Aug . 11, 2025 00:20 Back to list

Hot Dipped Galvanized Steel Grating | Durable Bar Grating Solutions

The Indispensable Role of Hot Dipped Galvanized Steel Grating in Modern Industrial Infrastructure

In the realm of modern industrial and commercial infrastructure, the demand for robust, durable, and corrosion-resistant materials is paramount. Among these, Hot Dipped Galvanized Steel Grating/Bar Grating stands out as a foundational component, widely recognized for its unparalleled strength-to-weight ratio and exceptional longevity in harsh environments. This versatile material, primarily utilized for platforms, walkways, stair treads, and drainage covers, serves as a critical enabler for operational safety and efficiency across a myriad of sectors. Its intrinsic properties, born from a meticulously controlled manufacturing and galvanization process, ensure resilience against corrosive elements, heavy loads, and abrasive conditions, making it an economically viable and structurally superior choice for long-term investments. The current industrial landscape is increasingly focused on sustainability, extended asset lifecycles, and minimal maintenance, all of which are inherently supported by the deployment of high-quality hot-dipped galvanized steel gratings. The growing emphasis on stringent safety regulations in industrial facilities further bolsters the adoption of such reliable materials, mitigating risks associated with structural integrity failures and ensuring a secure working environment for personnel. Furthermore, advancements in design and fabrication technologies allow for highly customized grating solutions, adapting to complex architectural and engineering specifications, thereby expanding its application scope beyond traditional industrial uses into innovative urban and commercial designs, including aesthetically pleasing façades and sunshades.

The industry's trajectory indicates a sustained growth in the demand for engineered grating solutions, driven by global infrastructure development, renewal projects, and the expansion of industrial capacities. Key trends highlight a shift towards solutions that offer superior life-cycle costing, where initial investment is offset by reduced maintenance and replacement frequencies. Digital transformation, though seemingly distant from a physical product like steel grating, impacts the sector through advanced design software, precision manufacturing, and streamlined supply chain management, leading to more efficient production and delivery of tailored solutions. The commitment to environmental stewardship also plays a role, with manufacturers increasingly adopting eco-friendly processes and materials, minimizing waste, and ensuring the recyclability of end-of-life products. This commitment extends to optimizing energy consumption during the manufacturing process, particularly in the hot-dip galvanization stage, which is crucial for achieving the desired anti-corrosion properties. The architectural design community is also recognizing the aesthetic potential of exposed steel grating, integrating it into contemporary designs for its utilitarian beauty, transparency, and ventilation properties, particularly in public spaces and commercial complexes where both form and function are equally valued. This dual appeal, combining robust industrial utility with modern design flexibility, ensures the continued relevance and expansion of Hot Dipped Galvanized Steel Grating/Bar Grating in both traditional and emerging markets.

