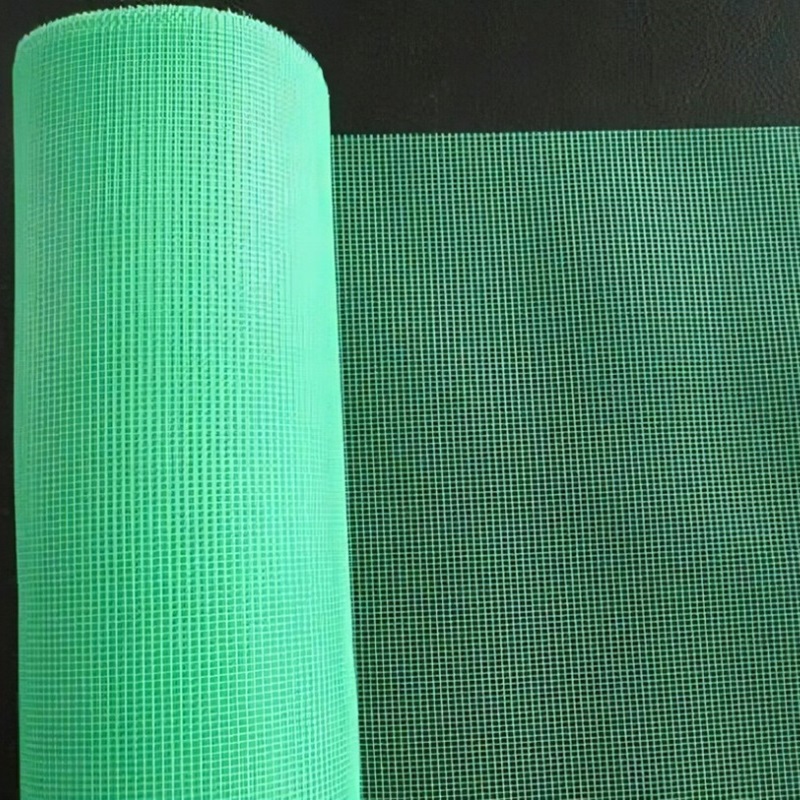

- Precision Weaving: The coated yarns are then fed into advanced weaving looms. Utilizing a plain weave pattern, warp and weft yarns are interlocked to form a stable, uniform mesh structure. The looms are equipped with high-precision controls to maintain consistent mesh count and weave tension across the entire width of the fabric, preventing distortions and ensuring dimensional stability. This is a critical departure from methods like casting or forging, as weaving is specific to textile-like materials.

- Heat Setting and Curing: After weaving, the mesh undergoes a final heat setting process. This step stabilizes the PVC coating, locks the mesh structure, removes any residual stresses from weaving, and ensures the material achieves its ultimate dimensional stability and performance characteristics. This stage is crucial for preventing unraveling and enhancing durability.

- Quality Control and Inspection: Every roll of finished mesh undergoes comprehensive quality inspection. This includes automated optical scanning for weave defects, manual checks for material consistency, and laboratory testing for parameters such as tensile strength, bursting strength, mesh count accuracy, and UV resistance, all in accordance with ISO and ASTM standards.

- Slitting, Rolling, and Packaging: Approved mesh rolls are precisely slit to customer-specified widths and then tightly rolled onto durable cores. Each roll is carefully packaged to protect it during transit and storage, ensuring it arrives in pristine condition, ready for installation.

Figure 3: Advanced weaving machinery for fiberglass mesh production.

Technical Advantages and Performance Benchmarks

The inherent properties of fiberglass, combined with our advanced PVC coating and weaving processes, endow our Fiberglass insect screen / Mosquito window mesh with a suite of technical advantages that are critical for demanding industrial and commercial applications.

- Superior Corrosion Resistance: Unlike metal screens, fiberglass is non-corrosive and immune to rust, oxidation, and galvanic corrosion. This makes it ideal for coastal environments, chemical processing plants, and areas with high humidity or exposure to aggressive industrial atmospheres.

