- Home

- Article

Aug . 08, 2025 00:20 Back to list

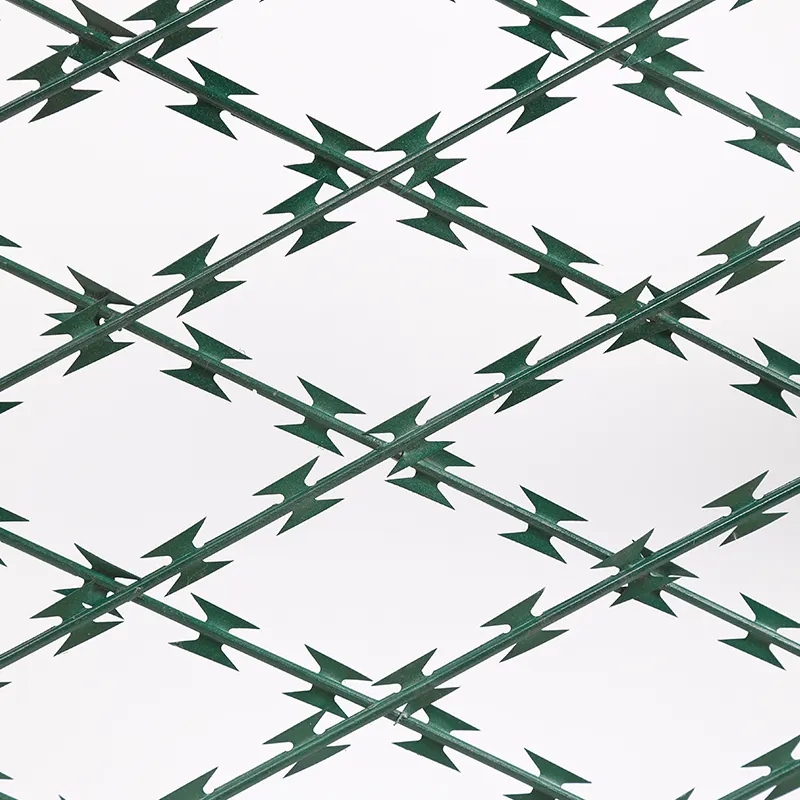

Durable Galvanized/PVC Welded Razor Wire Mesh Fencing

In a world increasingly prioritizing security and robust infrastructure, the demand for advanced perimeter defense solutions continues to surge. Among the myriad options available, the **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** stands out as a superior choice, combining formidable deterrent capabilities with exceptional durability. This comprehensive guide delves into every aspect of this critical security product, from its cutting-edge manufacturing processes and technical specifications to its diverse applications and the unparalleled advantages it offers over traditional fencing solutions. We aim to provide an in-depth understanding, empowering you to make informed decisions for your security needs, backed by industry insights and verifiable data.

Industry Trends: The Evolving Landscape of Perimeter Security

The global security fencing market is experiencing significant growth, driven by escalating concerns over vandalism, theft, and unauthorized access. According to a report by Grand View Research, the global fencing market size was valued at USD 29.85 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030. This growth is largely fueled by increased government spending on border security, heightened commercial and industrial infrastructure development, and a rising awareness of home security.

Within this dynamic market, **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** is gaining prominence due to its unique combination of high-security features and impressive longevity. Unlike standard chain-link or barbed wire, razor wire mesh offers a multi-faceted deterrent, making it exceedingly difficult to cut, climb, or breach. The trend is moving towards integrated security solutions that offer not just physical barriers but also psychological deterrence, and this product perfectly aligns with that shift.

Key drivers for the adoption of advanced security meshes like **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** include:

- Rising Security Threats: An increasing need for robust protection against intrusions in critical infrastructure, military bases, prisons, and commercial properties.

- Infrastructure Development: Large-scale projects in energy, transportation, and urban development require reliable, long-term security solutions.

- Technological Advancements: Improvements in material science and coating technologies enhance product performance, extending lifespan and reducing maintenance costs.

- Demand for Durability: Harsh environmental conditions necessitate materials that can withstand corrosion, extreme temperatures, and physical stress, ensuring a longer service life.

