ag. . 21, 2024 18:47 Back to list

Expanded Metal Sheet Pricing Information and Cost Guide

Understanding Expanded Metal Sheet Pricing A Comprehensive Guide

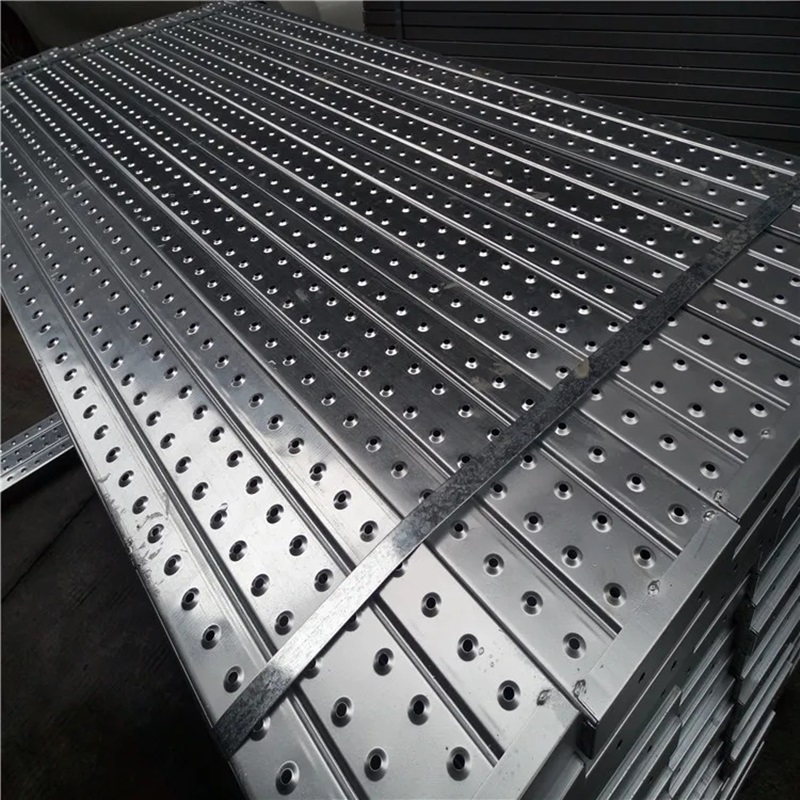

Expanded metal sheets have emerged as a versatile building material favored in various industries, from construction to automotive applications. Their unique design, created by slicing and stretching a solid metal sheet, results in a network of diamond-shaped openings that provide strength while allowing for ventilation and light penetration. As the demand for expanded metal sheets grows, understanding their pricing structure becomes essential for businesses and consumers alike.

Factors Influencing Pricing

1. Material Type One of the primary determinants of expanded metal sheet pricing is the type of metal used. Common materials include aluminum, steel (carbon, stainless), and copper. Each metal has distinct properties such as weight, corrosion resistance, and strength, which influence costs. For instance, stainless steel sheets tend to be more expensive due to their durability and resistance to rust.

2. Sheet Thickness and Size The thickness of the expanded metal sheet significantly affects its price. Thicker sheets require more raw material and processing, making them costlier. Additionally, the dimensions of the sheet contribute to pricing; larger sheets may cost more due to increased material and transportation challenges. Custom sizes can also drive up costs as they often involve additional processing.

3. Mesh Pattern and Hole Size Expanded metal sheets can be produced with various mesh patterns and hole sizes, tailored for specific applications. Finer mesh patterns, which offer more intricate designs or greater filtration, may come at a premium. Conversely, standard patterns are typically more affordable due to their widespread availability.

expanded metal sheet pricelist

4. Production Method The method used to manufacture expanded metal sheets can impact pricing. Standard production methods may yield lower costs, while advanced techniques designed for high precision or customized features can elevate prices. It is important for buyers to understand the production process as it can significantly influence both the quality and cost of the final product.

5. Market Demand and Supply Chain Factors Like any commodity, the market dynamics of supply and demand play a crucial role in setting prices. Periods of high demand, such as during construction booms, often lead to increased pricing. Additionally, fluctuations in raw material costs due to global market conditions can cause prices to vary.

Cost Benefits of Expanded Metal Sheets

While expanded metal sheets can appear to be a significant investment initially, they often prove cost-effective over time. Their durability and resistance to wear and corrosion lead to lower maintenance costs, making them a wise choice for long-term applications. Furthermore, their lightweight nature can reduce transportation expenses and ease installation processes, adding to their economic advantages.

Conclusion

When considering the purchase of expanded metal sheets, it is vital to clearly understand the factors that influence pricing. Potential buyers should carefully evaluate material type, thickness, mesh pattern, production methods, and market conditions to make informed purchasing decisions. As industries continue to recognize the versatility and advantages of expanded metal sheets, staying informed about pricing trends and market dynamics will be essential. Investing in these materials not only yields immediate benefits but also results in long-term savings and superior performance in various applications.

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025

-

Galvanized Iron Wire Anti Mosquito Window Screen Net | Durable

NewsAug.03,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing Solutions&Customizable Construction Site Security

NewsAug.02,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

NewsAug.02,2025