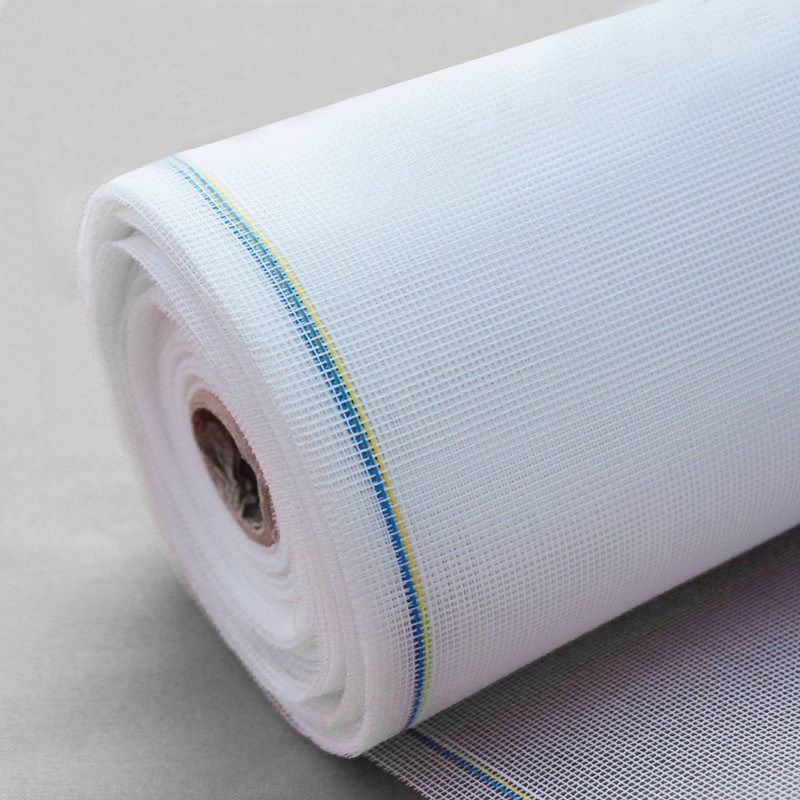

- Exceptional UV Stability and Weather Resistance: The PVC coating provides robust protection against prolonged exposure to ultraviolet radiation, preventing material degradation, fading, and brittleness. This ensures long-term performance in outdoor applications and extreme weather conditions.

- High Tensile Strength and Dimensional Stability: The woven fiberglass structure provides remarkable tear and burst strength, resisting damage from impacts, tension, and environmental stresses. Its dimensional stability prevents sagging or stretching over time, maintaining consistent mesh integrity.

- Optimized Airflow and Visibility: Engineered with a precise open area, the mesh maximizes air circulation while offering excellent outward visibility, crucial for ventilation systems and observation points in industrial facilities.

- Fire Retardancy: The PVC coating imparts self-extinguishing properties, significantly enhancing safety in commercial and industrial settings where fire hazards are a concern.

- Energy Saving: By effectively blocking insects and airborne debris while maintaining excellent airflow, our screens can contribute to energy efficiency by supporting natural ventilation and reducing reliance on HVAC systems for air quality maintenance, particularly in large industrial spaces.

Comparative Performance: Fiberglass vs. Other Materials

| Feature | Fiberglass (PVC Coated) | Aluminum Mesh | Plastic (Polypropylene) Mesh |

|---|---|---|---|

| Corrosion Resistance | Excellent (No Rust) | Good (Can Oxidize) | Excellent |

| UV Stability | Excellent | Very Good | Poor (Degrades) |

| Tensile Strength | High | Medium-High | Low-Medium |

| Fire Retardancy | Self-Extinguishing | Non-Combustible | Flammable |

| Flexibility | Good | Low (Creases Easily) | Excellent |

| Ease of Installation | Very Easy | Medium (Can Dent) | Very Easy |

Figure 4: Durability testing of fiberglass mesh against environmental factors.

Application Scenarios Across Target Industries

The robust and versatile nature of Fiberglass insect screen / Mosquito window mesh makes it indispensable across a range of demanding industrial and commercial sectors. Its unique combination of properties addresses specific challenges faced by these industries.

- Petrochemical Industry: In chemical plants and refineries, our screens are used in ventilation systems for control rooms, equipment enclosures, and storage areas. Their non-corrosive properties are critical in environments with exposure to aggressive chemicals and fumes. The fine mesh prevents insect ingress, which can interfere with sensitive instrumentation or compromise sterile environments, while promoting vital air exchange.

- Metallurgy and Heavy Manufacturing: Foundries and fabrication plants require effective barriers against airborne dust, debris, and insects, which can impact machinery operation and product quality. Fiberglass mesh offers superior resistance to heat and sparks compared to standard plastic, and its durability withstands harsh industrial conditions, protecting personnel and precision equipment.

- Water Supply & Drainage Systems: While not a primary filter media, our screens are invaluable as protective covers for intake and outflow vents, overflow outlets, and inspection ports in water treatment facilities, pump stations, and drainage networks. They prevent larger debris, insects, and small animals from entering and potentially clogging or damaging sensitive infrastructure, thereby reducing maintenance and operational downtime.

- Commercial Buildings and Warehouses: Large commercial facilities, distribution centers, and food processing plants benefit from fiberglass screens for comprehensive pest control. The non-toxic, easy-to-clean material helps maintain hygiene standards, prevent product contamination, and improve employee comfort and productivity.

