Aug . 24, 2025 00:20 Back to list

Construction Rebar Welded Mesh | Strong, Durable Concrete Reinforcement

Introduction to Advanced Reinforcement Solutions

In the modern construction landscape, efficiency, structural integrity, and long-term durability are paramount. Traditional methods of cutting and tying individual reinforcing bars on-site are increasingly being superseded by advanced, factory-fabricated solutions. Among these, Construction Reinforced Steel Bar Welded Wire Mesh stands out as a critical innovation. This engineered product significantly streamlines the reinforcement process, offering superior quality control, accelerated project timelines, and optimized material usage. Designed for diverse applications ranging from concrete slabs and foundations to precast elements and road construction, its adoption marks a clear shift towards more industrialized and reliable building practices. This comprehensive article delves into the technical facets, application advantages, and market dynamics surrounding this indispensable construction material, providing B2B decision-makers and engineering professionals with the insights needed to leverage its full potential.

Industry Trends and Market Dynamics in Reinforcement

The global construction sector is undergoing significant transformation, driven by demands for faster project completion, enhanced safety standards, and sustainable building practices. A key trend is the increasing preference for pre-fabricated and engineered reinforcement solutions over traditional, labor-intensive methods. This shift is fueled by several factors:

- Automation and Robotics: Advances in manufacturing automation allow for precise fabrication of welded wire mesh, minimizing human error and ensuring consistent quality. This directly translates into reliable structural performance and reduced on-site inspection complexities.

- Sustainability Initiatives: Optimized material usage, reduced waste, and the potential for using recycled steel in welded wire mesh contribute to greener construction practices. Furthermore, faster installation times lead to lower overall project emissions.

- Enhanced Structural Codes: Stricter building codes and engineering standards worldwide demand reinforcement materials with predictable performance characteristics, particularly concerning tensile strength, yield strength, and weld shear strength, which welded wire mesh rigorously meets under controlled factory conditions.

- Labor Shortages and Cost Pressures: The construction industry faces persistent labor shortages. Pre-fabricated reinforcement significantly reduces on-site labor requirements, mitigating these challenges and offering substantial cost savings in overall project expenditure.

These trends collectively position engineered solutions like welded wire mesh as indispensable for future infrastructure and building development, underscoring its pivotal role in modern construction methodologies.

Manufacturing Process: Precision and Quality Assurance

The manufacturing of Construction Reinforced Steel Bar Welded Wire Mesh is a highly automated and precise process, ensuring consistent product quality that surpasses manual fabrication. The process begins with carefully selected raw materials, typically high-strength deformed or plain steel bars compliant with international standards such as ASTM A615/A706 or BS 4449. The transformation into finished mesh involves several critical stages:

Process Flow Overview:

- Raw Material Procurement & Inspection: High-grade steel wire rods or bars are sourced and undergo rigorous inspection for chemical composition, mechanical properties (tensile strength, yield strength), and surface integrity to ensure compliance with relevant material specifications.

- Straightening & Cutting: The steel bars are fed into automated machines that straighten them and cut them to precise lengths according to the required mesh dimensions. This step minimizes material waste and ensures dimensional accuracy.

