Sep . 29, 2025 22:15 Back to list

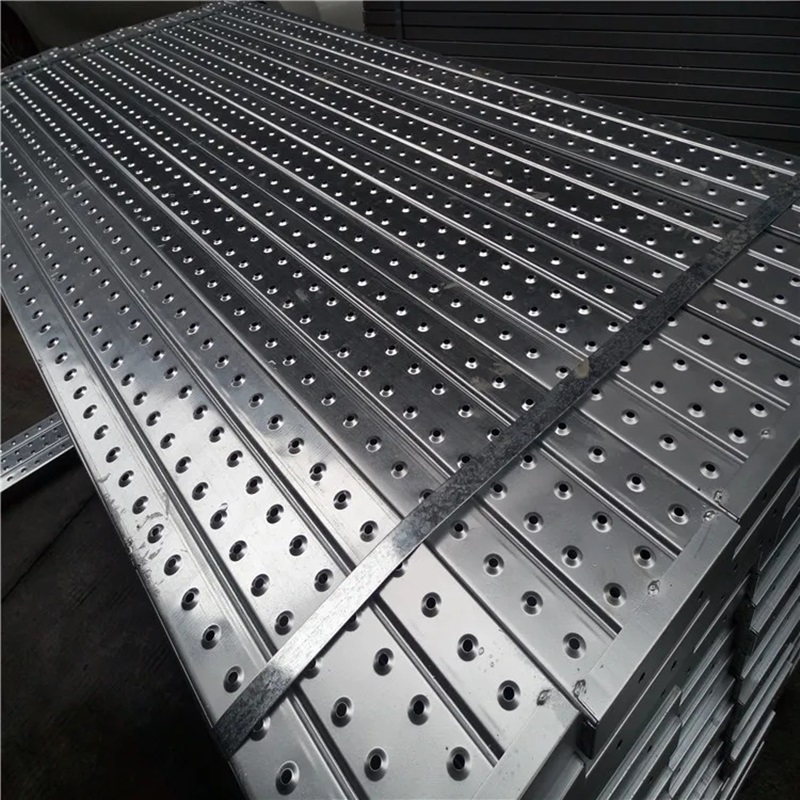

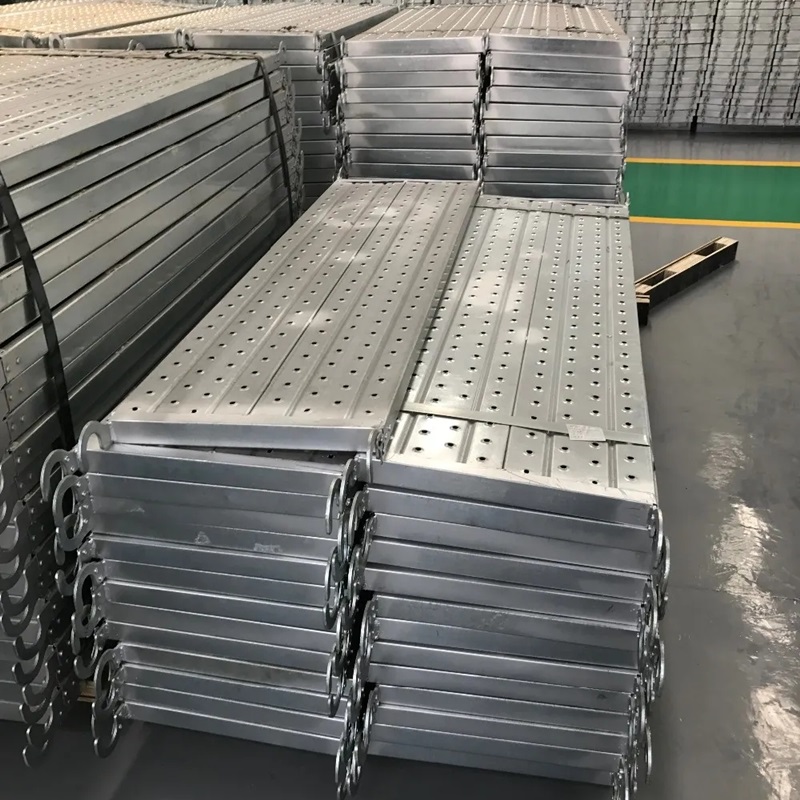

Galvanized construction Scaffold metal plank - Anti-slip

Practical Guide to Galvanized construction Scaffold metal plank

Scaffold teams keep telling us the same thing: reliability beats everything. And, to be honest, that’s exactly where a Galvanized construction Scaffold metal plank shines—consistent grip, predictable load behavior, and fewer surprises on wet mornings.

Industry trends

Markets are nudging toward hot-dipped galvanizing and traceable steel grades (Q195/Q235). In fact, many contractors now request documented zinc thickness and load-testing reports. Surprisingly, lightweight planks with reinforced ribs are replacing some older solid units due to safer handling and lower transport costs.

Technical specifications

| Material | Q195 / Q235 carbon steel |

| Surface | Hot-dipped galvanized (HDG), Zn ≈70–100 μm typical (real-world use may vary) |

| Dimensions | General specs or custom: width ≈210–500 mm, height ≈45–60 mm, length around 1.0–3.9 m |

| Anti-slip | Perforated/embossed top, water-drain slots |

| Load rating | Designed to EN 12811-1 duty classes; sample test: 2.5–3.0 kN point load with deflection ≤ L/200 |

| Certificate | ISO 9001 quality management |

| Origin | 200 meters North Of Huangcheng Village, Anping, Hebei, China |

Process flow and quality

Materials: Q195/Q235 coils → slitting → roll-forming ribs and side hooks → perforation/embossing → end-cap welding → pickling & flux → hot-dip galvanizing (per EN ISO 1461/GB/T 13912) → thickness check → load & deflection test (EN 12811) → packaging. Typical service life: ≈10–15 years outdoors; coastal or abrasive sites may see faster zinc consumption.

QC snapshots: Zn thickness sampling; salt-spray benchmarking (ASTM B117, indicative), weld macro-checks, dimensional tolerances, skid-resistance checks when wet.