- Data Centers and Electrical Enclosures: For critical infrastructure requiring continuous airflow and protection from foreign objects, our screens provide optimal ventilation while preventing insect and debris ingress that could lead to overheating or short circuits.

Figure 5: Fiberglass mesh installed in a large industrial ventilation system.

Customized Solutions and Tailored Engineering

Recognizing that every industrial application has unique requirements, we offer extensive customization options for our Fiberglass insect screen / Mosquito window mesh. Our engineering team collaborates closely with clients to develop bespoke solutions that precisely match their operational needs and environmental conditions.

- Mesh Size and Yarn Diameter: We can adjust mesh count and yarn thickness to achieve specific open area percentages, optimizing for factors such as insect exclusion, fine particulate filtration, or maximum airflow.

- Roll Widths and Lengths: Custom dimensions are available to minimize waste and streamline installation for large-scale projects or specific window/ventilation system designs.

- Color Customization: While standard colors like black and gray offer optimal visibility, we can provide custom colors to match architectural aesthetics or comply with specific facility branding guidelines.

- Specialty Coatings: For highly specialized applications, we can integrate additional coatings, such as antimicrobial treatments for healthcare or food processing environments, or enhanced chemical-resistant coatings for particularly aggressive industrial settings.

Our agile manufacturing capabilities allow us to respond efficiently to unique project specifications, delivering tailored solutions without compromising on quality or lead times.

Application Case Studies & Client Successes

Our commitment to quality and performance is consistently demonstrated through successful deployments across diverse industrial landscapes. These case studies highlight the tangible benefits our Fiberglass insect screen / Mosquito window mesh brings to our clients.

Case Study 1: Petrochemical Facility Ventilation Upgrade

A major petrochemical complex in a coastal region faced persistent issues with corrosion and insect ingress in its control room and equipment ventilation openings. Traditional aluminum screens corroded rapidly due to saline air and chemical fumes, leading to frequent replacements and compromising internal air quality. Upon consultation, we provided a customized Fiberglass insect screen / Mosquito window mesh solution (20x20 mesh, reinforced PVC coating) for all critical vents. The result was a dramatic reduction in corrosion-related maintenance, complete elimination of insect intrusion, and improved indoor air quality. The client reported significant operational savings and enhanced equipment longevity.

Case Study 2: Large-Scale Food Processing Plant Pest Control

A leading food processing facility required an upgrade to its entire building envelope to meet stringent hygiene regulations and eliminate pest vectors. Existing screens were brittle, hard to clean, and failed to adequately block smaller insects. We engineered and supplied over 15,000 square meters of our specialized Fiberglass insect screen / Mosquito window mesh with an antimicrobial coating. The fine mesh (20x20) effectively prevented the entry of all common insects, while the antimicrobial properties inhibited bacterial growth on the screen surface. The flexibility and ease of installation allowed for rapid deployment, and the client noted a significant improvement in their pest management audit scores and overall facility hygiene.

Case Study 3: Water Treatment Plant Debris Protection

A municipal water treatment plant struggled with debris and small animals entering their overflow channels and vent shafts, causing blockages and requiring frequent manual clearing. The damp, humid environment also led to rapid degradation of standard screen materials. Our Fiberglass insect screen / Mosquito window mesh (18x16 mesh, robust yarn diameter) was selected for its non-corrosive nature and resistance to moisture and mildew. Installed as protective barriers, the screens effectively prevented debris accumulation and animal entry, drastically reducing maintenance cycles and improving the reliability of the plant's auxiliary systems. The client praised the long-term durability and minimal need for intervention.

Vendor Comparison and Selection Criteria

Selecting the right supplier for Fiberglass insect screen / Mosquito window mesh is crucial for ensuring product performance, supply chain reliability, and project success. Key criteria for vendor evaluation extend beyond mere price, focusing on long-term value and partnership.

- Quality Certifications: A reputable vendor will hold international quality management certifications such as ISO 9001:2015, demonstrating adherence to stringent manufacturing and quality control processes.

- Technical Expertise & R&D: Look for vendors with deep product knowledge, in-house R&D capabilities, and a willingness to provide detailed technical data, test reports, and engineering support for customized solutions.

- Manufacturing Capacity & Lead Times: Assess the vendor's ability to handle large-volume orders and consistently meet agreed-upon lead times, critical for project timelines.

- Customer Support & After-Sales Service: Evaluate the availability of responsive customer service, technical assistance during installation, and clear channels for warranty claims or product inquiries.

- Industry Experience & Reputation: Prioritize suppliers with a proven track record in your specific industry, backed by positive client testimonials and long-standing partnerships.

