Sep . 22, 2025 11:45 Back to list

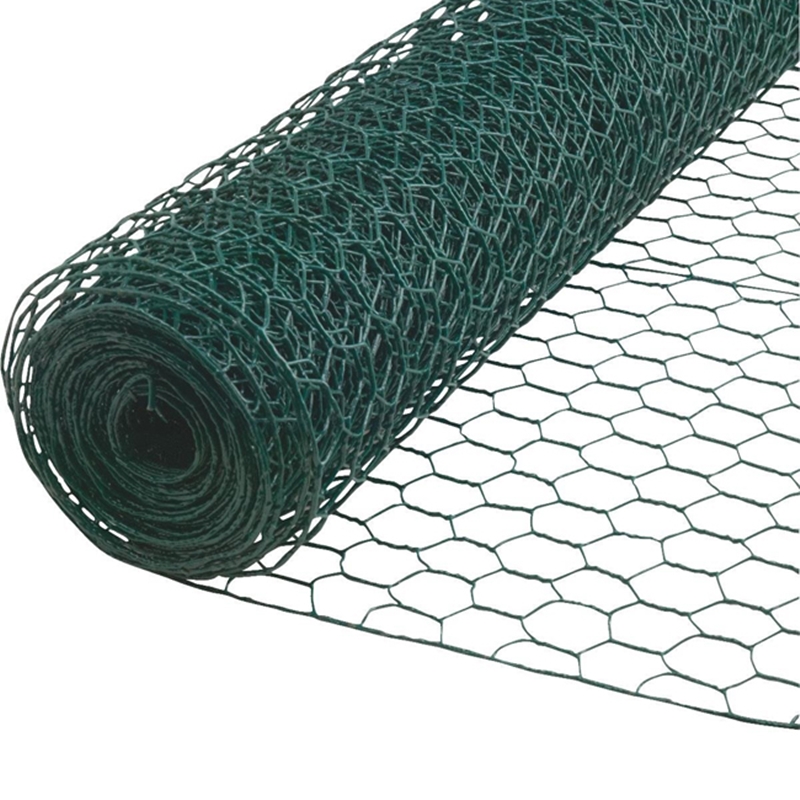

Strong Double Twisted Hexagonal Gabion Mesh Roll for Erosion Control

Industry Trends and the Role of Gabion Mesh

The global demand for resilient and environmentally sustainable civil engineering solutions continues to escalate, driven by factors such as climate change, increasing urbanization, and the need for robust infrastructure development. Erosion control, land stabilization, and hydraulic engineering are critical areas experiencing rapid innovation. Within this landscape, gabion structures have long proven their efficacy, with modern manufacturing advancements enhancing their performance and application versatility. A cornerstone of these solutions is the Double Twisted Hexagonal Gabion Mesh Roll, a fundamental material for constructing flexible, permeable, and monolithic structures.

Current industry trends emphasize materials that offer superior longevity, minimal environmental impact, and cost-effectiveness over their lifecycle. Engineers and project managers are increasingly specifying solutions that can withstand extreme weather events, resist corrosion in aggressive environments, and integrate seamlessly with natural landscapes. The inherent characteristics of double twisted hexagonal gabion mesh—including its flexibility, strength, and ability to adapt to ground movement—position it as an indispensable component in contemporary engineering projects ranging from highway embankments to complex river training works.

Manufacturing Process Flow and Quality Assurance

The production of a high-quality Double Twisted Hexagonal Gabion Mesh Roll is a meticulously controlled process, ensuring the final product meets stringent international standards for strength, durability, and corrosion resistance. Our manufacturing process integrates advanced technology with rigorous quality control at every stage.

Key Stages of Production:

- 1. Raw Material Sourcing & Preparation:

High-grade low-carbon steel wire (typically 2.2 mm to 4.0 mm diameter) is sourced, meeting specific tensile strength requirements (e.g., 38-55 kg/mm² or 380-550 N/mm²) and elongation at break (minimum 10%). This ensures the wire can withstand the double-twisting process without fracturing and provides adequate long-term structural integrity. For enhanced corrosion resistance, wires are galvanized with a heavy zinc coating (typically ≥ 245 g/m² for ASTM A641/A975 standards), or further coated with a PVC layer (minimum 0.5 mm thickness) over the galvanized wire, specifically for highly corrosive environments.