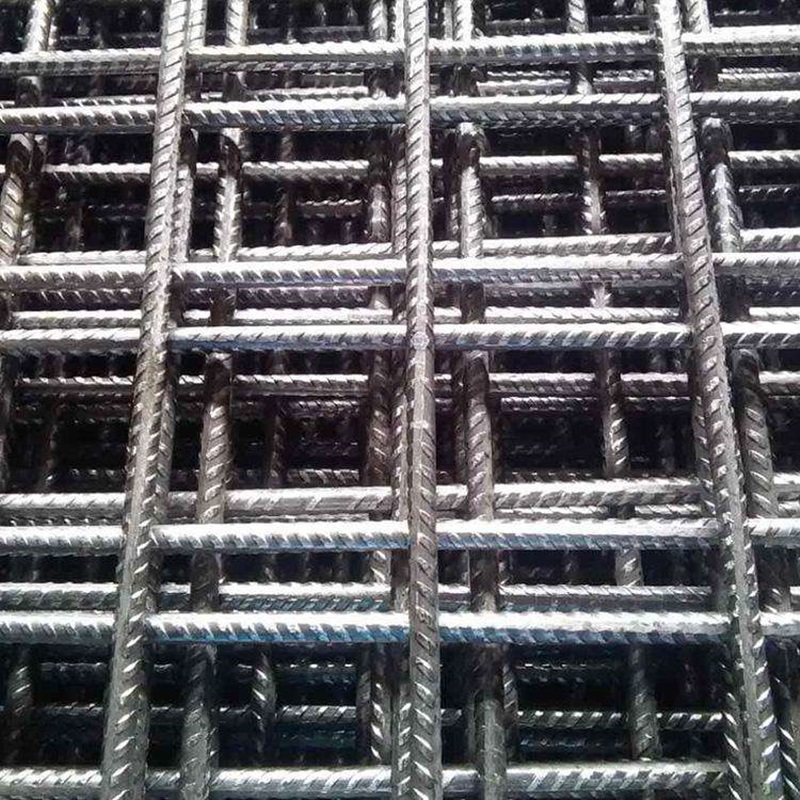

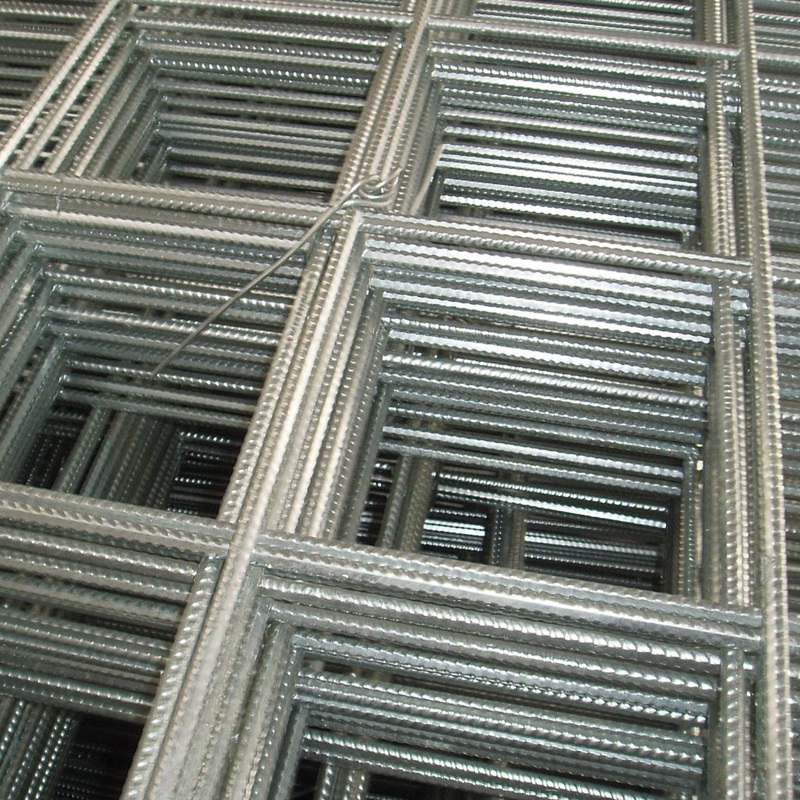

- Automated Resistance Welding: Longitudinal and transverse bars are precisely positioned perpendicular to each other. High-current, low-voltage resistance welding electrodes then apply pressure and heat at each intersection, forming a fusion weld. This automated process ensures uniform weld strength and consistent mesh geometry across the entire sheet.

- Quality Control & Testing: Throughout the production, continuous quality checks are performed. This includes visual inspection, dimensional checks (bar spacing, overall sheet size), and destructive testing of weld shear strength (e.g., in accordance with ASTM A1064/A1064M). Manufacturers also adhere to ISO 9001 quality management systems.