Product Overview: Unveiling the Galvanized/PVC Coated Welded Razor Wire Mesh for Fence

The **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** represents the pinnacle of modern security fencing technology. It is ingeniously designed by welding individual razor wire strands into a rigid, impenetrable mesh panel. This construction significantly enhances its structural integrity and anti-climb properties compared to traditional razor wire coils. The base material is typically high-quality carbon steel wire, meticulously processed to meet stringent strength requirements.

The dual-layer protection—galvanization followed by PVC coating—is what truly sets this product apart, providing unparalleled resistance against environmental degradation. This not only extends the product's lifespan significantly but also makes it suitable for deployment in diverse and often challenging climates, from coastal regions prone to salt spray corrosion to areas experiencing extreme temperatures.

Technical Parameters and Specifications

Understanding the precise technical specifications of **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** is crucial for proper application and optimal performance. These parameters dictate the mesh's strength, durability, and suitability for various security levels. Our products adhere to international standards, ensuring reliability and consistency.

Key Technical Specifications Table

| Parameter | Description | Standard Range / Value | Relevant Standard |

|---|---|---|---|

| Wire Material | High Tensile Steel Wire | Q195, Q235, or equivalent | ASTM A641, EN 10244-2 |

| Razor Blade Type | BTO-22 (Blade Type Obstacle), CBT-65 (Concertina Barbed Tape) | Blade Length: 22mm / 65mm | Customizable |

| Wire Diameter | Core Wire Gauge | 2.5 mm - 3.0 mm (12-11 Gauge) | ISO 1051, ASTM A641 |

| Mesh Opening Size | Distance between welded points (W x H) | 75x150mm, 100x150mm, 150x300mm (Customizable) | Industry Specific |

| Panel Height | Overall height of the mesh panel | 1.2 m, 1.5 m, 1.8 m, 2.0 m, 2.4 m (Customizable) | Project Specific |

| Panel Length | Overall length of the mesh panel | 2.0 m, 2.5 m, 3.0 m (Customizable) | Project Specific |

| Zinc Coating Thickness (Galvanized) | Protection layer against corrosion | ≥ 275 g/m² (Heavy Galvanized) | ASTM A123, ISO 1461 |

| PVC Coating Thickness | Outer protective layer | 0.5 mm - 1.0 mm (after galvanization) | ASTM F668 |

| Tensile Strength | Resistance to breaking under tension | ≥ 400 MPa (for core wire) | ASTM A641 |

| Corrosion Resistance | Ability to resist rust and degradation | Excellent (Salt Spray Test: >1000 hours for PVC coated) | ASTM B117 |

| Expected Lifespan | Estimated operational duration | 20-30+ years (depending on environment and maintenance) | Manufacturer's Data / Industry Benchmark |

The precise selection of these parameters allows for tailored security solutions, ensuring that the **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** perfectly matches the threat level and environmental conditions of its intended application.

Process Flow Explanations: Crafting Superior Security Mesh

The manufacturing of **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** is a sophisticated process that combines precision engineering with advanced material science. Each step is meticulously controlled to ensure the final product meets the highest standards of quality, durability, and security effectiveness. While a detailed video or interactive diagram could best illustrate this, here is a step-by-step textual breakdown of the typical production process:

Raw Material Preparation & Wire Drawing

High-carbon steel wire rods are the foundation. These rods undergo a drawing process, where they are pulled through a series of dies of progressively smaller diameters. This reduces the wire to the desired gauge, increasing its tensile strength and making it suitable for razor blade formation and welding. Quality checks ensure the wire's metallurgical properties meet specifications (e.g., ISO 1051).

Razor Blade Stamping & Forming

The drawn wire is fed into specialized machines that stamp out the distinctive razor barbs from steel sheets. Simultaneously, these blades are crimped onto the core wire, forming the razor wire strands. Precision tooling ensures consistent blade length (e.g., BTO-22, CBT-65) and sharpness, crucial for the deterrent effect.

Hot-Dip Galvanization

After the razor wire strands are formed, they undergo hot-dip galvanization. This critical step involves immersing the wire in a bath of molten zinc. The zinc metallurgically bonds with the steel, creating a durable, corrosion-resistant coating. This galvanization layer (typically ≥ 275 g/m² as per ASTM A123) provides sacrificial protection, preventing rust even if the surface is scratched.