Our extensive experience, adherence to global standards, and focus on customer-centric solutions position us as a trusted partner for your industrial screening needs.

Trustworthiness and Company Commitments ()

Building trust and demonstrating authority are cornerstones of our B2B relationships. We adhere to the highest standards of expertise, experience, authoritativeness, and trustworthiness () in all aspects of our operations.

- Authoritative Certifications: We are proud to be ISO 9001:2015 certified, affirming our robust Quality Management System in the design, development, production, and service of our fiberglass screening products. Our products consistently meet or exceed relevant ASTM and ANSI standards.

- Proven Track Record: With over [X, e.g., 20] years of specialized experience in manufacturing and supplying advanced screening solutions, we have built long-term partnerships with leading enterprises across petrochemical, metallurgical, and water treatment sectors globally. Our extensive client portfolio, while confidential, includes industry leaders who rely on our consistent quality and innovative solutions.

- Transparent Lead Time & Fulfillment: We provide clear, realistic lead times tailored to order complexity and volume. Our logistics network ensures efficient and reliable fulfillment, with robust tracking and communication throughout the shipping process.

- Comprehensive Warranty Commitment: All our Fiberglass insect screen / Mosquito window mesh products are backed by a comprehensive warranty, typically covering manufacturing defects and material degradation for a specified period (e.g., 5-10 years), reflecting our confidence in product durability and performance.

- Dedicated Customer Support: Our expert customer support team is available to provide technical assistance, product recommendations, and after-sales service. We offer multi-channel support including phone, email, and dedicated account managers to ensure prompt and effective resolution of any inquiries.

Figure 6: Our commitment to quality and precise manufacturing.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of your Fiberglass insect screen / Mosquito window mesh?

A1: Under normal operational conditions, our screens typically have a service life exceeding 10-15 years. This longevity is attributed to the high-quality PVC coating and robust fiberglass core, which provide exceptional UV and weather resistance.

Q2: How should Fiberglass insect screen / Mosquito window mesh be cleaned and maintained?

A2: Our screens are low-maintenance. Regular cleaning with mild soap and water, applied with a soft brush or cloth, is usually sufficient to remove dust and debris. Avoid harsh abrasive cleaners or high-pressure washing, which could damage the coating.

Q3: Are custom mesh sizes or colors available for industrial projects?

A3: Yes, we offer extensive customization options, including various mesh counts, yarn diameters, roll widths, and lengths. Custom color matching and specialized coatings (e.g., antimicrobial) are also available upon request to meet specific project requirements.

Q4: What fire resistance ratings does the fiberglass mesh typically hold?

A4: The PVC coating on our fiberglass mesh imparts self-extinguishing properties, which contributes to enhanced safety. Specific fire resistance ratings can vary by product variant and specific regulatory requirements, but the material generally meets or exceeds common industrial fire safety standards, often aligning with UL94 V-0 for the PVC material component.

Q5: Is your Fiberglass insect screen / Mosquito window mesh suitable for coastal or highly corrosive environments?

A5: Absolutely. Fiberglass is inherently non-corrosive, and our PVC coating further enhances its resistance to salt spray, humidity, and various chemical agents. This makes it an ideal choice for coastal regions, chemical processing plants, and other aggressive industrial atmospheres where metal screens would quickly degrade.

Conclusion

The Fiberglass insect screen / Mosquito window mesh represents a critical advancement in industrial and commercial screening technology. Its superior technical specifications, combined with our rigorous manufacturing processes and commitment to quality, provide a durable, high-performance solution for diverse challenging environments. From enhancing operational efficiency in petrochemical plants to ensuring hygiene in food processing facilities and protecting vital infrastructure in water treatment, our screens deliver unparalleled value. Partner with us to leverage cutting-edge material science and tailored engineering for your next project, ensuring long-term reliability and optimal performance.

References

- ASTM International. (n.d.). _ASTM D3656: Standard Specification for Insect Screening and Louver Cloth Woven from Vinyl-Coated Fiberglass Yarn_. Retrieved from astm.org

- ISO. (n.d.). _ISO 9001:2015 Quality Management Systems – Requirements_. Retrieved from iso.org

- Fibre Reinforced Plastics (FRP). (n.d.). _Properties of Fiberglass_. Retrieved from composite.about.com (conceptual reference for general fiberglass properties)

- UL Standards & Engagement. (n.d.). _UL 94, the Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances testing_. Retrieved from ul.com (conceptual reference for fire safety standards)

- Environmental Protection Agency (EPA). (n.d.). _Indoor Air Quality (IAQ)_. Retrieved from epa.gov (conceptual reference for air quality importance)

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025