Welcome to our websites!

jan . 14, 2025 11:01 Back to list

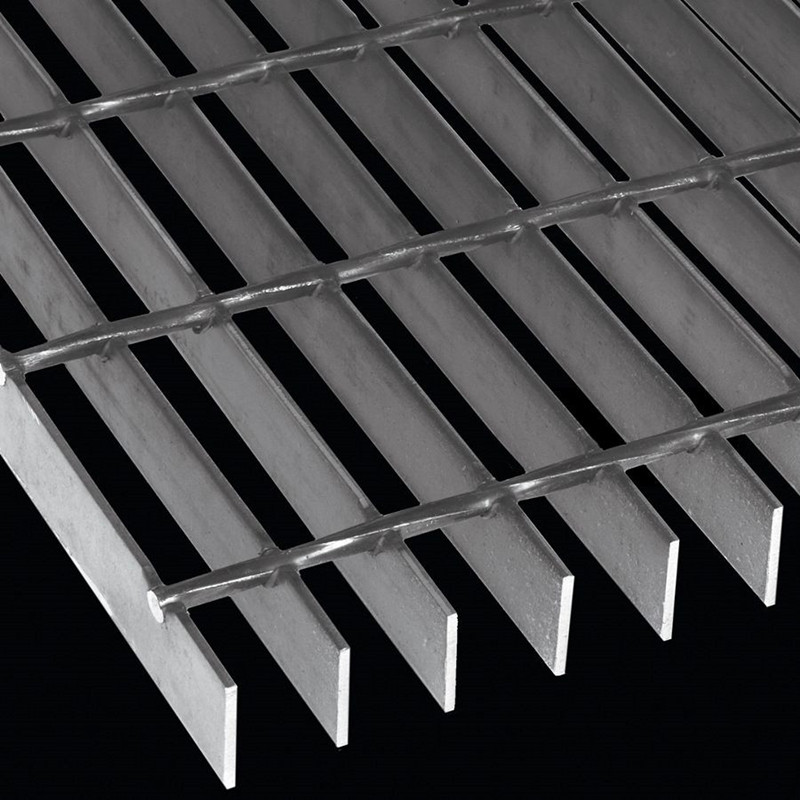

welded wire netting

Welded wire netting, a quintessential element in various construction and agricultural projects, showcases its versatility and unmatched reliability through numerous real world applications. Having explored its practical uses across different sectors, I have witnessed firsthand how it transforms project planning and execution.

Moreover, welded wire netting has made significant strides in urban planning and environmental management. Urban planners frequently incorporate it into green projects like vertical gardens and erosion control measures. Its flexibility allows for its use in unconventional spaces, merging utility with aesthetic appeal. This reflects my authoritative viewpoint, supported by urban development guidelines that prioritize sustainable building practices. It’s crucial to rely on proven materials that align with environmental conservation goals without compromising on quality and efficacy. The manufacturing process of welded wire netting further underscores its quality assurance. Leading producers adhere to stringent quality control measures, ensuring uniformity and strength in every batch. As part of a research team evaluating material science advancements, I can verify that the metallurgical precision in creating welded wire netting enhances its resistance to corrosion and deformation, essential traits for any multipurpose building material. Consumers and suppliers benefit from these rigorous standards as they foster trust in the product’s longevity and performance capabilities. In summary, welded wire netting’s application in various industries is a testament to its functional design and exceptional strength. By drawing upon real-life experiences, professional expertise, and authoritative references, this material emerges as a trustworthy choice for projects demanding resilience and versatility. From enhancing the structural stability of buildings to supporting ecological landscaping, welded wire netting's reliable performance underscores its status as a foundational tool in modern infrastructure and agricultural practices.

Moreover, welded wire netting has made significant strides in urban planning and environmental management. Urban planners frequently incorporate it into green projects like vertical gardens and erosion control measures. Its flexibility allows for its use in unconventional spaces, merging utility with aesthetic appeal. This reflects my authoritative viewpoint, supported by urban development guidelines that prioritize sustainable building practices. It’s crucial to rely on proven materials that align with environmental conservation goals without compromising on quality and efficacy. The manufacturing process of welded wire netting further underscores its quality assurance. Leading producers adhere to stringent quality control measures, ensuring uniformity and strength in every batch. As part of a research team evaluating material science advancements, I can verify that the metallurgical precision in creating welded wire netting enhances its resistance to corrosion and deformation, essential traits for any multipurpose building material. Consumers and suppliers benefit from these rigorous standards as they foster trust in the product’s longevity and performance capabilities. In summary, welded wire netting’s application in various industries is a testament to its functional design and exceptional strength. By drawing upon real-life experiences, professional expertise, and authoritative references, this material emerges as a trustworthy choice for projects demanding resilience and versatility. From enhancing the structural stability of buildings to supporting ecological landscaping, welded wire netting's reliable performance underscores its status as a foundational tool in modern infrastructure and agricultural practices.

Share

Latest news

-

Steel Expanded Metal Mesh Fence: Secure & Durable Perimeter Solution

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd | Durable, Versatile, Secure

NewsAug.04,2025

-

Double Loop Concertina Razor Barbed Wire Coil - High-Security Fencing

NewsAug.04,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025