- 2. Double Twisting Weaving:

The galvanized or PVC-coated wires are fed into specialized gabion weaving machines. These machines create a double-twist hexagonal mesh pattern, where adjacent wires are twisted at least twice around each other. This crucial double-twist mechanism prevents unraveling should a wire break, thereby maintaining the mesh's structural integrity, a critical advantage over single-twist meshes. Standard mesh apertures include 60x80 mm, 80x100 mm, 100x120 mm, and 120x150 mm.

- 3. Edge Reinforcement (Selvage Wires):

Heavier diameter wires, known as selvage wires, are machine-woven along the edges of the mesh panels. These selvage wires provide essential reinforcement, enhancing the tensile strength and overall stability of the gabion structure, particularly when lifting or during installation. The diameter of the selvage wire is typically 0.5 mm to 1.0 mm thicker than the mesh wire.

- 4. Rolling & Packaging:

The finished mesh is then expertly rolled into compact rolls for efficient transportation and storage. Each roll is securely bound and labeled with product specifications to ensure traceability and ease of identification on-site.

Quality Control & Testing Standards:

Our products adhere to rigorous international testing standards, including but not limited to ISO 9001:2015 for quality management systems, ASTM A975-11 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses), and EN 10223-3 (Steel wire and wire products for fencing and netting – Part 3: Hexagonal steel netting for civil engineering purposes). Each batch undergoes comprehensive testing for:

- Wire Diameter Tolerance.

- Zinc Coating Mass and Adhesion (blade test).

- PVC Coating Thickness and Adhesion.

- Tensile Strength and Elongation of Wire.

- Mesh Aperture Dimensions.

- Resistance to Unraveling (panel strength test).

These stringent controls ensure a service life typically exceeding 50 years for heavily galvanized and PVC-coated gabion mesh in benign environments, and 15-25 years even in challenging marine or highly acidic conditions. Target industries include civil engineering, hydraulic works, coastal protection, mining, land reclamation, and infrastructure development (roads, railways).

Technical Specifications and Performance Data

Understanding the precise technical parameters of a Double Twisted Hexagonal Gabion Mesh Roll is crucial for engineering design and material selection. Our products are engineered to deliver consistent performance under various environmental and load conditions.

Standard Product Specifications:

These specifications underscore the robust engineering behind each roll, ensuring reliability and performance for diverse civil and environmental applications.

Application Scenarios and Technical Advantages

The versatility and inherent engineering benefits of a Double Twisted Hexagonal Gabion Mesh Roll make it an ideal choice across a wide spectrum of demanding applications. Its unique properties provide significant technical advantages over traditional rigid structures.

Typical Application Scenarios:

- Retaining Walls and Embankments: Used to construct gravity retaining walls, reinforced soil walls, and to stabilize critical embankments for roads, railways, and bridges. Their flexibility allows them to settle and deform without structural failure.

- River Training and Canal Linings: Essential for preventing scour and erosion along riverbanks, canal linings, and overflow structures. The permeable nature of gabions dissipates hydraulic energy, reducing erosive forces.

- Erosion Control and Slope Protection: Widely deployed on steep slopes susceptible to erosion, offering immediate stabilization and fostering vegetative growth that further enhances soil retention.

- Coastal and Marine Protection: PVC-coated gabions are particularly effective in saltwater environments, protecting shorelines, jetties, and breakwaters from tidal and wave erosion due to their exceptional corrosion resistance.

- Culvert Headwalls and Outlet Structures: Providing durable and flexible solutions for protecting culvert inlets and outlets from scour and collapse.

- Mining and Land Reclamation: Stabilizing slopes in open-pit mines, constructing waste containment structures, and facilitating land reclamation projects.

Key Technical Advantages:

- Flexibility and Adaptability: Gabion structures can tolerate differential settlement without loss of structural integrity, adapting to ground movement unlike rigid concrete structures. This is crucial in areas with unstable soils or seismic activity.

