Samh . 14, 2024 01:31 Back to list

pvc coated wire mesh manufacturers

Understanding PVC Coated Wire Mesh A Comprehensive Overview of Manufacturers and Applications

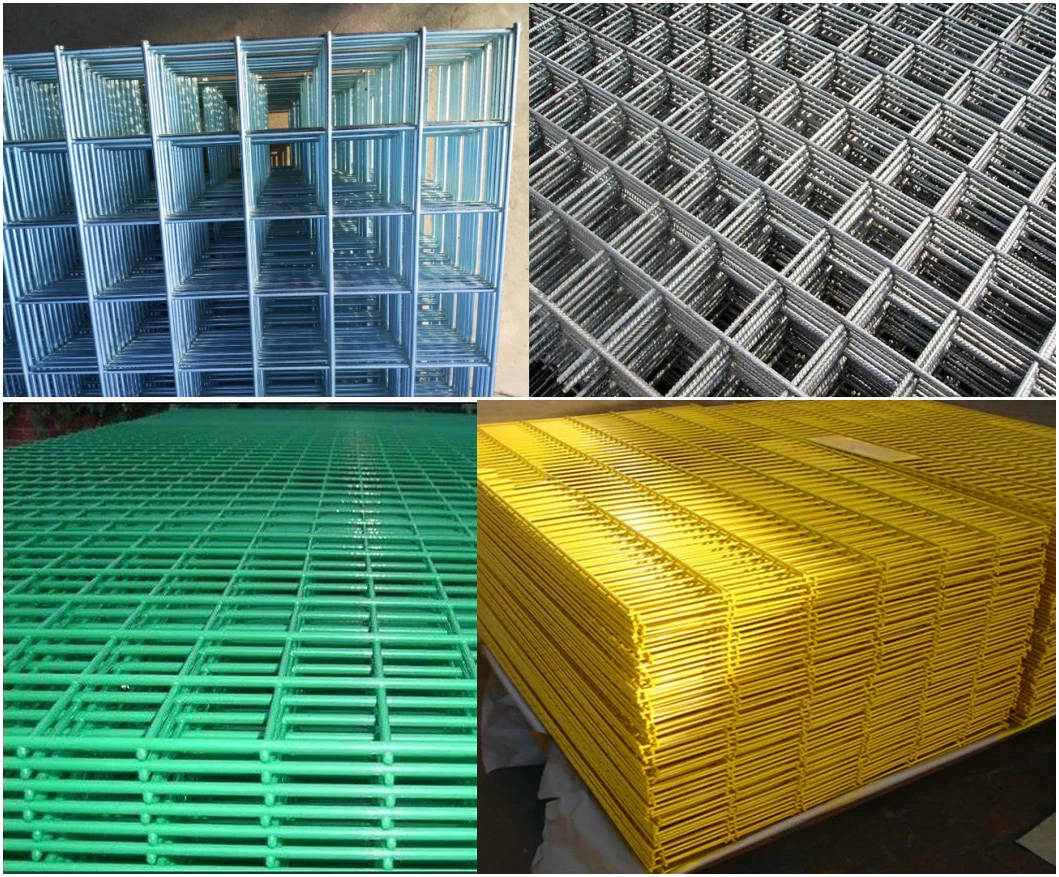

PVC coated wire mesh has emerged as a versatile and widely used material in various industries due to its durability, aesthetic appeal, and corrosion resistance. This type of wire mesh is coated with polyvinyl chloride (PVC), a plastic that significantly enhances its properties and usability. In this article, we will explore the key characteristics of PVC coated wire mesh, delve into its manufacturing process, and highlight some of the leading manufacturers in the industry.

Key Characteristics of PVC Coated Wire Mesh

1. Corrosion Resistance The primary advantage of PVC coating is its resistance to environmental factors. Unlike bare metal, which can rust and corrode over time, PVC-coated wire mesh remains protected from moisture, chemicals, and other corrosive substances, making it ideal for outdoor applications.

2. Aesthetic Appeal PVC coatings come in various colors, allowing for customization to fit the aesthetic needs of a project. This versatility makes it suitable for fencing, art installations, and decorative applications, where visual appearance is just as important as functionality.

3. Durability and Longevity The combination of high-quality steel and PVC coating provides excellent tensile strength, enabling the wire mesh to withstand high levels of stress and pressure. This durability translates into a longer lifespan compared to uncoated alternatives.

4. Safety Features The smooth surface of PVC-coated wire mesh reduces the risk of injury, making it an ideal choice for environments where humans and animals interact closely with the material, such as in cages, enclosures, and barriers.

Manufacturing Process of PVC Coated Wire Mesh

The manufacturing process of PVC coated wire mesh involves several steps

1. Wire Production High-quality steel wire is drawn into the desired gauge. The quality of the wire greatly influences the final product's strength and durability.

2. Welding or Weaving Depending on the application, the wire can be welded or woven into the desired mesh pattern. The welding process is typically used for panels, while weaving is more common for rolls of mesh.

pvc coated wire mesh manufacturers

4. Coating The cleaned wire mesh is then coated with PVC using a variety of methods, including extrusion or dipping. The thickness of the PVC layer can be adjusted based on the intended application, providing flexibility in protection levels.

5. Curing After coating, the mesh is cured in an oven. This process solidifies the PVC, ensuring a strong bond between the mesh and the coating.

6. Quality Testing Leading manufacturers perform rigorous quality tests to ensure that the PVC coated wire mesh meets industry standards. This includes tests for tensile strength, corrosion resistance, and other relevant properties.

Leading Manufacturers of PVC Coated Wire Mesh

The market for PVC coated wire mesh is saturated with numerous manufacturers, each offering unique products and services. Some of the notable manufacturers include

1. Anping County Shoufan Wire Mesh Products Co., Ltd. This China-based company specializes in various wire mesh products and has gained recognition for its high-quality PVC-coated options, serving both domestic and international markets.

2. Wire Coating Technologies, LLC Based in the USA, this company focuses on innovative coating technologies, offering a range of PVC coated wire products designed for both industrial and commercial purposes.

3. Bekaert A global leader in steel wire transformation, Bekaert provides high-quality PVC coated wire mesh solutions, ensuring consistency and reliability across its product range.

4. Welded Wire Mesh Manufacturer, Inc. Another key player in the industry, this manufacturer specializes in welded wire mesh and offers custom PVC coating solutions tailored to client specifications.

Conclusion

PVC coated wire mesh represents a robust, durable, and aesthetically pleasing solution for various applications. As industries grow and evolve, the demand for high-quality wire mesh products will continue to rise. Manufacturers play a pivotal role in this scenario, and understanding their offerings can help businesses make informed decisions about their wire mesh needs. Whether for fencing, construction, agriculture, or decorative uses, PVC coated wire mesh remains a superior choice in the wire mesh market.

-

High Quality 9 Gauge Expanded Metal Mesh & Chain Link Wire Mesh Fence Manufacturer

NewsJun.10,2025

-

Barbed Wire Roll Price - Wholesale Exporters & Reliable Factories Supply

NewsJun.10,2025

-

High-Quality Temporary Mesh Fence Panels for Sale Durable Temporary Fence Panels Supplier

NewsJun.10,2025

-

Welded Wire Fence Mesh Exporters Custom Sizes & Competitive Pricing

NewsJun.10,2025

-

Durable China Expanded Metal Security Mesh High-Security & Affordable

NewsJun.10,2025

-

White Expanded Metal Mesh Durable for Temp Fencing & Plaster

NewsJun.10,2025