Nov . 23, 2024 00:58 Back to list

welded mesh panel factories

Understanding Welded Mesh Panel Factories An Overview

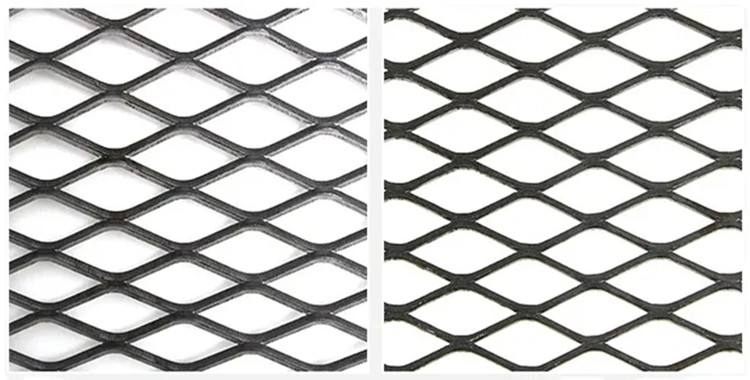

Welded mesh panels are an essential component in various industries, from construction to agriculture and industrial sectors. These panels are created by the welding together of wire strands at their intersections, forming a sturdy grid used for reinforcement, enclosures, and numerous other applications. The importance of welded mesh panel factories lies not only in their production capabilities but also in the quality and versatility of the products they offer.

The Manufacturing Process

Welded mesh panels are produced through a systematic process that begins with the selection of high-quality raw materials. Typically made from carbon steel or stainless steel, the wires are drawn to the required gauge and then cut to standardized lengths. Once the wires are prepared, they are arranged in a grid format. Advanced machines apply high-frequency welding to fuse the wires at their intersections, ensuring a strong bond that can withstand significant tension and pressure.

After the welding process, the mesh panels undergo various treatments to enhance their durability. This may include galvanizing to prevent rust, coating with polymer for added protection, or applying other finishes that suit specific environmental conditions. Quality control measures are crucial during this stage, as factories strive to ensure that each panel meets the necessary standards and specifications.

Applications of Welded Mesh Panels

The versatility of welded mesh panels makes them suitable for a wide range of applications. In the construction industry, they are commonly used for reinforcing concrete structures, providing strength and stability to floors, walls, and other elements. In agricultural settings, these panels serve as fencing for livestock and enclosures for crops, promoting security and growth.

welded mesh panel factories

In industrial environments, welded mesh panels can be seen in safety barriers, storage cages, and security fencing. Their ability to withstand heavy loads and resist corrosion makes them ideal candidates for protecting sensitive equipment and areas. Additionally, welded mesh is increasingly used in architectural applications, adding both aesthetic appeal and structural integrity to buildings.

Choosing the Right Factory

When selecting a welded mesh panel factory, several factors should be considered. Quality assurance is paramount, so it's essential to choose a manufacturer that adheres to international standards for production and testing. Assessing the factory's reputation, customer service, and delivery timelines can also provide insight into their reliability.

Furthermore, the ability of the factory to offer custom solutions can be a significant advantage. Many businesses require specific dimensions, hole sizes, or finishes, and finding a factory that can accommodate these needs is crucial for project success.

Conclusion

In conclusion, welded mesh panel factories play a vital role in supplying high-quality materials that support various industries. With advancements in manufacturing technology, these factories are better positioned to meet the growing demands for versatile and durable welded mesh solutions. Understanding the manufacturing process, applications, and selection criteria can help businesses make informed decisions, ensuring they partner with the right factory for their needs. As industries continue to evolve, the demand for quality welded mesh panels is expected to grow, solidifying the importance of these factories in the global market.

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025

-

Galvanized Iron Wire Anti Mosquito Window Screen Net | Durable

NewsAug.03,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing Solutions&Customizable Construction Site Security

NewsAug.02,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

NewsAug.02,2025