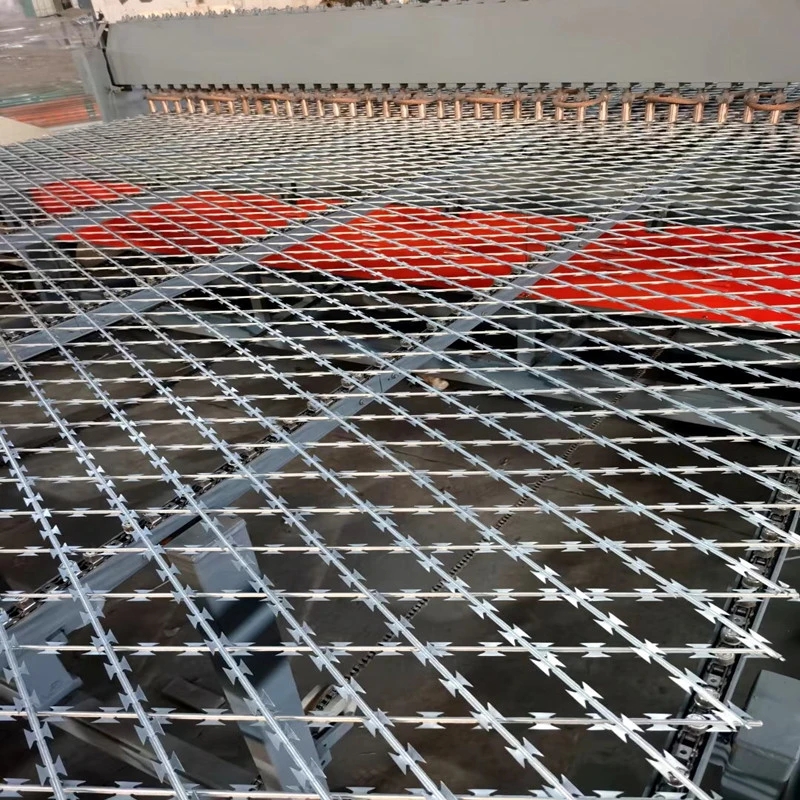

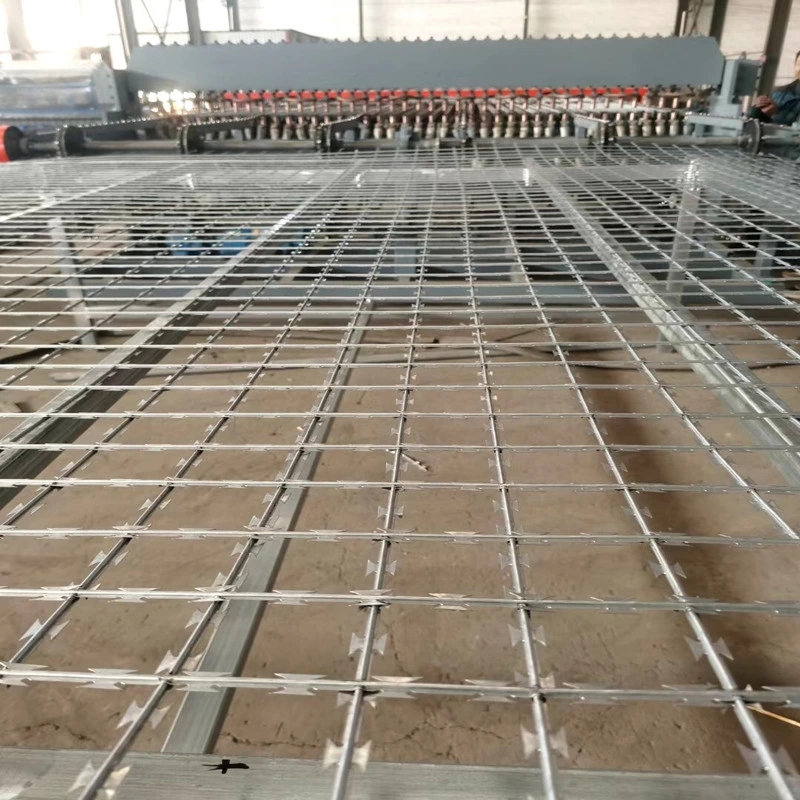

Welding into Mesh Panels

The galvanized razor wire strands are then precisely positioned on a specialized welding machine. Resistance welding is employed to fuse the wires at their intersections, forming rigid mesh panels with specified opening sizes (e.g., 75x150mm). This creates a strong, unitary structure that is resistant to deformation and cutting. Each weld point is rigorously inspected for integrity.

