Oct . 19, 2025 10:45 Back to list

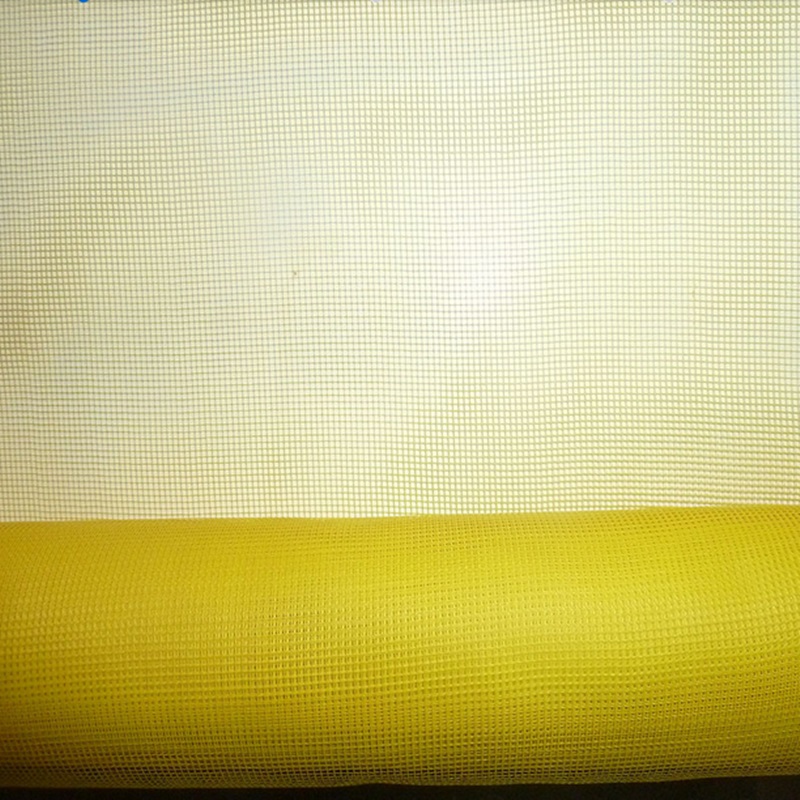

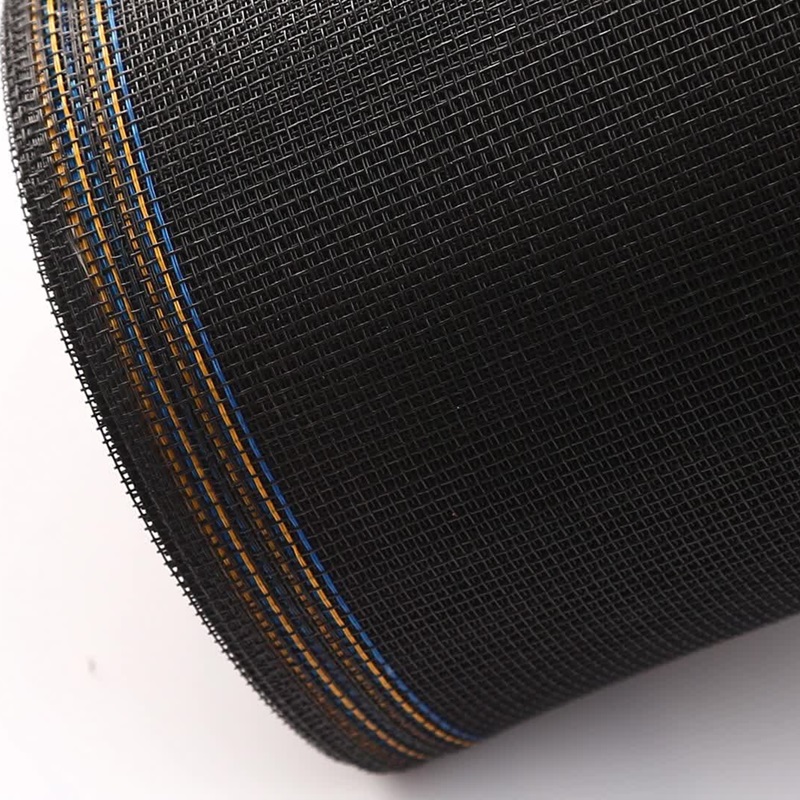

Plastic Window Screen & Plastic Insect Mesh - UV-Resistant

Plastic window screen/plastic insect mesh: 2025 Buyer’s Field Notes

If you’ve been sourcing mesh lately, you’ve probably noticed the quiet shift: PE monofilament has gone from “budget” to “default.” I’ve been on factory floors in Hebei and coastal retrofit sites where the first question is no longer “steel or fiberglass?”—it’s whether Plastic window screen/plastic insect mesh can hit the airflow and UV targets without blowing the budget. Short answer: yes, with caveats.

