ઓગસ્ટ . 15, 2024 17:59 Back to list

Exploring the Innovative Designs and Manufacturing Processes of Wire Mesh Production Facilities Worldwide

Understanding Wire Mesh Factories An Overview of Their Importance and Operations

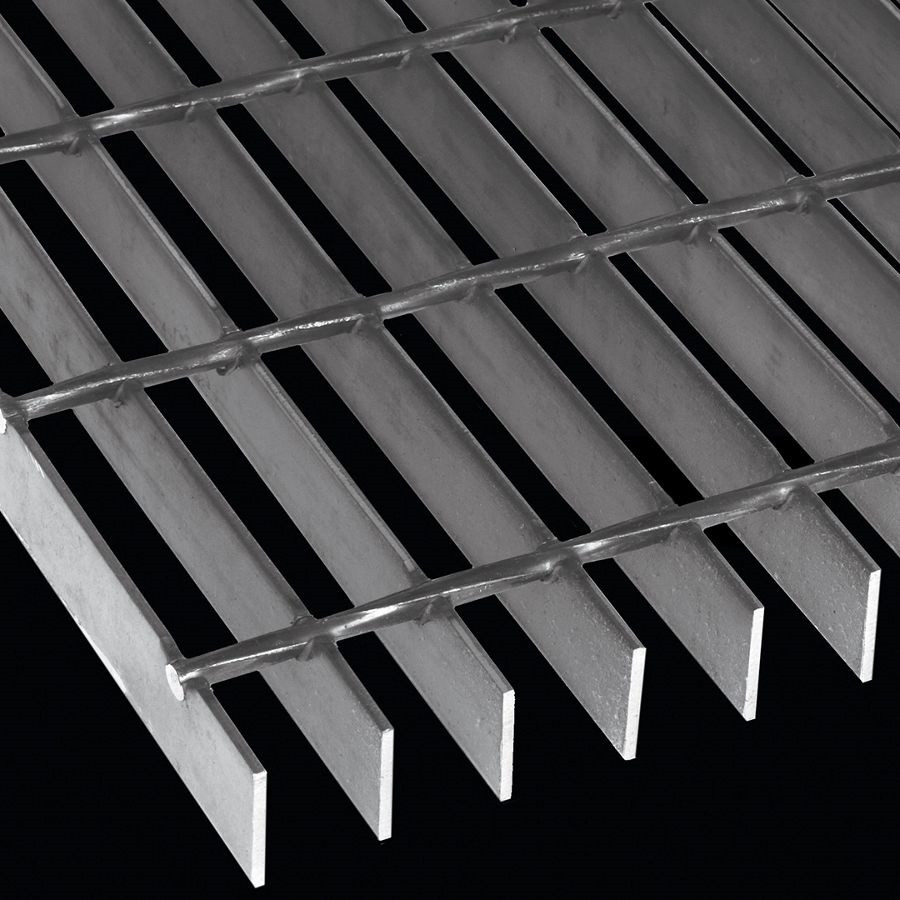

Wire mesh is an incredibly versatile product utilized in a multitude of industries including construction, manufacturing, agriculture, and even mining. Wire mesh factories specialize in the production of this essential material, which is made from interwoven wires and can vary in size, shape, and material composition. This article aims to delve into the operations of wire mesh factories, their significance in various sectors, and the broader implications of their products in today’s economy.

At the heart of every wire mesh factory is the process of wire drawing and weaving. The production starts with raw materials, typically steel or stainless steel, which are drawn into thin wires. This initial process is crucial as it determines the tensile strength and flexibility of the final product. Once wires are produced, they are woven into mesh using various patterns such as square, rectangular, and hexagonal openings. This weaving can be done either manually or through automated machines, depending on the scale of production and the specific requirements of the end product.

The role of wire mesh in diverse applications cannot be overstated. In construction engineering, wire mesh is often used for concrete reinforcement, providing the necessary support to withstand heavy loads. In agriculture, it serves as fencing material to protect crops from pests and wildlife. The manufacturing sector also employs wire mesh for filtration, separation, and as components in machinery. Additionally, wire mesh is prevalent in mining, where it is used for sifting and sorting materials. Each application requires a different specification of wire mesh, which highlights the importance of customization in a factory’s production process.

Moreover, the significance of wire mesh extends beyond its practical applications. Wire mesh factories play a critical role in supporting the economy by providing jobs and fostering local industries. The manufacturing process often involves a skilled workforce that is trained in the nuances of production and quality control. Furthermore, these factories typically source raw materials locally, which helps stimulate regional economies.

wire mesh factories

In recent years, the demand for wire mesh has increased due to growth in infrastructure development and advancements in industrial applications. This surge has prompted many wire mesh factories to adopt innovative technologies and techniques in their production processes. Automation, for instance, has improved efficiency and accuracy, allowing for higher volume outputs and reduced labor costs. Additionally, sustainability has become a focal point for many factories, with efforts to recycle materials and reduce waste during production.

Quality control is another significant aspect of wire mesh manufacturing. Factories implement rigorous testing procedures to ensure that the wire mesh meets industry standards and customer specifications. This is particularly crucial in sectors like construction, where the integrity of materials can directly impact safety. Regular inspections and adherence to international standards help factories maintain their reputation and competitive edge in the market.

As we look to the future, the evolution of wire mesh factories will likely continue to be influenced by technological advancements and changing market demands. The integration of smart manufacturing practices that utilize data analytics and the Internet of Things (IoT) could further enhance production capabilities. Moreover, as the emphasis on sustainable practices grows globally, wire mesh factories will need to adapt by implementing greener processes and sustainably sourced materials.

In conclusion, wire mesh factories play an indispensable role in the modern economy, providing essential products across a variety of sectors. Their operations not only contribute to the structural integrity of countless projects but also support economic growth and innovation. As technology progresses, the future of wire mesh manufacturing holds promise for enhanced efficiency, sustainability, and continued relevance in a fast-paced industrial landscape.

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025

-

Galvanized Iron Wire Anti Mosquito Window Screen Net | Durable

NewsAug.03,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing Solutions&Customizable Construction Site Security

NewsAug.02,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

NewsAug.02,2025