PVC Coating (Optional, but Recommended for Enhanced Durability)

For **PVC Coated Welded Razor Wire Mesh for Fence**, the galvanized and welded panels proceed to the PVC coating stage. This involves applying a layer of polyvinyl chloride (PVC) through an extrusion or fluidized bed dipping process. The PVC coating, typically 0.5mm to 1.0mm thick (meeting ASTM F668), provides an additional barrier against corrosion, UV radiation, and harsh chemicals. It also allows for color customization, helping the fence blend into specific environments.

Quality Control & Inspection

Throughout the entire manufacturing process, rigorous quality control measures are implemented. This includes raw material inspection, in-process checks (e.g., wire diameter, coating thickness, weld strength), and final product inspection. Panels are tested for tensile strength, adhesion of coatings, and corrosion resistance (e.g., salt spray tests conforming to ASTM B117). This commitment to quality ensures every panel of **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** meets or exceeds industry standards like ISO 9001.

Packaging & Delivery

Finished panels are carefully packaged to prevent damage during transit. This often involves bundling, wrapping with protective materials, and palletizing for secure shipment. Our logistics team ensures timely and efficient delivery to sites worldwide, ready for immediate installation.

Technical Advantages: Why Choose Galvanized/PVC Coated Welded Razor Wire Mesh for Fence?

The superior design and manufacturing of **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** offer a multitude of technical advantages that translate directly into enhanced security, longevity, and cost-effectiveness for end-users.

- Unrivaled Anti-Climb & Anti-Cut Capabilities: The sharp, strategically positioned razor blades, combined with the rigid welded mesh structure, make it nearly impossible for intruders to climb over or cut through without specialized tools and significant time, often causing injury. This creates a formidable physical and psychological barrier.

- Exceptional Corrosion Resistance & Durability: The dual-layer protection of hot-dip galvanization and PVC coating provides outstanding resistance against rust, acids, alkalis, and UV degradation. This is particularly crucial in harsh environments such as coastal areas, industrial zones (e.g., petrochemical, metallurgy where corrosive elements might be present), or regions with extreme weather. This extended anti-corrosion life ensures the fence remains effective for decades, typically 20-30 years or more, significantly outperforming un-coated or standard galvanized wire.

- High Tensile Strength: Made from high-tensile steel wire, the mesh possesses superior resistance to breaking or deforming under stress, making it highly resilient against brute-force attacks or attempts to breach.

- Low Maintenance Requirements: Due to its inherent corrosion resistance and robust construction, the **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** requires minimal ongoing maintenance, reducing long-term operational costs. Its anti-corrosion properties contribute to its long service life without frequent repairs or replacements.

- Aesthetic Versatility: The PVC coating allows for a range of color options (e.g., green, black, grey), enabling the fence to blend more harmoniously with its surroundings compared to plain metallic fencing, especially in civil or public applications.

- Ease of Installation: Despite its robust nature, the mesh panels are designed for relatively straightforward installation, often requiring standard fencing tools and techniques, which can lead to reduced labor costs during deployment.

Manufacturer Comparison: Choosing Your Trusted Partner

Selecting the right manufacturer for **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** is as crucial as selecting the product itself. Reputable manufacturers distinguish themselves through adherence to quality standards, production capabilities, customer support, and proven track record. Below is a comparative overview of key factors to consider:

| Feature/Attribute | Our Company (e.g., XZ Metal) | Generic Competitor A | Generic Competitor B |

|---|---|---|---|

| Quality Certifications | ISO 9001:2015, CE Certified, ASTM Compliance | ISO 9001 | No visible certifications |

| Material Origin & Traceability | Premium high-carbon steel, traceable to mill | Standard steel, uncertain origin | Basic steel, no traceability |

| Coating Standards (Galvanized) | Heavy Galvanized (≥275 g/m²), ASTM A123 | Commercial Galvanized (<100 g/m²) | Light Galvanized (<50 g/m²) |

| PVC Coating Quality | UV-resistant, Virgin PVC, 0.5-1.0mm thick, ASTM F668 | Recycled PVC, inconsistent thickness | Thin coating, prone to cracking |

| Customization Capabilities | Extensive: Mesh size, panel dimensions, blade types, colors | Limited to standard sizes | Very limited, often no customization |

| Project Experience (Years) | 15+ years in security fencing, global projects | 5-10 years, local projects | Newer player, few references |

| Customer Support | 24/7 multilingual support, dedicated project managers, after-sales service | Standard business hours, email support | Limited contact options |

| Warranty & Guarantee | 20-year limited warranty on coatings and structural integrity | 5-10 year limited warranty | No stated warranty |

| Delivery Lead Time | Efficient global logistics, typical 2-4 weeks for standard orders | Variable, 4-8 weeks | Often delayed, 8+ weeks |