Understanding the Core: Structure and Galvanization of Steel Grating

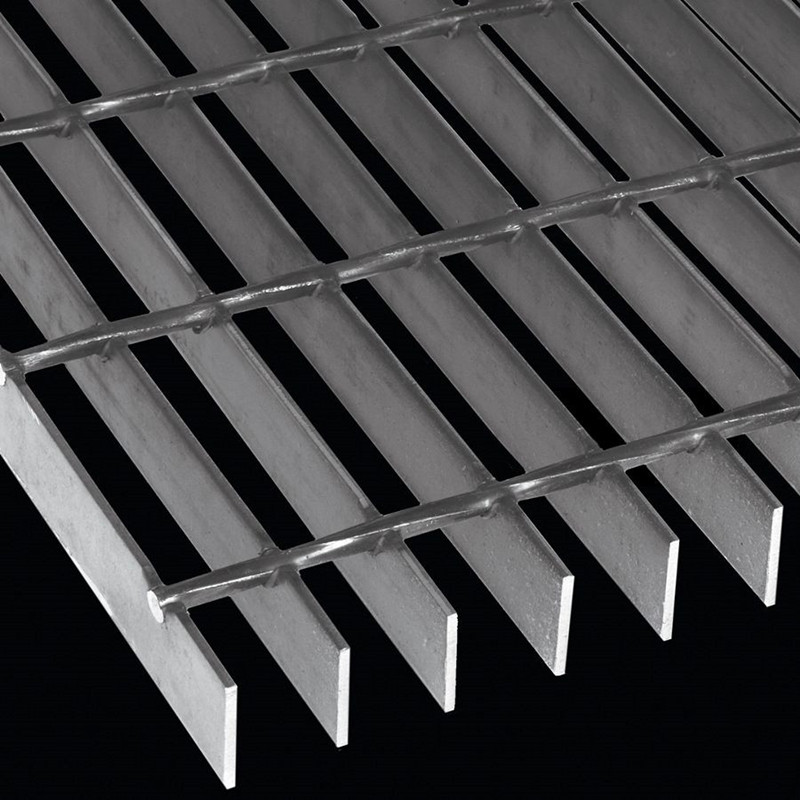

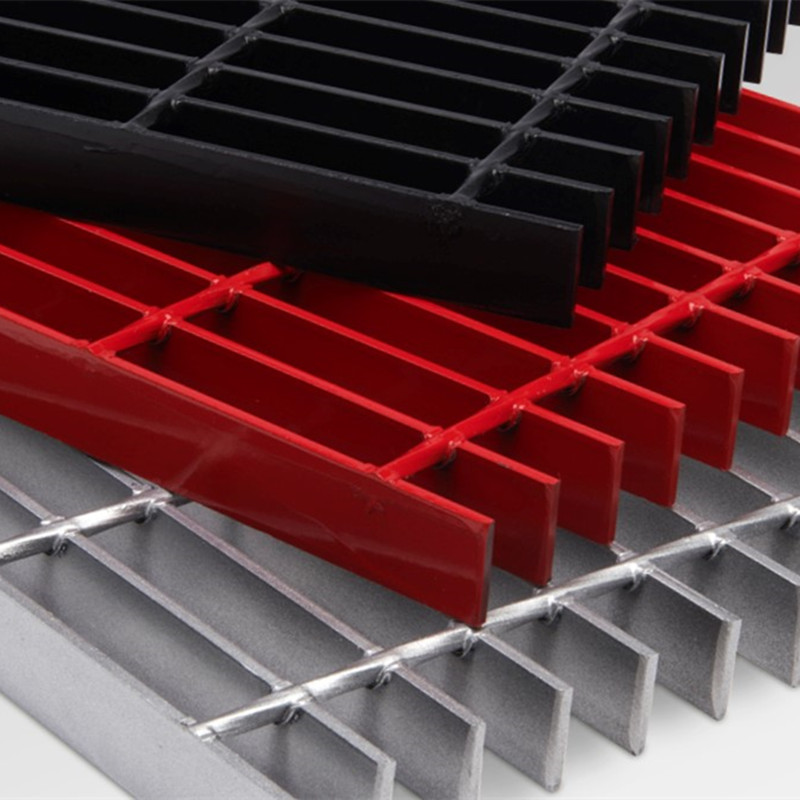

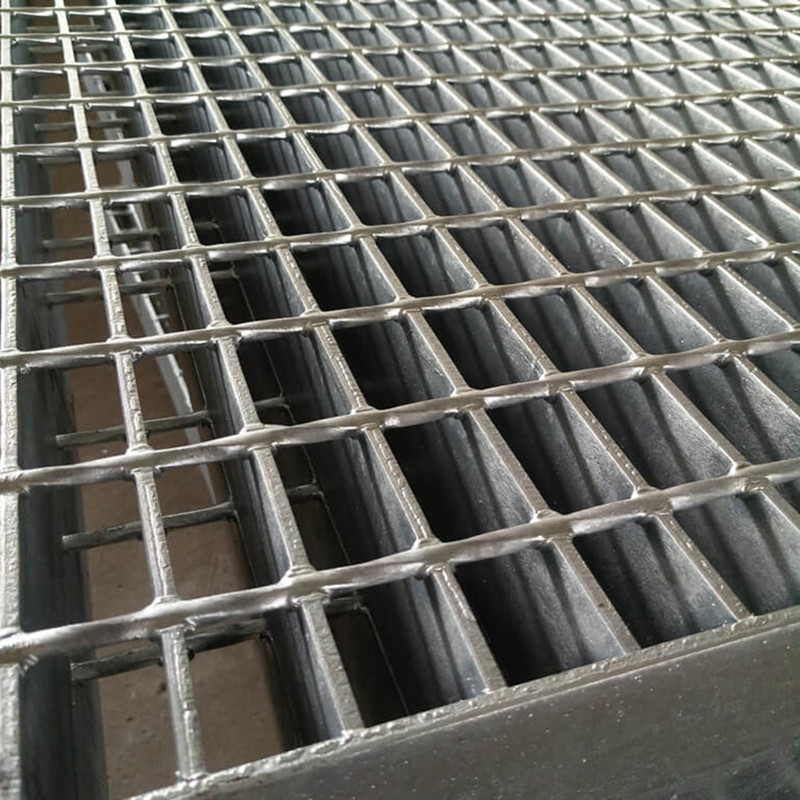

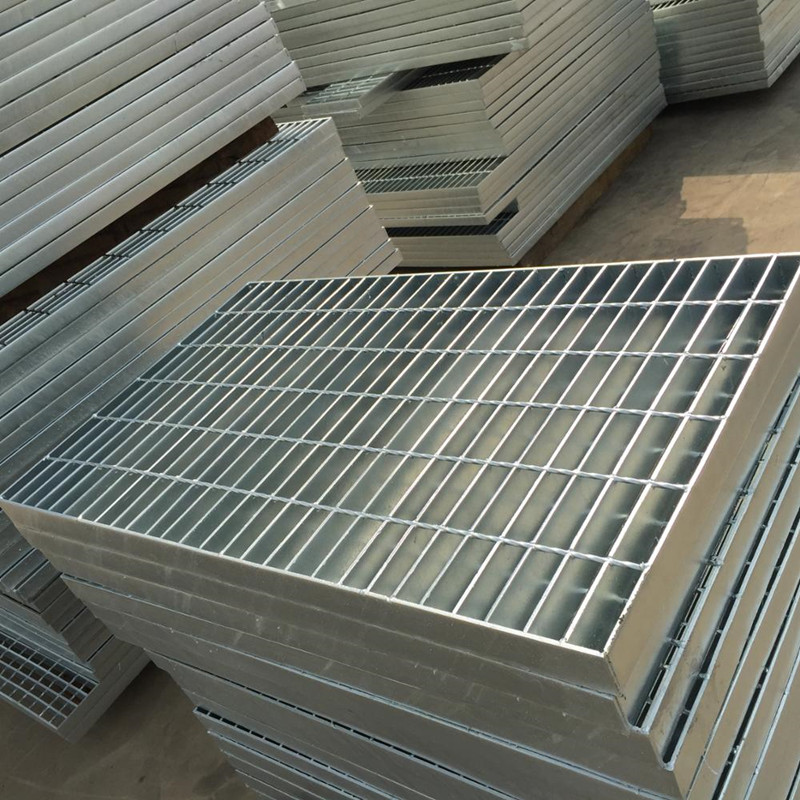

At its essence, Hot Dipped Galvanized Steel Grating/Bar Grating is a structural assembly comprising a series of bearing bars, typically flat steel strips, oriented vertically and spaced parallel to each other. These bearing bars bear the primary load. Intersecting them are cross bars, which can be round rods, twisted square bars, or flat bars, permanently joined to the bearing bars to form a rigid, load-distributing panel. The method of joining these elements defines the grating type: welded steel grating, pressure-locked grating, or swage-locked grating. Welded grating, the most common type, involves resistance welding the cross bars to the bearing bars, ensuring a strong and durable joint. Pressure-locked grating utilizes extreme hydraulic pressure to force the cross bars into pre-notched bearing bars, creating a tight, interlocking mechanical bond, often preferred for its clean appearance. Swage-locked grating uses swaging to deform the cross bars into the bearing bars, offering high load-bearing capacity and a secure connection. The choice between these types often depends on the specific application's load requirements, aesthetic considerations, and environmental factors. The integrity of this grid structure provides excellent ventilation, light penetration, and drainage capabilities, making it ideal for elevated walkways, platforms, and trench covers where these properties are essential for safety and operational efficiency, especially in environments where spillage or debris accumulation is a concern, as the open mesh design prevents the build-up of hazards.

