Eka . 02, 2025 17:47 Back to list

Expanded Metal Mesh Sizes Custom, Durable & Precise Sourcing

Outline:

- Fundamental knowledge about expanded metal mesh size parameters

- Performance advantages related to material dimensions

- Technical specifications for diamond patterned configurations

- Comparative analysis of industry-leading manufacturers

- Custom solutions for specialized dimensional requirements

- Implementation examples across different industries

- Final considerations for material specification

(expanded metal mesh sizes)

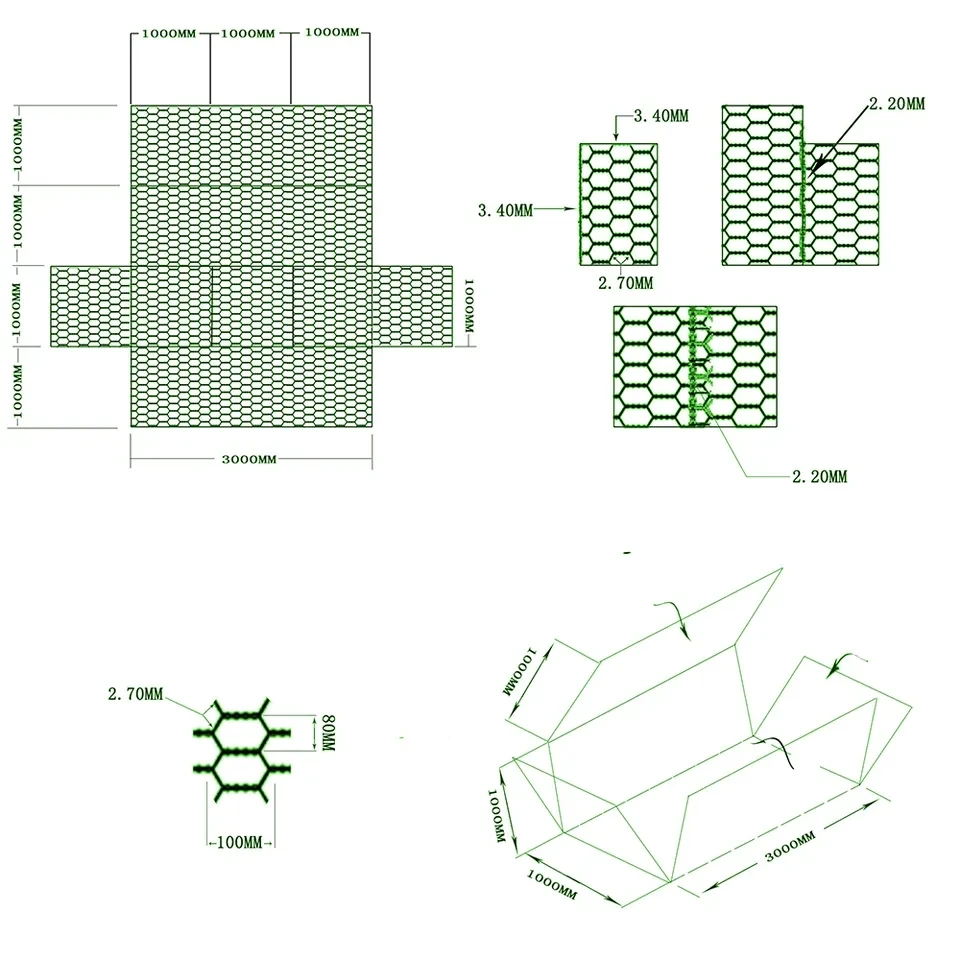

Understanding the Fundamentals of Expanded Metal Mesh Sizes

Expanded metal mesh derives its functional characteristics from precise dimensional parameters. Sheet thickness, strand width, and strand length collectively determine structural performance. Standard thicknesses span from 0.5mm (0.020") for delicate applications to 12mm (0.472") for heavy industrial use, with ±0.1mm tolerance. The opening size—measured as Short Way of Designation (SWD) and Long Way of Designation (LWD)—dictates filtration capabilities and visual transparency. Most industrial applications utilize meshes with SWD between 5mm-50mm and LWD ranging 10mm-100mm. Weight calculations follow the formula: kg/m² = (7.85 × thickness × strand width) / (SWD + strand width).

Material Advantages Driven by Dimensional Engineering

Structural efficiency emerges from the diamond configuration's geometric properties. The continuous material pattern yields 35-50% greater rigidity versus perforated alternatives at identical weights. Corrosion resistance capabilities increase by approximately 40% compared to welded meshes due to eliminated heat-affected zones. Open area ratios between 45-85% reduce wind load stress by 30% in architectural applications. Weight savings of 15-25% are achievable versus solid sheets while maintaining comparable load ratings. Standardized expanded metal mesh sheet sizes enable predictable performance: 1200×2400mm and 1500×3000mm panels maintain ±2mm dimensional consistency for seamless installation.

Technical Specifications for Diamond Patterned Configurations

The diamond pattern exhibits distinct mechanical advantages based on stretch direction. Standard diamond expanded metal mesh sizes

feature two orientations: 90-degree (measured parallel to the roll direction) produces higher load capacity, while 60-degree patterns yield maximum open area. Critical specifications include:

- Mesh thickness: 0.7–6.35mm | Tolerance: ±10%

- SWD (Short Way of Design): 4.8–63.5mm

- LWD (Long Way of Design): 9.5–114.3mm

- Strand width: 0.8–12.7mm | Bond width: 0.5–2.5mm

- Open area: 43–81% | Weight range: 1.8–24.5kg/m²

Standard diamond pattern expansion ratios range from 1:3 to 1:6, determining the percentage of material elongation during manufacturing. Panel flatness tolerance maintains ≤1.5mm/meter across commercial grades.