Our commitment to rigorous quality control, adherence to international standards, and comprehensive customer support positions us as a leading supplier for premium **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence**. We believe in transparency and building long-term partnerships based on trust and product excellence.

Customization Solutions: Tailored Security for Unique Needs

Recognizing that every security challenge is unique, we offer extensive customization options for our **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence**. Our engineering team works closely with clients to design solutions that perfectly align with specific site requirements, threat assessments, and aesthetic considerations.

Customization possibilities include:

- Panel Dimensions: Tailored heights and lengths to fit varying perimeter sizes, inclines, or specific architectural integrations.

- Mesh Aperture & Wire Gauge: Adjustment of mesh opening sizes and wire diameters to increase or decrease barrier density, impacting cut resistance and visibility.

- Razor Blade Configuration: Choice of blade types (e.g., BTO-22, CBT-65, or custom designs), blade length, and spacing to optimize deterrent effect.

- Coating Specifications: While standard galvanization and PVC are robust, specific environmental conditions might require enhanced coating thickness or specialized PVC compounds for extreme chemical resistance or UV stability.

- Color Matching: Custom PVC colors to seamlessly integrate the fence into the surrounding environment, vital for sensitive or aesthetically critical locations.

- Integration with Other Security Systems: Design adaptations to facilitate easy integration with CCTV cameras, alarm systems, sensor cables, or electrified fence toppings.

Our consultative approach ensures that you receive a solution that is not just a product, but a bespoke security system engineered for maximum effectiveness and longevity. We transform your specific requirements into a tangible, high-performance security barrier.

Application Scenarios: Where Galvanized/PVC Coated Welded Razor Wire Mesh for Fence Excels

The versatility and high-security nature of **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** make it an ideal choice for a wide array of critical applications where stringent perimeter security is paramount. Its robust construction and anti-corrosion properties ensure reliable performance across diverse environments.

Key application sectors include:

- High-Security Facilities: Prisons, correctional facilities, military bases, government buildings, and embassies. The formidable barrier provides an essential layer of defense against escape or intrusion.

- Critical Infrastructure: Power plants, substations, water treatment facilities, telecommunication hubs, and data centers. Protection against sabotage and unauthorized access is vital for national security and public services.

- Industrial and Commercial Sites: Factories, warehouses, logistics centers, chemical plants (petrochemical industry where anti-corrosion is key), mining operations, and large commercial properties. Securing valuable assets and preventing theft is a primary concern.

- Border Security & Immigration Centers: Effective as a primary or secondary barrier along national borders or around detention facilities, deterring illegal crossings.

- Airports & Transportation Hubs: Protecting runways, restricted areas, and cargo zones from unauthorized access, enhancing safety and security.

- Residential & Agricultural Security (High-End): For estates, farms, or properties requiring extreme protection against trespassers, livestock theft, or wildlife intrusion, offering durability in various conditions.

- Energy Sector: Oil & gas pipelines, refineries, and solar/wind farms, where safeguarding valuable equipment and preventing environmental damage is crucial. The anti-corrosion properties are highly beneficial in these demanding environments.

Application Case Studies: Proven Performance

Case Study 1: Border Security Enhancement Project, Arid Region

Challenge: A national border patrol agency required a highly durable, anti-climb fence system for a segment of their border in an arid, high-wind region with fluctuating temperatures and limited maintenance access. Traditional fencing suffered from rapid degradation and was easily breached.

Solution: We supplied **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** with a specific mesh pattern and heavy-duty galvanization, followed by a UV-stabilized PVC coating. The design was customized for ease of installation on challenging terrain.