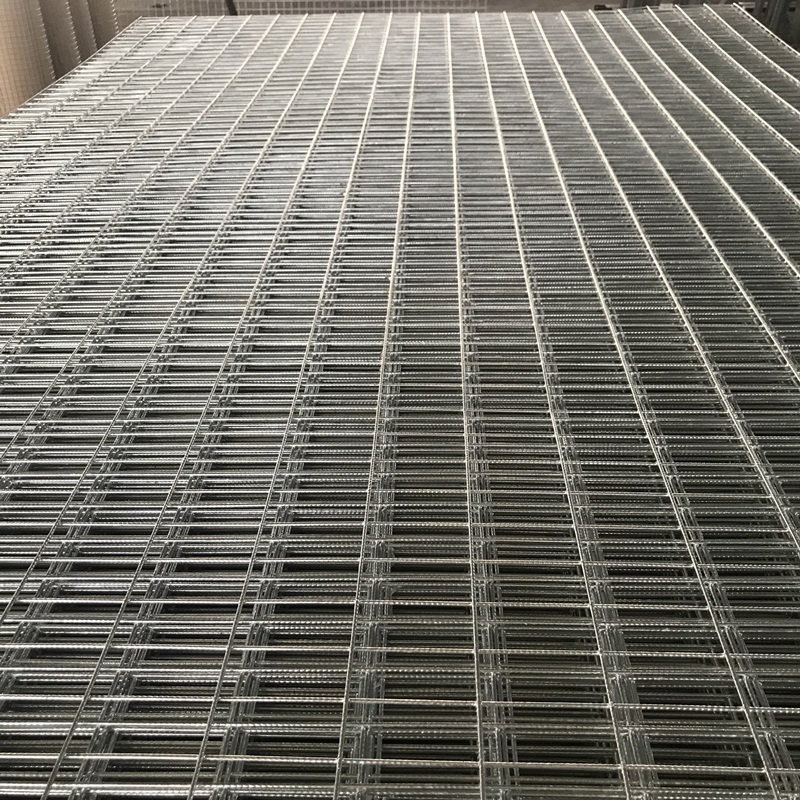

- Finishing & Packaging: Once verified, the mesh sheets are bundled, labeled, and prepared for dispatch. Options for galvanized or epoxy-coated mesh for enhanced corrosion resistance are also available depending on project specifications.

This stringent manufacturing process ensures that the finished product boasts a service life comparable to the concrete structure itself, often exceeding 50-100 years under normal conditions, particularly when used in target industries such as civil infrastructure (roads, bridges), industrial construction (foundations, heavy-duty slabs), and precast concrete manufacturing.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of Construction Reinforced Steel Bar Welded Wire Mesh is crucial for engineers and procurement specialists. These parameters define the material's structural contribution and compliance with design requirements. Key specifications include:

- Bar Diameter: Ranging typically from 4mm to 16mm (and larger for heavy-duty applications), influencing tensile strength and load-bearing capacity.

- Mesh Spacing: The center-to-center distance between longitudinal and transverse bars, determining the effective reinforcing area per unit of concrete. Common spacings include 100x100mm, 150x150mm, 200x200mm, or customized non-square patterns.

- Sheet Dimensions: Standard panels are available in various widths and lengths (e.g., 2.4m x 4.8m, 3m x 6m), optimizing for common construction elements and minimizing cuts.

- Material Grade: High-tensile steel, typically conforming to ASTM A615 Grade 60 (420 MPa yield strength) or equivalent international standards (e.g., BS 4449 Grade 500).

- Weld Shear Strength: A critical parameter confirming the integrity of each intersection, often specified as a percentage of the bar's yield strength (e.g., 50-70% for smooth wires, higher for deformed bars).

Typical Product Specification Table

| Parameter | Typical Range / Value | Standard (Example) |

|---|---|---|

| Bar Diameter (Longitudinal) | 5 mm - 12 mm | ASTM A615/A706, BS 4449 |

| Bar Diameter (Transverse) | 5 mm - 12 mm | ASTM A615/A706, BS 4449 |

| Mesh Spacing (L x T) | 100x100mm to 300x300mm | ASTM A1064, AS/NZS 4671 |

| Sheet Dimensions | Up to 3m x 6m (Customizable) | Industry Standard |

| Yield Strength (min) | 420 MPa (Grade 60) | ASTM A615/A706 |

| Tensile Strength (min) | 600 MPa (Grade 60) | ASTM A615/A706 |

| Weld Shear Strength | Min. 345 MPa (on smaller bar) | ASTM A1064 |

These specifications allow engineers to perform accurate structural calculations, ensuring the designed concrete elements meet required load capacities and serviceability limits. The uniform spacing and robust welds provided by factory-made mesh enhance concrete crack control and load distribution compared to manually tied rebar.