The transformative "Hot Dipped Galvanized" process is what elevates ordinary steel grating to its superior corrosion-resistant status. After fabrication, the steel grating is thoroughly cleaned through a multi-stage process involving degreasing, acid pickling to remove mill scale and rust, and fluxing to prepare the surface for bonding. This meticulous preparation is critical for the success of the galvanization. The clean steel is then immersed in a bath of molten zinc, maintained at a temperature of approximately 450°C (840°F). During this immersion, a metallurgical reaction occurs between the iron in the steel and the molten zinc, forming a series of zinc-iron alloy layers on the steel surface, topped by a pure zinc layer. This multi-layered coating is metallurgically bonded to the steel, providing a barrier protection that is significantly more durable and adherent than paint or other surface coatings. Unlike a simple coating, any minor scratch or abrasion that penetrates the pure zinc layer will still be protected by the underlying alloy layers, and even if the steel is exposed, the surrounding zinc acts as a sacrificial anode, corroding preferentially to protect the steel (cathodic protection). This unique combination of barrier and cathodic protection ensures exceptional longevity and resistance to rust and corrosion, even in highly aggressive industrial atmospheres or marine environments, making Hot Dipped Galvanized Steel Grating/Bar Grating a highly preferred material for infrastructure components exposed to severe weather conditions or chemical exposure, guaranteeing a much longer service life compared to untreated or painted steel.

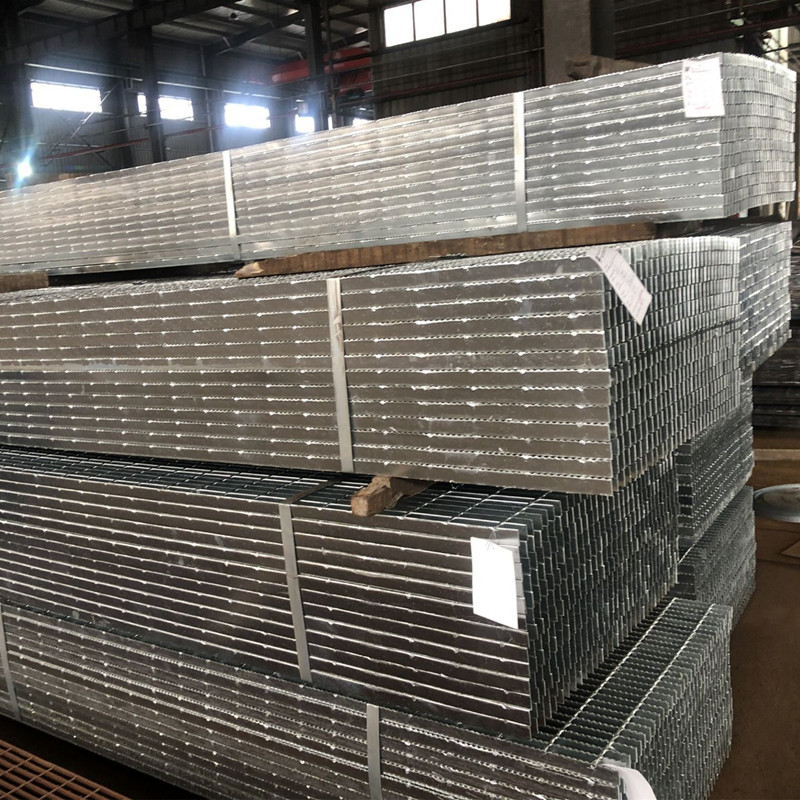

The Meticulous Manufacturing Process of Hot Dipped Galvanized Steel Grating

The production of high-quality Hot Dipped Galvanized Steel Grating/Bar Grating is a sophisticated process involving several critical stages, each governed by stringent quality control measures to ensure the final product meets exacting industry standards like ISO 9001, ASTM A123, ISO 1461, and ANSI/NAAMM MBG 531. The journey begins with the selection of raw materials, primarily high-grade carbon steel (e.g., ASTM A36, Q235, S275JR) chosen for its strength and weldability. These steel coils or plates are then precisely cut into bearing bars and cross bars according to specified dimensions using advanced shearing or laser cutting machinery, ensuring accuracy and minimal material waste. The subsequent fabrication method depends on the grating type: for welded gratings, bearing bars are notched, and cross bars are resistance-welded to them under immense pressure and heat, creating robust, permanent joints. For pressure-locked or swage-locked gratings, specialized machines mechanically interlock the bars, achieving a tight, secure fit without welding. After the main grating panels are formed, edge banding, often using flat bar or angle iron, is welded around the perimeter to provide additional structural integrity, prevent distortion, and enhance aesthetic appeal. This entire fabrication phase is crucial for ensuring the structural integrity and dimensional accuracy of the grating panels before they proceed to the galvanization stage, requiring precision tooling and skilled operators to maintain tight tolerances for all components, which directly impacts the ease of installation and overall performance in the field.

