Oct . 14, 2025 08:05 Back to list

Galvanized/PVC Coated Expanded Metal Mesh Roll/Sheet | Bulk

Field Notes on Galvanized/PVC Coated Expanded Metal Mesh: What Buyers Are Really Asking

I’ve spent enough time in Anping—specifically, 200 meters north of Huangcheng Village in Hebei—to know when a mesh is made right. If you’re evaluating Galvanized/PVC Coated Expanded Metal Mesh Roll/Sheet, a few practical truths keep popping up on job sites: consistency of expansion, coating adhesion, and realistic lead times. The market is active; construction and industrial safety are still driving demand, and architects, funnily enough, love the visual texture.

Technical Overview (and why it matters)

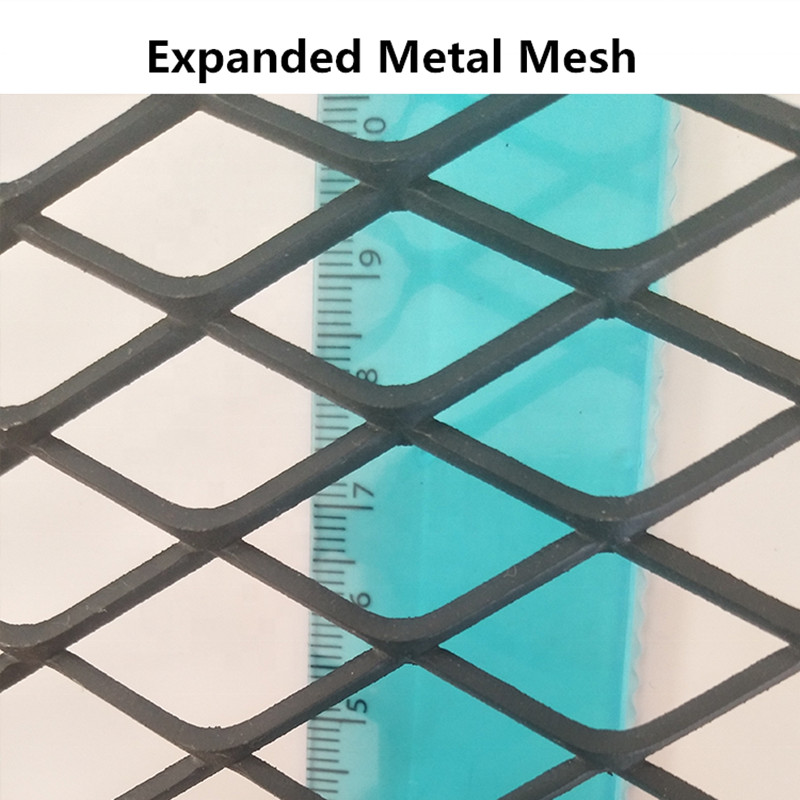

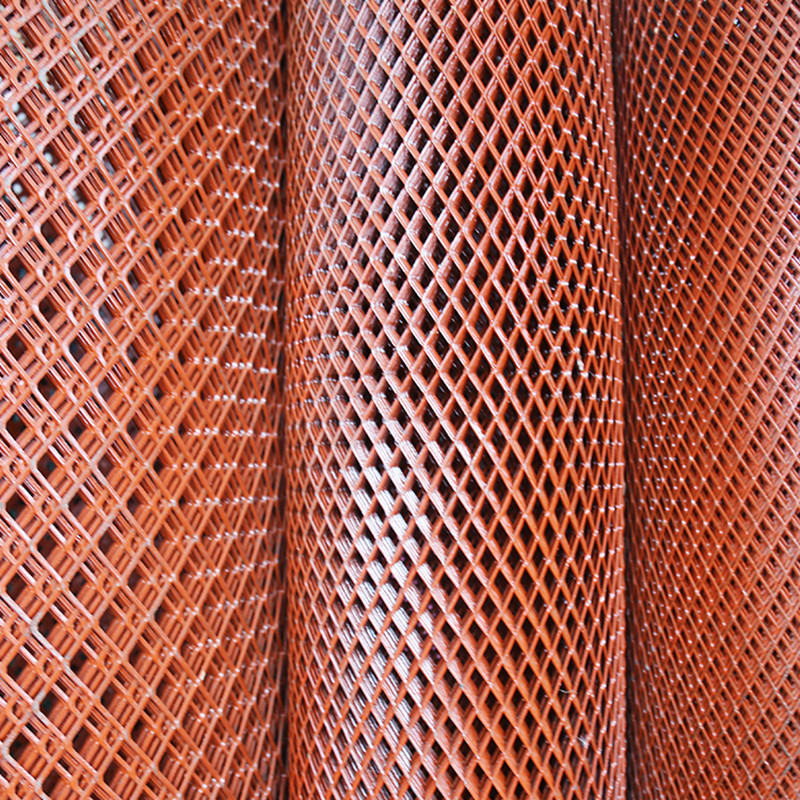

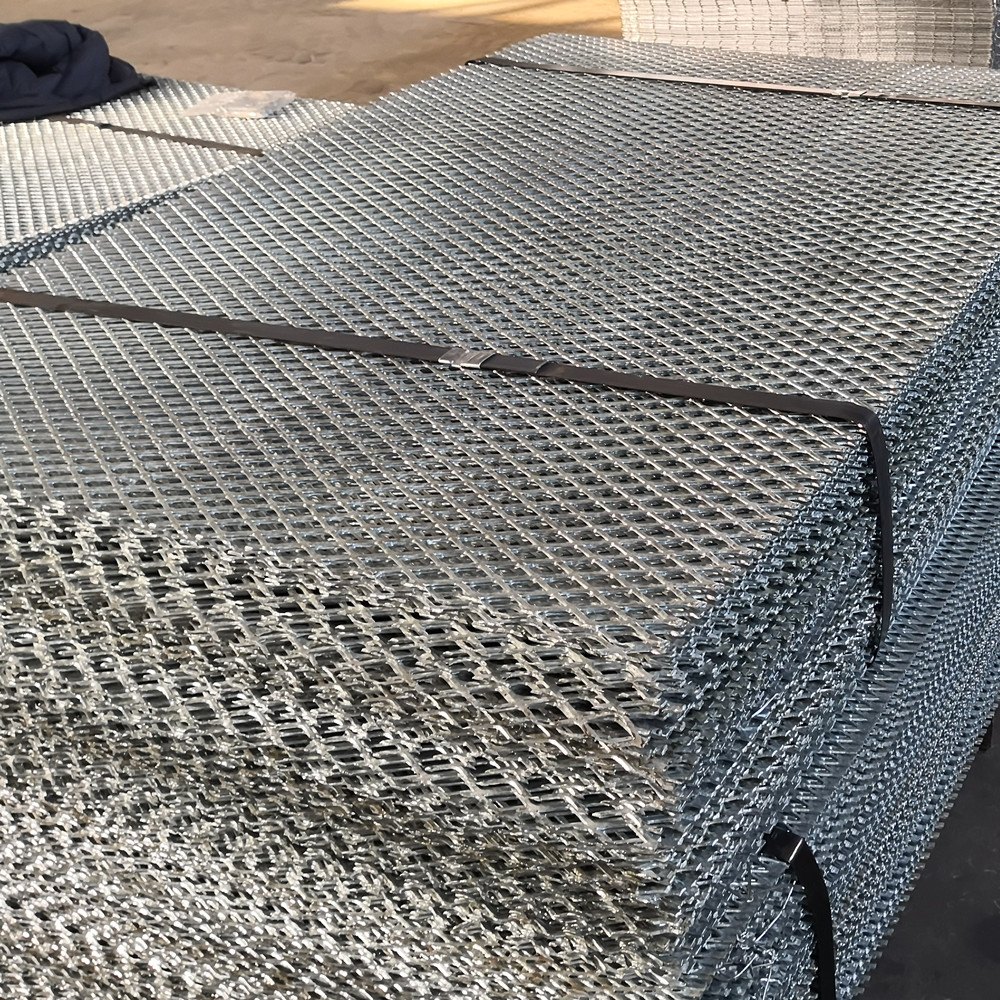

Base steel is typically Q195 or Q235, slit and expanded into diamonds (LWD/SWD). Finishes vary: bare steel for interiors, hot-dip galvanizing for rugged duty, or PVC coating when you want color, noise damping, and extra corrosion security. Many customers say PVC feels “quieter” in pedestrian guard applications. Service life in urban environments? Around 10–20 years galvanized; PVC-coated can stretch further if the coating is properly spec’d and maintained.