- Permeability: The inherent permeability of gabion walls allows for free drainage of water, eliminating hydrostatic pressure buildup behind the structure. This significantly reduces the risk of structural failure and makes them ideal for hydraulic applications.

- Durability and Longevity: High-quality galvanized and PVC-coated wires provide excellent resistance to corrosion, abrasion, and weathering, ensuring a long design life with minimal maintenance.

- Environmental Integration: Gabion structures blend naturally with the environment, and over time, vegetation can grow through the rock fill, enhancing aesthetic appeal and ecological value. This promotes energy saving by reducing the need for costly conventional landscaping and repair work.

- Cost-Effectiveness: Utilizing locally available fill material (rocks, stone) significantly reduces transportation costs. The ease of construction and minimal requirement for specialized equipment contribute to lower overall project expenses compared to concrete or masonry alternatives.

- Structural Stability: When filled with stone, the gabion units form a monolithic, heavy, and stable structure capable of resisting significant earth pressures and hydraulic forces. The double-twisted mesh ensures that localized wire breaks do not lead to catastrophic structural unraveling.

Vendor Comparison and Customized Solutions

When selecting a supplier for Double Twisted Hexagonal Gabion Mesh Roll, discerning buyers in the B2B sector must evaluate beyond mere price. Factors such as product quality, manufacturing certifications, capacity for customization, technical support, and logistical efficiency are paramount. A strategic partnership with a reliable vendor can significantly impact project success, budget, and long-term performance.

Key Factors for Vendor Comparison:

- Certifications and Compliance: Verify adherence to international standards like ISO 9001, ASTM A975, and EN 10223-3. These certifications indicate a commitment to quality management and product performance.

- Material Quality and Coatings: Assess the grade of steel wire, zinc coating weight, and PVC coating thickness. Superior materials ensure extended service life and corrosion resistance.

- Manufacturing Expertise: Look for vendors with extensive experience and state-of-the-art manufacturing facilities, ensuring consistent product quality and efficient production capabilities.

- Customization Capabilities: The ability to provide bespoke mesh sizes, wire diameters, and coating options tailored to specific project requirements is a significant advantage.

- Technical Support and Engineering Assistance: A reputable vendor offers pre-sales consultation, design guidance, and post-sales support to ensure optimal product application.

- Lead Time and Logistics: Efficient production schedules and reliable global logistics are crucial for meeting project deadlines and minimizing supply chain disruptions.

Customized Solutions:

We understand that every project presents unique challenges. Our engineering team specializes in developing customized Double Twisted Hexagonal Gabion Mesh Roll solutions to meet precise design specifications. This includes:

- Variable Mesh Apertures: Production of non-standard mesh sizes (e.g., smaller for finer sediment retention or larger for reduced material cost where applicable).

- Specific Wire Diameters: Tailoring mesh and selvage wire diameters to accommodate specific tensile strength requirements or project longevity demands.

- Enhanced Coating Options: Providing thicker PVC coatings, specialized polymer coatings, or even Galfan (zinc-aluminum alloy) coatings for extreme corrosive environments beyond standard galvanization.

- Roll Dimensions: Manufacturing rolls in custom widths and lengths to minimize waste and optimize installation efficiency for large-scale projects.

Our commitment to flexibility ensures that our products seamlessly integrate into diverse project designs, offering optimal performance and cost-efficiency.

Application Case Studies

The practical deployment of Double Twisted Hexagonal Gabion Mesh Roll demonstrates its effectiveness and adaptability in real-world scenarios. Our solutions have been instrumental in a multitude of critical infrastructure and environmental protection projects globally.

Case Study 1: Riverbank Stabilization Project, Southeast Asia

A major river in Southeast Asia, prone to severe seasonal flooding and erosion, required urgent stabilization. Traditional concrete solutions were deemed too rigid and environmentally impactful. Our team supplied galvanized and PVC-coated gabion mesh rolls (80x100mm mesh, 2.7mm wire diameter, 0.5mm PVC coating) for the construction of extensive gabion retaining walls and river mattress systems. The project spanned 5 kilometers of riverbank. The gabions allowed for natural vegetation growth, promoting ecological restoration while effectively mitigating erosion and scour during subsequent flood events. The flexibility of the structures successfully accommodated minor ground settlements without failure, proving its resilience in a dynamic fluvial environment. This project highlighted the long-term corrosion resistance in humid, tropical conditions.