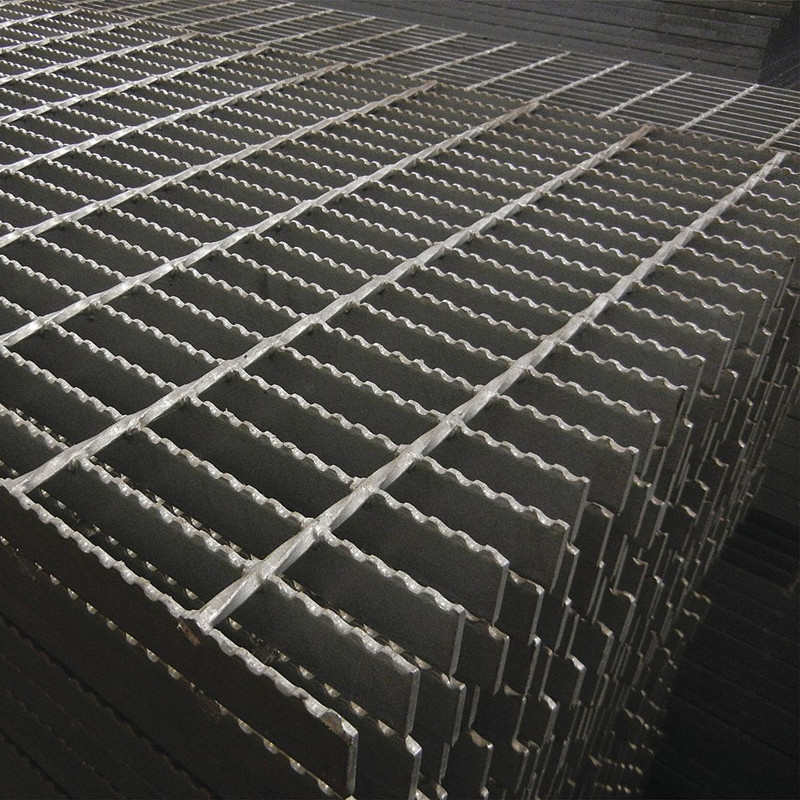

The galvanizing process, the cornerstone of the product's superior corrosion resistance, starts with meticulous surface preparation. Grating panels undergo a multi-stage cleaning protocol: first, degreasing to remove oils and grease; then, acid pickling (hydrochloric or sulfuric acid) to strip off rust and mill scale, exposing a clean, reactive steel surface. This is followed by a rinse and then immersion in a flux solution (typically zinc ammonium chloride) to prevent oxidation before dipping and to promote the metallurgical reaction. The prepared gratings are then immersed into a bath of molten zinc at approximately 450°C (840°F). At this temperature, the iron in the steel reacts with the molten zinc to form a series of distinct zinc-iron alloy layers (gamma, delta, zeta, and eta), chemically bonded to the steel substrate, culminating in an outer layer of pure zinc. This diffusion process continues until the grating reaches the temperature of the molten zinc. Upon withdrawal, excess zinc drains off, and the grating is allowed to cool, often by air or water quenching. The thickness of the zinc coating, typically measured in microns, is a critical parameter that directly influences the grating's service life and is meticulously controlled and measured post-galvanization to comply with standards like ASTM A123/A123M or ISO 1461. Rigorous post-galvanization inspection includes visual checks for uniformity, adherence, and coverage, as well as destructive and non-destructive testing for coating thickness, ensuring that every panel of Hot Dipped Galvanized Steel Grating/Bar Grating meets the specified corrosion protection requirements before it is dispatched for packaging and delivery.

Key Technical Parameters and Specifications of Hot Dipped Galvanized Steel Grating

Understanding the technical parameters of Hot Dipped Galvanized Steel Grating/Bar Grating is crucial for specifying the correct product for a given application, ensuring both structural integrity and optimal performance. These parameters dictate the grating's load-bearing capacity, slip resistance, drainage capabilities, and overall suitability for diverse industrial environments. The primary specifications include the dimensions of the bearing bars (depth and thickness), their spacing, the type and spacing of cross bars, the material grade, and the surface finish. Bearing bar depth and thickness are the most critical factors determining the grating's ability to withstand loads; deeper and thicker bars offer higher load capacity and deflection resistance. Common bearing bar depths range from 20mm to 100mm, with thicknesses typically from 3mm to 10mm. Bearing bar spacing (pitch), which refers to the center-to-center distance between adjacent bearing bars, commonly ranges from 20mm to 60mm, with tighter spacing providing better support for smaller objects and enhanced pedestrian comfort, albeit with higher material cost and reduced light/air penetration. Cross bar spacing, usually between 50mm and 100mm, ensures rigidity and distributes loads across multiple bearing bars, preventing twisting or buckling, while specific applications might require even tighter spacing to prevent objects from falling through the grating, or wider spacing for improved flow rates in drainage applications.

The surface finish of Hot Dipped Galvanized Steel Grating/Bar Grating is another vital parameter, affecting slip resistance and aesthetics. Options include plain (smooth) or serrated surfaces. Serrated grating, with its notched bearing bars, provides superior slip resistance, making it ideal for wet, oily, or icy conditions prevalent in offshore platforms, chemical plants, or food processing facilities, where worker safety is paramount. While plain grating is suitable for drier indoor environments or where a smoother aesthetic is preferred, the serrated option is almost always chosen for exterior or industrial applications to meet safety standards. The galvanization coating thickness, conforming to standards such as ASTM A123 for general products or ASTM A153 for hardware, directly impacts the grating's corrosion protection and expected service life; a thicker coating provides longer protection in aggressive environments. Material grade, typically low carbon steel like Q235 (Chinese standard), A36 (ASTM), or S275JR (EN standard), ensures the structural strength and ductility required for fabrication and load bearing. Load tables, provided by manufacturers, illustrate the safe working load and maximum deflection for various span lengths and grating configurations, aiding engineers in selecting the appropriate grating for specific design requirements. Consideration of factors like span width, concentrated vs. distributed loads, and dynamic vs. static loads is crucial during the design phase to ensure the grating's structural integrity and compliance with local building codes and safety regulations.

Typical Hot Dipped Galvanized Steel Grating Specifications

| Parameter | Common Range/Value | Industry Standard | Impact on Performance |

|---|---|---|---|

| Bearing Bar Depth | 20mm - 100mm (0.75" - 4") | ANSI/NAAMM MBG 531, YB/T 4001.1 | Primary determinant of load capacity and span capability. |

| Bearing Bar Thickness | 3mm - 10mm (1/8" - 3/8") | ANSI/NAAMM MBG 531, YB/T 4001.1 | Contributes to load capacity and rigidity; thinner bars offer more light/air passage. |

| Bearing Bar Spacing (Pitch) | 30mm, 40mm, 60mm (1-3/16", 1-9/16", 2-3/8") | ANSI/NAAMM MBG 531, YB/T 4001.1 | Affects support for small objects, comfort, light/air flow, and overall cost. |

| Cross Bar Spacing (Pitch) | 50mm, 100mm (2", 4") | ANSI/NAAMM MBG 531, YB/T 4001.1 | Ensures lateral stability and load distribution. |

| Material Grade | Q235 (China), A36 (ASTM), S275JR (EN) | Relevant National/International Steel Standards | Determines base strength, weldability, and structural integrity. |

| Surface Finish | Plain or Serrated | ANSI/NAAMM MBG 531 | Serrated enhances slip resistance, crucial for safety in wet/oily conditions. |

| Galvanization Coating Thickness | ≥ 610 g/m² for elements ≥ 6mm thick | ASTM A123/A123M, ISO 1461 | Directly proportional to corrosion resistance and service life. |

| Panel Dimensions | Customizable (e.g., up to 6m x 1m) | Project Specific | Influences installation efficiency, material handling, and structural layout. |