| Parameter | Typical Range (≈, real-world use may vary) |

|---|---|

| Material | Q195 / Q235; optional stainless on request |

| LWD × SWD | 12×6 mm to 100×50 mm; custom sizes available |

| Strand Thickness | 0.5–4.0 mm |

| Roll/Sheet Size | Roll width 0.6–2.0 m; sheet up to 2.4×6 m |

| Galvanizing | ISO 1461 hot-dip; zinc ≈ 275–600 g/m² depending on spec |

| PVC Coating | ≈ 200–600 μm; RAL colors; adhesion ISO 2409/ASTM D3359 |

| Open Area | ≈ 35–80% |

| Certificates | ISO, SGS |

Process Flow (what good factories actually do)

- Material prep: Q195/Q235 coils checked for chemistry and thickness tolerance.

- Slitting & expanding: diamond pattern forms in one pass per ASTM F1267.

- Flattening/leveling: to tame camber and keep frames square during install.

- Surface prep: pickling/cleaning; blast as needed.

- Finishing: hot-dip galvanizing (ISO 1461) or PVC coating with oven cure.

- QC & testing: coating thickness, adhesion (ISO 2409/ASTM D3359), salt spray (ISO 9227/ASTM B117), dimensional checks.

Test snapshots: 480–1000 h neutral salt spray is common; field corrosion can vary widely with coastal pollutants—honestly, nothing replaces local experience.

Where it’s used (and why):

Screens, façades, machine guards, doors, ceilings, fencing, catwalks, vent covers—the usual suspects. Architects go for the shadow play; safety managers like the strength-to-weight ratio; installers appreciate that it cuts and fits without unraveling strands.

Vendor Reality Check

| Vendor | Lead Time | MOQ | QC & Tests | Notes |

|---|---|---|---|---|

| XZ Metal (Anping) | ≈ 7–15 days | Around 200–500 m² | ISO 1461, ISO 9227, ISO 2409 reports on request | Origin: China; stable coil sourcing; SGS support |

| OEM A | 10–20 days | ≈ 500 m² | Basic COA; salt-spray optional | Limited RAL palette |

| Trading House B | 15–30 days | Varies | Mixed documentation | Price-driven; specs can drift |

Customization

Custom LWD/SWD, framed panels, CNC-trimmed curves, anti-climb geometry, heavy zinc, and thick PVC are all doable. For coastal jobs, I’d spec Galvanized/PVC Coated Expanded Metal Mesh Roll/Sheet with hot-dip galvanizing plus ≥ 300 μm PVC topcoat and documented salt-spray testing.

Quick Case Notes

- Transit hub façade: 3 mm strand, 62% open area, powder-gray PVC; installers praised consistent flatness.

- Food plant guards: galvanized only; maintenance reported “no flaking” after two winters—small win, but meaningful.

- School fencing: PVC green, anti-climb mesh; parents liked the visibility yet secure feel.

In short, when you’re comparing Galvanized/PVC Coated Expanded Metal Mesh Roll/Sheet, don’t just shop on price. Ask for coating thickness proofs, adhesion data, and real salt-spray hours. It seems basic—yet surprisingly, it’s where projects are won or lost.

Authoritative references

- ASTM F1267 – Standard Specification for Expanded Metals.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles.

- ISO 9227 / ASTM B117 – Neutral salt spray testing methods.

- ISO 2409 / ASTM D3359 – Paints and varnishes, cross-cut adhesion tests.

- ISO 9001 – Quality management systems requirements.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025