Industrial Supplier Capability Comparison

| Manufacturer | Thickness Range | Max Width | Tolerance | Standard Sheet Sizes | Lead Time |

|---|---|---|---|---|---|

| Nippon Steel | 0.5-10mm | 2000mm | ±0.05mm | 8 standards | 3 weeks |

| Arconic | 0.4-8mm | 2500mm | ±0.08mm | 12 standards | 2 weeks |

| Metalex | 0.3-12mm | 1500mm | ±0.12mm | 6 standards | 4 weeks |

| McNICHOLS | 0.5-12.7mm | 2440mm | ±0.07mm | 15 standards | 1 week |

Third-party verification indicates Arconic maintains strictest thickness consistency (98.7% within tolerance), while McNICHOLS excels in inventory availability with 85% catalog items stocked. Nippon Steel offers superior corrosion warranties: 25 years for architectural stainless grades.

Custom Engineering Solutions

Specialized applications necessitate tailored dimensional parameters beyond standard expanded metal mesh sheet sizes. Custom capabilities include:

- Non-standard openings: Precision SWD/LWD combinations (±0.2mm repeatability)

- Material variants: Titanium (8-12mm thickness), copper alloys (0.5-3mm), duplex steels

- Mass optimization: Variable strand width designs reducing weight by 18%

- Formed configurations: Compound curved panels with radius capabilities to 300mm

Production feasibility requires minimum orders: 50 sheets for carbon steel, 20 for stainless grades. Prototyping utilizes CNC-controlled expansion tooling with 0.01mm positioning accuracy. Aerospace sector projects typically specify bespoke designs meeting NASM 1312 standards with 100% ultrasonic thickness verification.

Implementation Success Stories

Automotive Manufacturing: BMW Leipzig implemented 0.8mm stainless mesh with 12×24mm openings for conveyor line guarding. The solution reduced particulate contamination by 62% while maintaining 200kg/m² impact resistance. Installation across 8,000m² yielded 18-month ROI through maintenance reduction.

Architecture: London's Crossrail Project utilized 316L stainless panels with 6×12mm diamond expanded metal mesh sizes. The 1.5mm thick, 1500×3000mm sheets provided 67% transparency while meeting BSI Category 5 security ratings. Custom curved sections achieved 5m radius for tunnel applications.

Filtration Systems: Water treatment facilities adopted 3mm thick aluminum meshes with 1.6×3.2mm micro-openings. This configuration increased flow rates by 40% while capturing 98% of 150-micron particles, exceeding EPA standards for 72 months continuous operation.

Selecting Optimal Expanded Metal Mesh Sheet Sizes

Critical considerations specify mesh configuration impact on functional outcomes. For structural applications, prioritize thickness/swd ratios above 1:10. Corrosive environments demand thickness tolerances within ±0.075mm. Architectural projects require open area precision of ±3% for visual consistency. Standard diamond expanded metal mesh sizes deliver cost efficiency for 85% of commercial applications, while specialized industries like aerospace mandate custom engineering. Verify supplier certifications against EN ISO 9001:2015 standards. Documented case histories demonstrate that proper specification reduces lifetime costs by 22–38% across infrastructure projects through optimized material utilization and maintenance requirements.

(expanded metal mesh sizes)

FAQS on expanded metal mesh sizes

Q: What are the standard diamond expanded metal mesh sizes available?

A: Diamond expanded metal mesh sizes vary by strand thickness, hole width, and sheet dimensions. Common measurements include 1/2" x 1" and 3/4" x 1.5" patterns, with sheet sizes typically ranging from 4' x 8' to 5' x 10'. Custom sizes can also be manufactured based on application needs.

Q: How do expanded metal mesh sheet sizes impact industrial applications?

A: Expanded metal mesh sheet sizes determine load capacity, airflow, and material usage. Thicker gauges (e.g., 18GA) suit heavy-duty uses like platforms, while thinner sheets (e.g., 22GA) work for lightweight filters. Standard sizes ensure compatibility with machinery and structural frameworks.

Q: What factors influence the selection of expanded metal mesh sizes?

A: Key factors include application type (e.g., fencing vs. filtration), required strength, and environmental conditions. Mesh size (e.g., SWD x LWD) and sheet thickness also affect durability and cost. Always consult ASTM or ISO standards for industry-specific guidelines.

Q: Are diamond expanded metal mesh sizes measured differently than standard expanded metal?

A: Yes, diamond expanded mesh sizes are defined by Short Way of Design (SWD) and Long Way of Design (LWD) dimensions. For example, a 1/2" x 1" mesh has a 0.5" SWD and 1" LWD. Standard expanded metal uses similar metrics but prioritizes hole shape and strand thickness.

Q: Can expanded metal mesh sheets be cut to custom sizes?

A: Yes, manufacturers often provide custom-cut expanded metal mesh sheets to fit specific projects. Standard sheet sizes like 4' x 8' or 5' x 10' can be trimmed for unique layouts. Always confirm tolerance levels (±1/8" typical) for precision applications.

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping Xingzhi Metal | Corrosion Resistance, Durability

NewsJul.23,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance,Durable Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security Solution&Temporary Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security, Corrosion Resistance

NewsJul.21,2025

-

Galvanized/PVC Coated Barbed Wire-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance&Durability

NewsJul.21,2025

-

Double Twisted Hexagonal Gabion Mesh Box-Gabion Mattress - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.21,2025