Unparalleled Advantages and Performance Benefits of Hot Dipped Galvanized Steel Grating

The widespread adoption of Hot Dipped Galvanized Steel Grating/Bar Grating across diverse industries is directly attributable to its remarkable array of advantages and superior performance characteristics, particularly its exceptional corrosion resistance. The hot-dip galvanization process creates a metallurgical bond between the zinc coating and the steel substrate, forming a barrier that is significantly more robust and durable than paint or other surface treatments. This multi-layered zinc-iron alloy and pure zinc coating provides both barrier protection, isolating the steel from the corrosive environment, and cathodic protection, where the zinc preferentially corrodes to protect any exposed steel areas, even if scratched or damaged. This dual defense mechanism ensures an extended service life, often exceeding 50 years in less aggressive environments and 20-25 years even in highly corrosive industrial or marine atmospheres, dramatically reducing the need for costly maintenance, repainting, or premature replacement compared to untreated or conventionally painted steel structures. This longevity translates into substantial long-term cost savings for infrastructure projects, making it a highly economical choice over the entire lifecycle of the asset, contributing to a lower total cost of ownership which is a critical consideration for B2B procurement decisions.

Beyond its corrosion resistance, the inherent properties of steel grating contribute to its high strength-to-weight ratio, allowing it to support significant loads while remaining relatively lightweight, simplifying installation and reducing structural support requirements. Its open mesh design offers superior ventilation, light penetration, and drainage capabilities, critical for safety in industrial settings where gases, liquids, or debris could accumulate. Excellent drainage prevents pooling of water, reducing slip hazards and preventing the accumulation of corrosive substances on the grating surface. The choice between plain and serrated surfaces provides tailored slip resistance, with serrated grating offering enhanced grip in challenging conditions, further bolstering safety. The material's fire-resistant nature, being non-combustible steel, provides an additional layer of safety in high-risk environments. Furthermore, Hot Dipped Galvanized Steel Grating/Bar Grating is virtually maintenance-free once installed, requiring only occasional cleaning, which significantly reduces operational costs and downtime for inspections and repairs. Its robust construction ensures durability against heavy foot traffic, vehicular loads, and industrial equipment, maintaining structural integrity over decades of continuous use. From an environmental perspective, steel is 100% recyclable, and the galvanization process itself is highly sustainable, with zinc being a naturally occurring element, ensuring that the product aligns with modern environmental responsibility initiatives and contributes to green building certifications, adding another layer of value for environmentally conscious businesses.

Diverse Applications Across Key Industries

The versatility and robust performance of Hot Dipped Galvanized Steel Grating/Bar Grating make it an indispensable material across a broad spectrum of industrial and commercial applications. In the petrochemical industry, including refineries, chemical plants, and oil & gas facilities, grating is extensively used for platforms, elevated walkways, stair treads, and trench covers. Its superior corrosion resistance is critical in environments exposed to corrosive chemicals, salt spray, and extreme temperatures, ensuring the safety of personnel accessing elevated equipment and preventing structural degradation. The open design also allows for effective drainage of spills and excellent ventilation, dissipating hazardous fumes and heat, which are paramount for operational safety in these volatile environments. For instance, in a large-scale chemical processing plant, several kilometers of galvanized grating might be deployed across distillation towers, reactor platforms, and pumping stations, reliably supporting heavy equipment and continuous foot traffic while resisting the corrosive effects of acids, alkalis, and hydrocarbons. This extensive application highlights the material's critical role in maintaining operational continuity and worker safety under the most demanding conditions, underscoring its functional indispensability within complex industrial ecosystems.

In the metallurgy and mining sectors, particularly in steel mills, smelting plants, and mineral processing facilities, galvanized steel grating provides durable and safe access solutions for furnace platforms, conveyor walkways, and machinery access points. The material's ability to withstand high temperatures and abrasive conditions, coupled with its resistance to heavy industrial traffic and impact loads, makes it an ideal choice. For example, in a hot rolling mill, workers require secure walkways around furnaces and rolling stands, where temperatures are extreme and molten metal splashes are a risk. The robust nature and anti-corrosive properties of hot-dipped galvanized grating ensure longevity and minimize maintenance in these demanding, high-wear environments. Power generation plants, including thermal, hydroelectric, and nuclear facilities, also rely heavily on Hot Dipped Galvanized Steel Grating/Bar Grating for boiler platforms, turbine halls, switchgear areas, and cable trench covers. The material's non-combustibility and open design contribute to fire safety by preventing accumulation of combustible materials and allowing easy access for maintenance and inspection of critical electrical and mechanical systems. The long lifespan of galvanized grating aligns perfectly with the multi-decade operational cycles of power plants, providing a reliable and cost-effective solution for permanent infrastructure elements.

The water and wastewater treatment industries are significant users of galvanized grating for access platforms around tanks, filtration systems, pump stations, and trench covers. Here, constant exposure to moisture, chemicals, and corrosive gases (like hydrogen sulfide) necessitates materials with superior corrosion resistance. Galvanized grating ensures long-term structural integrity and safety in these continuously wet and chemically active environments. Its open structure facilitates effective drainage, preventing stagnant water and promoting hygienic conditions crucial for plant operation. Beyond heavy industry, Hot Dipped Galvanized Steel Grating/Bar Grating finds application in architectural and commercial projects, including mezzanines, building facades, sunscreens, and decorative elements, where its clean lines, strength, and durability are valued. Public infrastructure, such as bridges, port facilities, and transportation hubs, utilize it for pedestrian walkways, gangways, and service platforms, benefiting from its high load-bearing capacity and resilience to environmental stressors like salt water and heavy foot traffic. The ability to customize dimensions, shapes, and surface finishes further enhances its adaptability across such a wide array of applications, ensuring that designers and engineers can specify a product that perfectly meets both functional requirements and aesthetic aspirations of any given project, from a heavy-duty industrial facility to a modern urban park.