What’s driving the trend

Modern HDPE monofilament, UV-stabilized and heat-set, delivers clean apertures, decent hand feel, and long outdoor life—even in harsh sun. In fact, many customers say the matte black finish “disappears” against glazing better than fiberglass. And yes, price volatility is gentler than aluminum wire these days.

| Spec | Typical value (≈) | Notes (real‑world may vary) |

|---|---|---|

| Material | HDPE monofilament | Polyethylene; UV masterbatch |

| Mesh count | 18×16, 14×14 | Window standard; custom on request |

| Filament dia. | ≈0.20–0.28 mm | Balancing strength & visibility |

| Aperture | ≈1.0–1.4 mm | Mosquito/gnat control |

| Width × length | 1.0–1.8 m × 30/50/100 m | Custom rolls available |

| Color | Black, gray | Black best for glare control |

| Certification | ISO 9001 | Factory QMS audited |

Process flow (how it’s actually made)

Resin selection → UV masterbatch dosing → monofilament extrusion → precision weaving (plain weave) → heat-setting → edge trimming → inspection & mesh-count verification → roll winding → packaging.

Testing: tensile (ASTM D638), fabric count (ASTM D3775), UV weathering (ISO 4892‑3/ASTM G154), dimensional stability (heat set), and visual defects. Service life: around 5–8 years outdoors depending on UV index and salt exposure—I’ve seen coastal installs hit the lower end, honestly.

Applications I keep seeing

- Residential and hotel window/door screens (retrofits love it).

- Food processing vents where corrosion is a headache.

- Greenhouse and livestock barns for insect pressure control.

- Printing field: protective layers, ink filtration pre-screens, and shop partitions.

Why spec Plastic window screen/plastic insect mesh?

- Corrosion-proof vs. salty air; quieter to cut and fit than metal.

- Consistent apertures from heat-set weaving improve airflow predictability.

- Lower total cost of ownership; easy to clean; no paint flake issues.

Vendor landscape (quick compare)

| Vendor | Lead time | Customization | Certs | Cost (≈) |

|---|---|---|---|---|

| XZ Metal (Anping, Hebei) | 7–15 days | Widths, mesh counts, labels | ISO 9001 | Value/mid |

| Local fabricator | 2–4 weeks | Limited | Varies | Mid |

| Import brand (EU/US) | 4–8 weeks | Good | Multiple | Premium |

Customization & QA

Custom rolls, carton branding, and non-standard mesh counts are common. Typical lab snapshots I’ve seen: tensile ≥ 250–350 N/5 cm (warp/weft), UV retention ≥ 80% after 1,000 h (ISO 4892‑3), airflow kept high with 18×16 at ≈1.2 mm aperture. Certification: ISO 9001. Origin: 200 meters North Of Huangcheng Village, Anping, Hebei, China.

Mini case files

- Coastal hotel retrofit: switched to Plastic window screen/plastic insect mesh to stop corrosion staining—replaced less often, guests noticed clearer views.

- Food plant vents: gray mesh reduced glare on inspection lines; cleaning cycles extended to quarterly.

- Screen-print shop: used Plastic window screen/plastic insect mesh as protective layer on vacuum beds; fewer scratches, cheap to swap.

Bottom line? If you need clean apertures, decent UV life, and sane lead times, Plastic window screen/plastic insect mesh is the pragmatic pick—especially for high-humidity and coastal installs. Ask for UV test data and mesh-count certificates up front; it saves back-and-forth later.

Authoritative references

- ISO 9001:2015 – Quality management systems. https://www.iso.org/standard/62085.html

- ASTM D638 – Standard Test Method for Tensile Properties of Plastics. https://www.astm.org/d0638

- ASTM D3775 – Standard Test Method for End (Warp) and Pick (Filling) Count of Woven Fabrics. https://www.astm.org/d3775

- ISO 4892-3 – Plastics—Methods of exposure to laboratory light sources—Fluorescent UV lamps. https://www.iso.org/standard/72246.html

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025