Applications and advantages

Used in building façades, industrial maintenance, shipyards, petrochem turnarounds, and event staging. Advantages: robust footing, fast placement, reduced slip risk, and easier inspection than timber. Customers say handling weight feels “balanced,” which, I guess, reduces end-of-day fatigue.

Vendor comparison (summary)

| Item | XZ Metal | Vendor B | Vendor C |

| Steel grade traceability | Heat-number logs | Basic mill certs | Occasional |

| Galvanizing thickness | Report each lot (≈80–100 μm) | Typical 60–80 μm | Not always stated |

| Certifications | ISO 9001 | ISO 9001 (pending) | — |

| Lead time | ≈15–25 days | ≈25–35 days | Varies |

Customization

Widths, hook types, anti-slip pattern density, drain slot geometry, and custom branding are available. Third-party tests (around EN 12811) can be arranged on request.

Case studies

1) Petrochem shutdown, Gulf region: 2,300 pcs Galvanized construction Scaffold metal plank, average Zn ≈92 μm; post-6-month inspection showed no red rust, deflection remained within initial spec.

2) High-rise façade, EU: mixed duty classes; planks passed 3.0 kN spot tests with L/230 deflection, crew reported “grippy even after light rain.”

Safety and compliance

Designed with EN 12811-1 in mind; OSHA 1926 Subpart L guidelines considered for U.S. use. Always verify with local codes and competent person inspections.

Authoritative citations

- EN 12811-1/2: Temporary works equipment — Scaffolds.

- EN ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- GB/T 13912: Hot-dip galvanized coatings on steel products (China).

- ASTM A123/A123M: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- OSHA 29 CFR 1926 Subpart L: Scaffolds.

- ISO 9001: Quality management systems — Requirements.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025