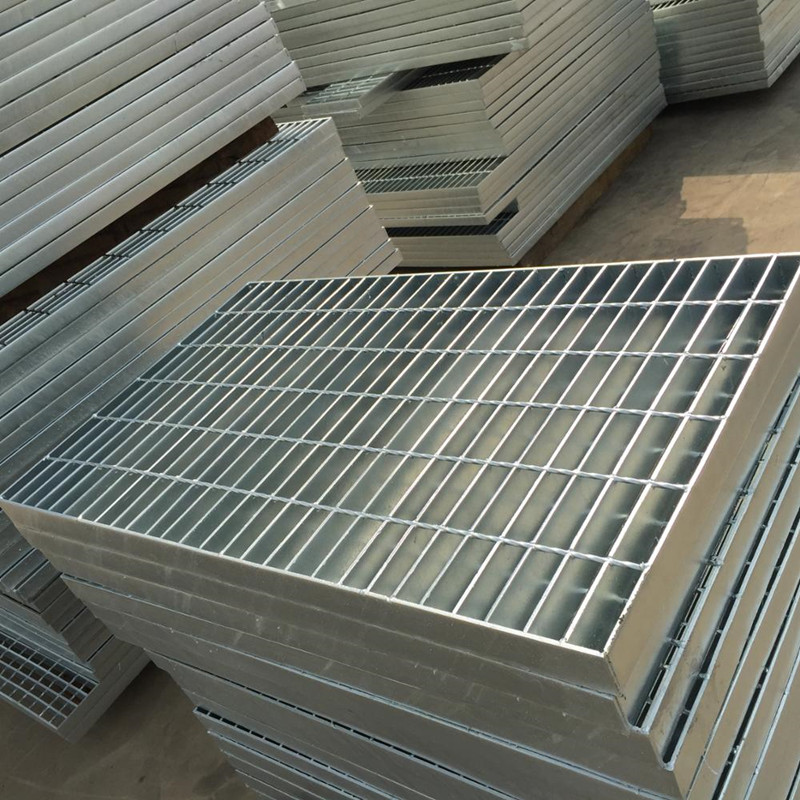

Customization and Solution Design for Specific Project Requirements

While standard sizes of Hot Dipped Galvanized Steel Grating/Bar Grating are readily available, a significant advantage lies in its capacity for extensive customization, allowing manufacturers to provide tailored solutions that precisely fit complex project specifications. This adaptability is crucial for addressing unique structural layouts, load requirements, safety considerations, and aesthetic preferences. Customization options begin with precise dimensions: grating panels can be fabricated to exact lengths, widths, and shapes (e.g., circular, curved, or irregular cut-outs) to accommodate architectural features, pipe penetrations, machinery bases, or column supports. This bespoke fabrication minimizes on-site cutting and welding, reducing installation time, labor costs, and potential for errors or damage to the galvanized coating. Furthermore, the selection of bearing bar depth, thickness, and spacing can be optimized to meet specific live and dead load capacities, ensuring that the grating system is engineered for the precise stresses it will endure, whether for pedestrian traffic, heavy industrial vehicles, or concentrated machinery loads, thus maximizing safety and structural integrity while optimizing material usage.

Beyond basic dimensions, customization extends to specialized features and accessories. This includes the integration of stair treads with nosings (checker plate, abrasive, or defined edge profiles) for enhanced visibility and slip resistance on steps, as well as kick plates (toe plates) welded to the grating perimeter to prevent objects from falling off elevated platforms. Various types of fastening clips (saddle clips, G-clips, M-clips) can be supplied to securely anchor the grating to supporting structures, offering flexibility for different installation scenarios and ease of removal for maintenance access. For unique environments, special surface treatments beyond standard plain or serrated options might be considered, such as highly aggressive abrasive coatings or specific paint systems applied over the galvanization for aesthetic purposes or additional chemical resistance in extremely hostile conditions. Engineering consultation plays a pivotal role in this customization process. Experienced manufacturers leverage advanced CAD/CAM systems and FEA (Finite Element Analysis) software to design, model, and analyze the performance of custom grating configurations under anticipated loads and environmental conditions, ensuring that the final product is not only precisely manufactured but also optimally designed for maximum safety, efficiency, and longevity. This collaborative approach between the client and the manufacturer guarantees that the specified Hot Dipped Galvanized Steel Grating/Bar Grating solution is perfectly aligned with the project's operational demands and safety standards, offering a comprehensive and integrated solution that goes beyond off-the-shelf products.

Choosing the Right Partner: Manufacturer Comparison and Selection Guide

Selecting the appropriate manufacturer for Hot Dipped Galvanized Steel Grating/Bar Grating is a critical decision that significantly impacts project success, safety, and long-term cost-effectiveness. In a competitive market, discerning buyers must evaluate potential suppliers based on several key criteria that go beyond mere price. Foremost among these is adherence to quality certifications and industry standards. A reputable manufacturer will possess certifications like ISO 9001 (Quality Management System), demonstrating a commitment to consistent product quality and process control. Furthermore, their products should conform to international grating standards such as ANSI/NAAMM MBG 531 (USA), BS 4592 (UK), DIN 24537 (Germany), YB/T 4001.1 (China), and especially galvanization standards like ASTM A123/A123M or ISO 1461. Verification of these standards ensures that the grating meets specified load capacities, dimensional tolerances, and corrosion protection levels. A manufacturer's testing capabilities, including in-house load testing, galvanization thickness testing (e.g., using eddy current or magnetic gauges), and visual inspection protocols, provide further assurance of product reliability and compliance with engineering specifications, mitigating risks associated with sub-standard materials that could compromise structural integrity or lead to premature failure in demanding industrial environments, ultimately safeguarding investments and personnel.

Beyond certifications, manufacturing capacity and technological prowess are crucial indicators of a supplier's capability. A manufacturer with state-of-the-art automated welding lines, precision cutting equipment, and efficient galvanizing plants can ensure higher production volumes, consistent quality, and shorter lead times for large-scale projects. Engineering support and customization capabilities are also paramount. A proficient manufacturer should offer comprehensive design assistance, including CAD drawings, load calculations, and the ability to fabricate complex shapes and sizes. Their experience in specific industry applications (e.g., petrochemical, marine, power generation) demonstrates their understanding of unique challenges and regulatory requirements within those sectors. Service history, client testimonials, and a portfolio of successfully completed projects can provide invaluable insights into a manufacturer's reliability and customer satisfaction. Long-standing service in the industry often indicates stability, expertise, and a proven track record. Furthermore, consider their after-sales support, including warranty policies, technical assistance, and responsiveness to inquiries or issues. A manufacturer that prioritizes customer support ensures a smoother project lifecycle from specification through installation and beyond. Ultimately, the choice should lean towards a partner who offers not just a product, but a complete solution, combining high-quality Hot Dipped Galvanized Steel Grating/Bar Grating with expert technical support, reliable logistics, and a commitment to long-term client relationships, thereby ensuring a supply chain that contributes to the project's overall success and operational longevity.