Case Study 2: Highway Embankment Reinforcement, Mountainous Region

In a challenging mountainous terrain, a new highway construction faced issues with unstable cut and fill embankments. Geotechnical engineers opted for gabion retaining walls to provide structural support and prevent landslides. We provided heavy-duty galvanized gabion mesh rolls (100x120mm mesh, 3.4mm wire diameter) designed for high tensile strength. Over 2,000 cubic meters of locally sourced stone were used as fill. The project's success was attributed to the rapid installation capabilities, significantly reducing construction time and costs. The permeable nature of the gabion walls effectively managed subsurface water drainage, a critical factor in preventing slope failures in the region. Post-construction monitoring confirmed excellent stability and minimal deformation over five years of service.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ):

Q: What is the primary advantage of double twisted mesh over single twisted mesh?

A: The double-twist mechanism ensures that if a single wire breaks, the mesh retains its integrity, preventing unraveling. This enhances the overall structural stability and longevity of the gabion unit, especially under dynamic loading conditions.

Q: How do I choose between galvanized and PVC-coated gabion mesh?

A: Heavily galvanized mesh is suitable for most freshwater and terrestrial applications. For aggressive environments such as saltwater, highly acidic or alkaline soils, or heavily polluted areas, PVC-coated Double Twisted Hexagonal Gabion Mesh Roll provides an additional layer of protection and significantly extends the service life.

Q: Is specific equipment required for installing gabion mesh rolls?

A: While basic hand tools (pliers, tie wire tools) are sufficient for assembly, for large-scale projects, machinery for rock placement (e.g., excavators with specialized attachments) can significantly speed up the filling process. The mesh itself is flexible and can be manipulated by hand, then formed into baskets or mattresses.

Lead Time and Fulfillment:

Our typical lead time for standard Double Twisted Hexagonal Gabion Mesh Roll orders is 2-4 weeks, depending on order volume and current production schedules. For large-scale or customized orders, lead times will be confirmed upon quotation. We maintain a robust inventory of raw materials and operate advanced production lines to ensure timely fulfillment. We offer flexible shipping options, including sea freight, rail, and road, tailored to project location and urgency. All products are meticulously packaged to prevent damage during transit.

Warranty Commitments:

We stand behind the quality of our products. All heavily galvanized gabion mesh rolls come with a standard 10-year warranty against manufacturing defects and premature corrosion under normal environmental conditions. PVC-coated gabion mesh rolls carry an extended warranty of 20 years, reflecting their enhanced resistance to aggressive environments. Specific warranty terms and conditions are provided with each order and are subject to proper installation and maintenance as per industry best practices.

Customer Support Information:

Our dedicated technical support team is available to assist you from project inception through completion. We offer:

- Pre-sales consultation and material selection guidance.

- Technical data sheets and installation manuals.

- Post-sales support for any product-related inquiries.

- Assistance with custom product development.

Contact us via phone or email for expert advice and reliable service. Your project's success is our priority.

References

- ASTM International. (2011). ASTM A975-11: Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses. West Conshohocken, PA: ASTM International.

- ISO. (2015). ISO 9001:2015: Quality management systems – Requirements. Geneva, Switzerland: International Organization for Standardization.

- Maccaferri. (2016). Gabion and Reno Mattress Technical Guide. Retrieved from [example_geotechnical_engineering_journal.org].

- C.R.I. Clayton, L.W. Davies, & J.C. Miles. (2001). The Performance of Gabion Retaining Walls. CIRIA C516. London, UK: Construction Industry Research and Information Association.

- US Army Corps of Engineers. (1989). EM 1110-2-1601: Hydraulic Design of Flood Control Channels. Washington, D.C.: Department of the Army.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025