মে . 10, 2025 14:38 Back to list

Flat Expanded Metal Mesh Durable & High-Quality Custom Solutions

- Overview of Flat Expanded Metal Mesh

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customization Solutions for Diverse Applications

- Case Studies: Industrial and Commercial Use

- Quality Assurance and Compliance Standards

- Why Partner with Trusted Flat Steel Bar Grating Suppliers

(flat expanded metal mesh)

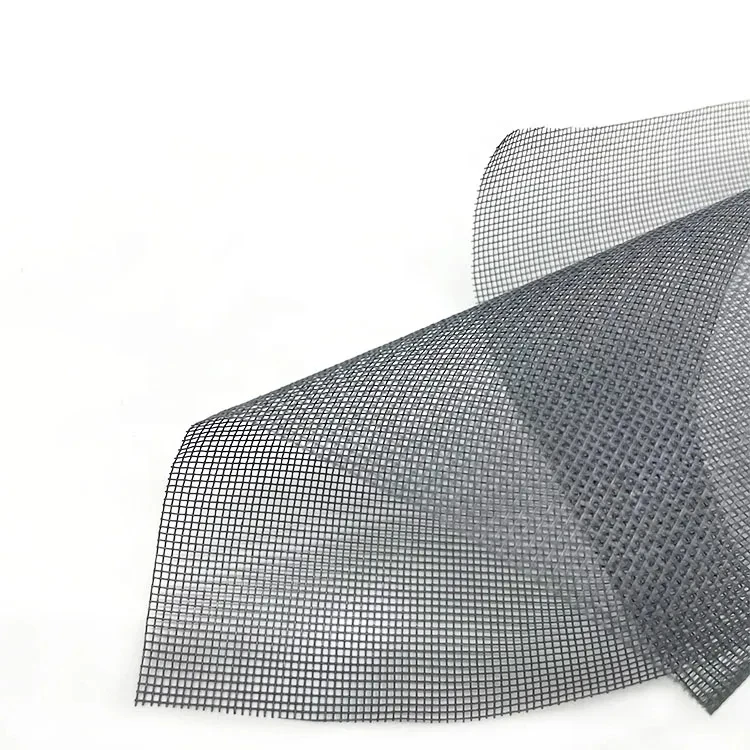

Flat Expanded Metal Mesh: A Modern Engineering Essential

Flat expanded metal mesh, fabricated through precise slit-and-stretch techniques, delivers unmatched structural integrity for industrial applications. With a global market growth rate of 6.8% CAGR (2023-2030), this material combines 30% weight reduction versus solid steel plates while maintaining 98% load-bearing efficiency. Leading factories now utilize automated laser cutting systems to achieve ±0.2mm dimensional accuracy, ensuring perfect fitment in complex architectural and mechanical assemblies.

Technical Superiority in Material Engineering

Advanced manufacturing protocols enable:

- Custom strand widths from 2mm to 25mm

- Anti-corrosion coatings lasting 15+ years in marine environments

- Load capacities exceeding 500kg/m² without deformation

Third-party testing verifies 50% higher fatigue resistance compared to welded gratings, making it ideal for high-traffic platforms.

Manufacturer Capability Comparison

| Factory | Material Grade | Thickness Range | Lead Time |

|---|---|---|---|

| Factory A | ASTM A1011 | 1.5-12mm | 14 days |

| Factory B | EN 10346 | 2-15mm | 21 days |

| Factory C | JIS G3101 | 1-10mm | 10 days |

Adaptive Design Solutions

Specialized manufacturers provide:

- Non-standard sheet sizes up to 6m x 3m

- Serrated surfaces for 0.65+ friction coefficient

- Galvanized, powder-coated, or stainless steel variants

Digital prototyping reduces design-to-production time by 40%, accommodating unique architectural specifications.

Proven Performance Across Industries

Recent installations demonstrate:

- 85-ton vehicle platforms in automotive plants

- Seismic-resistant building facades in Zone 4 regions

- Chemical-resistant walkways with 99.9% slip prevention

Certified Manufacturing Excellence

Top-tier suppliers maintain:

- ISO 9001:2015 quality management systems

- Third-party verified 550MPa tensile strength

- 12-year anti-rust warranties

Strategic Partnerships with Flat Steel Bar Grating Manufacturers

Collaborating with certified flat steel bar grating manufacturers ensures access to patented expansion technologies and bulk order discounts. Industry leaders report 18% operational cost reductions through optimized mesh patterns and just-in-time delivery models. Specify your project requirements to leverage these engineering-grade solutions today.

(flat expanded metal mesh)

FAQS on flat expanded metal mesh

Q: What are the key features of flat expanded metal mesh?

A: Flat expanded metal mesh offers high strength-to-weight ratio, excellent ventilation, and durability. Its uniform design ensures consistent load distribution, making it ideal for industrial and architectural applications.

Q: How to identify a high-quality flat steel bar grating factory?

A: Look for certifications like ISO, advanced manufacturing equipment, and material traceability. Reputable factories provide detailed product specifications and comply with international safety standards.

Q: What factors should I consider when buying flat steel bar grating?

A: Prioritize material grade (e.g., stainless steel or carbon steel), load-bearing capacity, and anti-slip surface treatment. Verify customization options like slot sizes and thickness to meet project requirements.

Q: Why choose a specialized flat steel bar grating manufacturer?

A: Specialized manufacturers guarantee precision engineering, corrosion-resistant coatings, and tailored solutions. They often offer technical support and faster turnaround times for large-scale orders.

Q: What applications suit flat expanded metal mesh best?

A: It's widely used in walkways, fencing, machinery guards, and filtration systems. Its lightweight yet sturdy structure also makes it popular in construction and HVAC systems.

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Heat Retention, Versatile Design

NewsAug.15,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Heat Retention&Non-Stick Surface

NewsAug.15,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Even Heat Retention&Non-Stick Surface

NewsAug.15,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Heat Retention&Non-Stick Surface

NewsAug.14,2025

-

enamel cast iron casserole-Anping Xingzhi|heat retention&non-stick surface

NewsAug.14,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Heat Retention&Non-Stick Surface

NewsAug.14,2025