Real-World Applications and Illustrative Case Studies

The practical application of Hot Dipped Galvanized Steel Grating/Bar Grating extends across countless projects globally, demonstrating its adaptability and essential role in diverse infrastructure developments. Consider, for instance, a significant expansion project for a major seaport terminal in a highly corrosive marine environment. The challenge was to construct elevated walkways, gangways, and service platforms that could withstand constant exposure to saltwater spray, heavy loads from equipment and personnel, and continuous outdoor weathering. Traditional painted steel would require frequent and costly maintenance due to rapid corrosion. The solution involved specifying thousands of square meters of serrated, hot-dipped galvanized steel grating with specific bearing bar dimensions designed to handle substantial live loads while ensuring superior slip resistance for operational safety. The grating panels were custom-fabricated with precise cut-outs for pipes and machinery, minimizing on-site modifications and expediting installation. This project significantly benefited from the HDG grating's extended service life and minimal maintenance requirements, leading to substantial long-term cost savings and ensuring uninterrupted port operations, proving its economic advantage and reliability in critical infrastructure. The inherent durability and long-term performance under such harsh conditions exemplify why it is the material of choice for marine and coastal applications, outperforming alternatives by a significant margin in terms of total cost of ownership and operational uptime.

Another compelling example involves a large-scale wastewater treatment facility upgrade in a densely populated urban area. The facility required new access platforms, stairways, and trench covers around aeration basins, clarifiers, and pump houses, areas characterized by high humidity, exposure to corrosive gases (e.g., hydrogen sulfide, chlorine), and continuous pedestrian traffic. The primary concerns were worker safety, long-term structural integrity in a chemically aggressive atmosphere, and efficient drainage. Hot-dipped galvanized steel grating was selected for its exceptional corrosion resistance and its open design, which facilitates excellent ventilation to dissipate noxious gases and ensures rapid drainage of water and sludge, preventing hazardous accumulations. Custom fabrication was again essential to fit the unique contours of the various tanks and equipment, including circular grating sections and panels with specific cut-outs for mechanical components. The project successfully implemented a highly durable and safe working environment, significantly reducing future maintenance burdens compared to using less resistant materials. This showcases how the material not only provides a safe and durable access solution but also contributes to the operational efficiency and environmental control within specialized industrial settings, directly addressing the unique challenges posed by wastewater treatment processes. The ease of installation, even for complex geometries, further accelerated project timelines, demonstrating a comprehensive value proposition that combines product performance with project management efficiency.

Ensuring Quality and Compliance: Authoritative Standards and Testing

The authoritative standards and rigorous testing protocols underscore the reliability and trustworthiness of Hot Dipped Galvanized Steel Grating/Bar Grating. Compliance with international and national standards is not merely a bureaucratic requirement but a fundamental assurance of quality, safety, and performance. Key among these are the ASTM (American Society for Testing and Materials) standards, specifically ASTM A123/A123M for hot-dip galvanization of iron and steel products, which specifies minimum zinc coating thickness based on material thickness and ensures proper adhesion and uniformity of the coating. For the grating itself, ANSI/NAAMM MBG 531 (American National Standards Institute/National Association of Architectural Metal Manufacturers Metal Bar Grating Manual) provides comprehensive guidelines for load tables, deflection limits, materials, and fabrication tolerances. In Europe, EN ISO 1461 dictates the hot-dip galvanized coatings on fabricated iron and steel articles, while EN 10025 specifies the technical delivery conditions for hot-rolled structural steel, the base material for the grating. Manufacturers committed to excellence also adhere to ISO 9001, an internationally recognized standard for quality management systems, which ensures that all stages of design, production, installation, and servicing are consistently monitored and controlled to meet customer requirements and regulatory obligations, thereby minimizing defects and maximizing product reliability throughout its lifecycle, leading to greater customer confidence and repeat business for critical infrastructure projects.

Beyond adherence to standards, reputable manufacturers implement extensive in-house and third-party testing procedures. This includes destructive and non-destructive testing for coating thickness, using methods like magnetic induction gauges or X-ray fluorescence, to verify compliance with galvanization specifications. Mechanical load testing, often conducted in accordance with NAAMM or equivalent standards, verifies the grating's actual load-bearing capacity and deflection under various load scenarios, replicating real-world application stresses. Visual inspections are conducted at multiple stages – after fabrication, after galvanization, and before packaging – to check for dimensional accuracy, weld quality, surface defects, and overall finish. Material traceability is also a critical aspect, with manufacturers maintaining detailed records of raw material origins, mill certificates, and processing data for each batch, allowing for full accountability and recall if necessary. This meticulous approach to quality assurance and control, backed by robust documentation and independent audits, provides end-users with the confidence that the Hot Dipped Galvanized Steel Grating/Bar Grating they receive is not only compliant with all relevant technical specifications but also guaranteed to perform reliably and safely for its intended service life, providing peace of mind to project managers and engineers who are responsible for the long-term integrity and safety of their industrial assets.

Trust and Support: FAQs, Delivery, Warranty, and Customer Service

Building trust with B2B clients extends beyond delivering a high-quality product; it encompasses comprehensive support, clear communication, and transparent policies. Addressing common questions upfront through a detailed FAQ section, providing clear insights into delivery processes, offering robust warranty commitments, and ensuring accessible customer support are pivotal. A well-structured FAQ module can preemptively answer client queries regarding product types, load capacities, installation methods, maintenance, and ordering procedures, thereby streamlining the communication flow and enhancing customer satisfaction. For instance, questions like "What is the typical lifespan of hot-dipped galvanized steel grating?" or "Can the grating be customized for unusual shapes?" are frequently asked and can be addressed comprehensively, demonstrating expertise and responsiveness. Furthermore, transparent communication regarding delivery schedules and logistics is crucial for project planning. Manufacturers should provide clear information on lead times, shipping options (e.g., LCL, FCL, air freight), packaging standards to prevent transit damage, and procedures for international customs and documentation, ensuring that project timelines are met and potential delays are minimized. This level of detail in logistical planning reflects a commitment to timely and efficient project execution, a critical factor for large-scale industrial endeavors where delays can incur significant costs and operational disruptions.