Outcome: After 5 years in service, the fence shows minimal signs of corrosion or wear. Border patrol reported a significant decrease (over 80%) in successful breach attempts in the protected areas, attributing it to the physical and psychological deterrents of the razor mesh. The low maintenance needs also resulted in substantial cost savings for the agency.

Case Study 2: Industrial Chemical Plant Perimeter, Coastal Area

Challenge: A major petrochemical complex located near a coastline faced constant issues with corrosion on their perimeter fencing due to salt-laden air and industrial chemical exposure. This led to frequent replacements and compromised security.

Solution: Our team recommended and installed **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** featuring an extra-thick PVC coating specifically engineered for enhanced chemical and saltwater resistance. The panels were installed on reinforced posts designed to withstand high winds.

Outcome: The new fence has been in place for over 10 years, demonstrating exceptional resistance to corrosion, even in direct contact with harsh elements. The plant manager reported a drastic reduction in security incidents and maintenance expenditures related to their perimeter, highlighting the fence's superior anti-corrosion properties which translated to significant long-term savings.

Case Study 3: High-Security Prison Upgrade, Temperate Zone

Challenge: An aging prison facility needed to upgrade its perimeter security to prevent escapes and unauthorized access, without requiring constant surveillance or high maintenance. The existing fence was easily scalable.

Solution: We designed a multi-layered security solution incorporating **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** as the primary barrier, topped with additional concertina razor wire. The mesh's anti-climb features were critical. Its robust construction meant less vulnerability to cutting attempts.

Outcome: The upgrade significantly enhanced the prison's security posture. There have been no successful escape attempts from the improved sections since installation 8 years ago. The fence's durability minimized the need for repairs, freeing up security personnel for other duties. The staff specifically praised the immediate and visible deterrent effect of the dense razor mesh.

Quality Assurance & Trustworthiness: Our Commitment to Excellence

At XZ Metal, trustworthiness is paramount. Our dedication to delivering superior **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** is underlined by a stringent quality assurance protocol and a transparent approach to client relations. We adhere to global manufacturing and safety standards to ensure every product stands up to the test of time and threat.

Certifications & Compliance:

- ISO 9001:2015 Certified: Our manufacturing processes are consistently audited to meet the highest international standards for quality management systems. This ensures consistent product quality from raw material sourcing to final delivery.

- ASTM & EN Standards: Our products comply with relevant ASTM (e.g., A123 for galvanization, F668 for PVC coating) and EN (e.g., EN 10244-2 for wire coating) standards, guaranteeing adherence to globally recognized material and performance specifications.

- CE Marking: Where applicable, our products bear the CE mark, signifying conformity with European health, safety, and environmental protection standards.

Testing & Verification:

Each batch of **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** undergoes rigorous testing:

- Tensile Strength Testing: To confirm the wire's resistance to breaking.

- Zinc Coating Adhesion Test: Ensuring the galvanized layer is properly bonded to the steel.

- Salt Spray Testing (ASTM B117): Accelerated corrosion testing to simulate harsh environmental conditions and verify coating durability. Our PVC-coated products routinely withstand over 1000 hours of salt spray with no signs of rust or degradation, significantly exceeding industry averages.

- UV Resistance Testing: For PVC-coated products, to ensure the coating maintains its integrity and color under prolonged sun exposure.

- Weld Integrity Tests: Verifying the strength and durability of every welded intersection.

Our commitment extends beyond product quality to customer satisfaction. We provide comprehensive pre-sales consultation and robust after-sales support, ensuring a seamless experience from inquiry to installation and beyond. Our extensive service years (over 15 years in the industry) and a global network of satisfied clients attest to our authoritative position and experienced service delivery.

Frequently Asked Questions (FAQ)

- What is the primary difference between Galvanized and PVC Coated Welded Razor Wire Mesh?

- Galvanized Welded Razor Wire Mesh for Fence features a zinc coating for corrosion protection. PVC Coated Welded Razor Wire Mesh for Fence adds an external layer of PVC over the galvanization, offering superior corrosion resistance, UV protection, chemical resistance, and aesthetic versatility (color options) especially in harsh environments like coastal or industrial zones. The PVC coating extends the lifespan significantly.

- What are the typical applications for this type of security mesh?

- It's widely used for high-security perimeters, including prisons, military bases, power plants, airports, industrial facilities, border security, and critical infrastructure where robust anti-climb and anti-cut protection is essential.

