Nov . 30, 2024 10:14 Back to list

wholesale scaffolding metal plank manufacturer

The Importance of Choosing the Right Wholesale Scaffolding Metal Plank Manufacturer

In the construction and renovation industry, scaffolding plays a pivotal role in ensuring safety and efficiency. Among the essential components of scaffolding systems are metal planks, which provide a stable walking platform for workers. When considering the procurement of these planks, selecting a reputable wholesale scaffolding metal plank manufacturer is crucial. This article will explore the importance of this choice, the factors to consider when selecting a manufacturer, and the benefits of using high-quality metal planks.

Why Choose a Reputable Manufacturer?

The safety of construction sites significantly relies on the integrity of the scaffolding system. Poor-quality metal planks can lead to accidents, injuries, and ultimately, project delays or failures. A reputable manufacturer ensures that the products meet industry standards for quality, safety, and durability. They employ rigorous testing and quality control measures to guarantee that all products withstand the demands of the construction environment.

Factors to Consider When Selecting a Manufacturer

1. Quality Assurance The first step in choosing a wholesale manufacturer is to evaluate their commitment to quality. Look for companies that produce planks meeting recognized industry standards, such as OSHA, ANSI, or ISO certifications. Quality assurance processes should be in place to ensure that every product leaving the factory is safe and reliable.

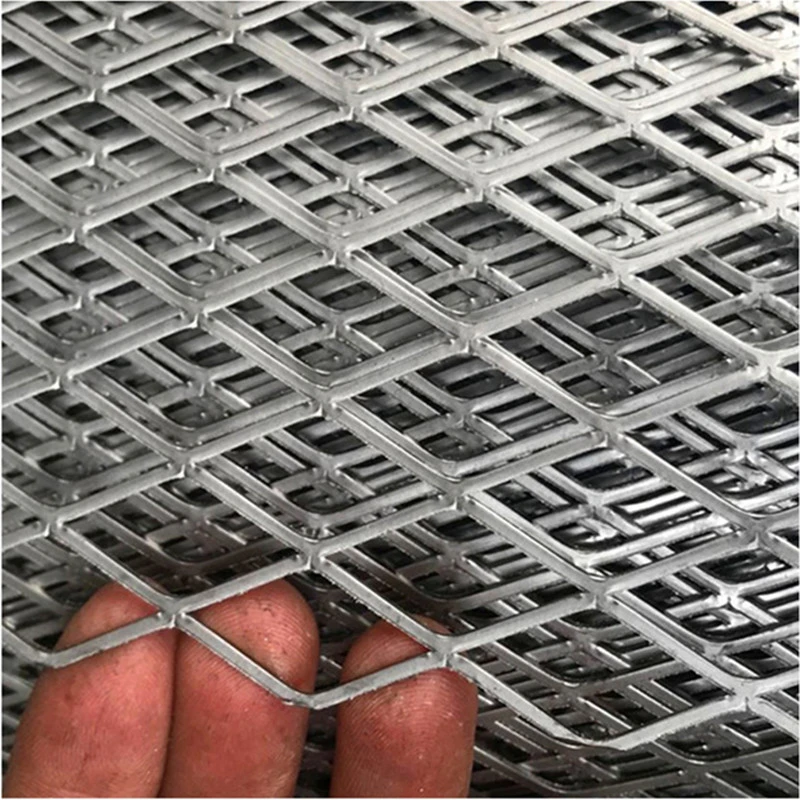

2. Material Selection The choice of material is critical when it comes to metal scaffolding planks. Aluminum and steel are commonly used due to their strength and durability. Verify that the manufacturer uses high-grade materials that resist corrosion and can withstand heavy loads without bending or breaking.

3. Customization Options Every construction project is unique, and having customized solutions can be beneficial. A good manufacturer should offer a range of sizes, widths, and finishes to cater to specific project needs. They should also be open to working with clients to develop tailored solutions.

4. Manufacturing Capabilities Consider the manufacturing capabilities of the supplier. A well-equipped facility with modern machinery can produce high-quality products efficiently. Additionally, assess the production capacity to ensure they can meet your volume requirements on time.

5. Reputation and Experience Research the manufacturer’s background and reputation in the industry. Look for reviews, testimonials, and case studies that showcase their experience and reliability. A manufacturer with years of experience is more likely to understand the nuances of the construction industry and client expectations.

wholesale scaffolding metal plank manufacturer

6. Customer Support and Service Excellent customer service is a hallmark of a quality manufacturer. They should provide clear communication, timely responses to inquiries, and assistance in resolving any issues that may arise. Strong after-sales support is equally important to address any concerns post-purchase.

Benefits of Using High-Quality Metal Planks

Investing in high-quality metal planks brings numerous advantages

- Enhanced Safety Superior metal planks offer increased structural integrity, reducing the risk of accidents on-site. Workers can trust that their platform is sturdy and reliable, which enhances overall job site safety.

- Durability and Longevity Quality materials resist wear and tear, providing a longer lifespan for the planks. This means fewer replacements over time, which can lead to significant cost savings for construction companies.

- Increased Productivity Well-manufactured scaffolding systems allow workers to move efficiently, reducing delays associated with poor-quality equipment. A reliable platform encourages workers to perform their tasks more confidently and quickly.

- Compliance with Regulations Quality manufacturers ensure their products adhere to local and international standards. This compliance protects construction companies from legal liabilities and helps maintain a positive reputation in the industry.

Conclusion

Choosing the right wholesale scaffolding metal plank manufacturer is a critical decision that directly impacts project safety, efficiency, and cost-effectiveness. By considering factors such as quality assurance, material selection, customization options, and reputation, construction companies can align themselves with producers who meet their specific needs. In turn, utilizing high-quality metal planks can enhance workplace safety, boost productivity, and foster a successful project outcome. Investing in the right scaffolding solutions is not just a matter of preference but a vital step toward ensuring a safe and efficient working environment.

-

Smart Warehouse Management System-Example Corp|Inventory Control&Operational Efficiency

NewsJul.13,2025

-

SmartFlow™ Series-ExampleCorp|Real-Time Monitoring&Energy Efficiency

NewsJul.13,2025

-

Powder Coated Galvanized Welded Wire Mesh Fence - Xuzhou Metal|Corrosion-Resistant Fencing,Durable Industrial Solutions

NewsJul.13,2025

-

Steel Expanded Metal Mesh Fence-Durable Industrial Fencing|Corrosion-Resistant, Customizable

NewsJul.13,2025

-

SmartFlow 3000: Industrial Automation Solutions by InnovateTech | Precision, Efficiency, AI-driven Optimization

NewsJul.13,2025

-

Hop Dipped Galvanized Fence - Xuzhou Metal Products|Durable Temporary Fencing&Construction Site Security

NewsJul.13,2025