A strong warranty commitment further solidifies trust. Reputable manufacturers typically offer warranties covering manufacturing defects and galvanization quality for a specified period, demonstrating confidence in their product's durability and adherence to standards. Details regarding the warranty scope, claims process, and specific conditions should be clearly outlined. For instance, a warranty might cover the integrity of the hot-dip galvanized coating for a period of 5-10 years under normal environmental conditions, provided the grating has been installed and maintained correctly. Complementing this, responsive and knowledgeable customer support is paramount. This includes readily available technical assistance for design and installation queries, efficient handling of order modifications, and prompt resolution of any post-delivery issues. Channels for support, such as dedicated account managers, technical hotlines, and online portals, should be clearly communicated. The synergy of these elements – a clear FAQ, transparent delivery processes, a solid warranty, and accessible customer support – creates a holistic service experience that instills confidence and fosters long-term partnerships, ensuring that every purchase of Hot Dipped Galvanized Steel Grating/Bar Grating is backed by a commitment to excellence and client success, which is a key differentiator in the B2B landscape where reliability and partnership are valued as highly as the product itself.

Frequently Asked Questions (FAQ)

-

Q: What is the primary difference between welded and pressure-locked steel grating?

A: Welded steel grating features bearing bars and cross bars joined by resistance welding, offering robust structural integrity suitable for heavy-duty applications. Pressure-locked grating, on the other hand, interlocks the bars mechanically under intense pressure, creating a clean, aesthetically pleasing joint often preferred for architectural uses. Both types can be hot-dip galvanized for corrosion resistance, but their fabrication methods and resulting appearances differ.

-

Q: How does hot-dip galvanization compare to other corrosion protection methods for steel grating?

A: Hot-dip galvanization provides superior, long-lasting corrosion protection compared to painting or powder coating. It forms a metallurgical bond with the steel, creating tough zinc-iron alloy layers and an outer pure zinc layer. This offers both barrier protection and cathodic (sacrificial) protection, meaning the zinc corrodes preferentially to protect the steel, even if scratched. This results in a service life of decades in many environments, significantly reducing maintenance needs compared to other coatings that only offer barrier protection and can be easily compromised.

-

Q: Can Hot Dipped Galvanized Steel Grating/Bar Grating be customized for specific project dimensions and load requirements?

A: Absolutely. Most reputable manufacturers offer extensive customization options. This includes fabricating panels to exact lengths, widths, and complex shapes (e.g., curves, circles, irregular cut-outs) to fit specific architectural or structural designs. Bearing bar depth, thickness, and spacing can be engineered to meet precise load capacities and deflection limits, ensuring optimal performance and safety for any application, from light pedestrian traffic to heavy industrial loads. Surface finishes (plain or serrated) and edge banding options are also customizable.

-

Q: What inspection standards should I look for when sourcing galvanized steel grating?

A: When sourcing, ensure the manufacturer adheres to recognized international and national standards. For galvanization, look for ASTM A123/A123M (USA) or ISO 1461 (International). For the grating's structural design and fabrication, key standards include ANSI/NAAMM MBG 531 (USA), BS 4592 (UK), DIN 24537 (Germany), or YB/T 4001.1 (China). Adherence to ISO 9001 (Quality Management) is also a strong indicator of a reliable supplier. These standards ensure consistent quality, performance, and safety.

-

Q: Is galvanized steel grating environmentally friendly?

A: Yes, it is considered highly environmentally friendly. Steel is one of the most recycled materials globally, and galvanized steel is 100% recyclable without loss of properties. The zinc used in galvanization is a naturally occurring element. Furthermore, the longevity and low maintenance requirements of hot-dipped galvanized grating reduce the need for frequent replacements and ongoing chemical treatments (like painting), leading to a smaller environmental footprint over its entire lifecycle. This aligns with modern sustainability goals and green building initiatives.

Future Outlook and Industry Insights

The trajectory for Hot Dipped Galvanized Steel Grating/Bar Grating remains robust, driven by ongoing global industrialization, infrastructure development, and a continuous focus on safety and efficiency. Emerging trends suggest a growing integration of smart manufacturing principles in grating production, leading to increased automation, higher precision, and more efficient resource utilization. The evolution of specialized anti-corrosion coatings applied over galvanization could also emerge for niche applications in extremely aggressive chemical environments, extending the already impressive service life of the material. Furthermore, designers are increasingly exploring the aesthetic potential of grating, incorporating it into modern architectural facades, urban furniture, and public art installations, expanding its market beyond traditional industrial applications. This blend of utilitarian strength and architectural appeal will likely open new avenues for growth and innovation within the sector. The enduring relevance of hot-dipped galvanized steel grating is firmly rooted in its fundamental value proposition: a highly durable, cost-effective, and safe solution for critical access and support structures in challenging environments. As industries continue to prioritize long-term asset performance and sustainability, the demand for this proven material is expected to remain strong, solidifying its indispensable position in the global infrastructure landscape.

Looking forward, industry forums and academic research point to continued advancements in steel alloys and galvanization techniques, aiming for even greater strength-to-weight ratios and enhanced corrosion resistance in extreme conditions. Discussions within professional engineering communities often highlight the life-cycle cost benefits of hot-dipped galvanized steel, consistently positioning it as a superior investment compared to alternatives that require frequent maintenance or early replacement. As noted in a recent industry symposium on infrastructure resilience, "The total cost of ownership for assets incorporating hot-dip galvanized steel frequently demonstrates a compelling advantage, primarily due to dramatically reduced maintenance interventions and extended operational lifespans." Similarly, a paper published in a leading materials science journal emphasized that "the metallurgical bond formed during hot-dip galvanization provides a level of integrity and sacrificial protection unmatched by simple barrier coatings, making it a benchmark for corrosion prevention in exposed steel structures." These insights underscore the technical and economic rationale behind the sustained preference for Hot Dipped Galvanized Steel Grating/Bar Grating in demanding B2B applications worldwide, affirming its status as a foundational element for resilient and sustainable industrial development.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025