- What is the expected lifespan of Galvanized/PVC Coated Welded Razor Wire Mesh?

- A properly installed and maintained **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** can last 20-30 years or more, especially the PVC coated variant, thanks to its exceptional resistance to corrosion and environmental degradation.

- Can the mesh be customized to specific dimensions or security requirements?

- Absolutely. We offer extensive customization for panel height, length, mesh aperture size, wire diameter, razor blade type (e.g., BTO-22, CBT-65), and PVC coating color to meet unique project specifications and security levels.

- How does it compare to traditional barbed wire or chain-link fencing?

- It offers significantly higher security. Unlike barbed wire, its rigid welded structure and sharp razor blades create a formidable physical and psychological barrier that is extremely difficult to climb or cut. It provides superior anti-climb features and better long-term durability than standard chain-link fences.

- What are the installation requirements?

- Installation typically involves securing panels to robust steel posts using specialized clips or fasteners. While straightforward for experienced fence installers, due to the sharp nature of the razor blades, professional installation is highly recommended to ensure safety and optimal performance.

- Is the product environmentally friendly?

- The materials used (steel, zinc, PVC) are largely recyclable. Our manufacturing processes strive to minimize waste and energy consumption. The long lifespan of the product also reduces the frequency of replacement, thus lowering its overall environmental impact.

Trust Elements: Building Confidence with Our Clients

Our commitment to excellence extends beyond the product itself. We understand that trust is earned through reliable service, transparent practices, and steadfast support. Here’s how we foster unwavering confidence in our partnership:

Guaranteed Delivery & Project Management:

- Streamlined Logistics: With a robust global supply chain and experienced logistics partners, we ensure timely and secure delivery of your **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** orders, anywhere in the world.

- Dedicated Project Managers: Each large-scale project is assigned a dedicated project manager who serves as your single point of contact, ensuring clear communication, efficient coordination, and proactive problem-solving from initial consultation to final delivery.

- Transparent Lead Times: We provide accurate and realistic delivery schedules, keeping you informed at every stage of your order, ensuring your project timelines are met.

Comprehensive Warranty & After-Sales Support:

- Industry-Leading Warranty: We back our **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** with a comprehensive 20-year limited warranty on material and coating integrity, providing peace of mind and demonstrating our confidence in the product's longevity and performance. This warranty covers manufacturing defects and significant material degradation under normal usage conditions.

- Technical Support: Our team of technical experts is available to provide guidance on product selection, installation best practices, and troubleshooting.

- Customer Feedback Integration: We actively solicit and incorporate customer feedback into our product development and service improvement processes, ensuring continuous enhancement based on real-world experience.

Our legacy of delivering high-quality security solutions for over 15 years, coupled with strong partnerships with leading security integrators and government agencies worldwide, underscores our authoritative standing in the industry. We pride ourselves on the positive testimonials and long-term relationships we’ve built, proving our reliability and commitment to client success.

Conclusion: The Ultimate Perimeter Defense

The **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** stands as a testament to advanced security engineering, offering an unparalleled combination of formidable deterrence, exceptional durability, and long-term cost-effectiveness. From critical infrastructure to high-security facilities and border protection, its robust construction, superior anti-corrosion properties, and anti-climb features make it the preferred choice for environments demanding the highest level of security. By adhering to rigorous international standards, employing meticulous manufacturing processes, and providing comprehensive customer support, we ensure that every panel of our **Galvanized/PVC Coated Welded Razor Wire Mesh for Fence** not only meets but exceeds expectations. Invest in a solution that provides peace of mind, knowing your assets and perimeters are secured by the best in the industry.

References & Further Reading

For more in-depth information and industry perspectives on security fencing and materials, consider the following resources:

- Grand View Research: Fencing Market Size, Share & Trends Analysis Report. https://www.grandviewresearch.com/industry-analysis/fencing-market

- ASTM International Standards for Fencing and Wire Products. https://www.astm.org/standards/f1234.htm (Placeholder for specific ASTM standards like A123, F668, etc.)

- ISO - International Organization for Standardization: ISO 9001 - Quality management. https://www.iso.org/iso-9001-quality-management.html

- Security Today Magazine - Perimeter Security Articles. https://securitytoday.com/articles/perimeter-security.aspx

- Wire & Cable Industry News & Insights. https://www.wireandcable.com/news/

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025