Application Scenarios and Industry Benefits

The versatility and inherent advantages of Construction Reinforced Steel Bar Welded Wire Mesh make it an ideal choice across a broad spectrum of construction applications. Its ease of handling and placement significantly accelerates project timelines, offering substantial value to diverse sectors:

Key Application Areas:

- Roads and Highways: Used extensively in concrete pavements for highways, airport runways, and bridge decks, where it helps control shrinkage cracking and distributes wheel loads efficiently, prolonging pavement life.

- Building Foundations and Slabs: Provides primary and secondary reinforcement in ground slabs, raft foundations, and suspended slabs, improving flexural strength and preventing temperature-induced cracking.

- Precast Concrete Elements: Essential for reinforcing precast walls, panels, beams, and columns, where its precise dimensions and consistent quality are critical for automated production lines and structural performance.

- Water Supply & Drainage Infrastructure: Utilized in concrete reservoirs, water treatment plant structures, culverts, and large-diameter pipes, where corrosion resistance (with appropriate coatings) and crack control are vital for long-term service.

- Industrial and Commercial Floors: For heavy-duty industrial floors and warehouse slabs, the mesh provides robust reinforcement against heavy loads, impacts, and abrasive wear, ensuring longevity and minimal maintenance.

- Tunnel Linings and Retaining Walls: In demanding geotechnical applications, it contributes to the stability and durability of concrete linings and structural walls.

In each of these scenarios, the inherent advantages such as energy saving through reduced on-site labor and machinery use, and enhanced structural performance due to superior bond and uniform stress distribution, make welded wire mesh a preferred reinforcement solution. For instance, in petrochemical facilities, where foundations must withstand significant dynamic loads and aggressive environments, precisely engineered mesh ensures the structural integrity and longevity required, demonstrating excellent resistance to stress concentrations.

Technical Advantages and Competitive Edge

The technical superiority of Construction Reinforced Steel Bar Welded Wire Mesh provides a significant competitive edge over traditional rebar tying methods. This engineered approach to reinforcement offers tangible benefits across multiple project facets:

- Precision and Uniformity: Factory-controlled production ensures exact bar spacing and consistent weld strength at every intersection. This eliminates the variability inherent in manual tying, leading to more predictable structural performance and optimal concrete-to-steel bond.

- Accelerated Installation: Large sheets of mesh are significantly faster to lay than individual rebar components. This drastically reduces on-site labor time and costs, directly translating into shorter project schedules and earlier project completion.

- Reduced Material Waste: Optimized mesh design and factory cutting minimize scrap materials. This not only lowers material procurement costs but also contributes to site cleanliness and environmental sustainability.

- Enhanced Structural Integrity: The robust fusion welds at each intersection prevent bar displacement during concrete pouring and vibration, ensuring the reinforcement remains in its designed position. This contributes to superior shear resistance and overall structural stability.

- Improved Safety: Fewer manual handling tasks and reduced on-site cutting and tying operations decrease the risk of workplace injuries, fostering a safer construction environment.

- Cost-Effectiveness: While the initial unit cost might be comparable to loose rebar, the significant savings in labor, installation time, and reduced waste translate into a lower overall installed cost, making it a highly economical choice for large-scale projects.

These advantages collectively position welded wire mesh as a superior, modern reinforcement solution that aligns with the lean construction principles of efficiency, quality, and economic viability.

Vendor Comparison and Selection Criteria

Choosing the right supplier for Construction Reinforced Steel Bar Welded Wire Mesh is a critical decision that impacts project quality, budget, and timeline. A comprehensive vendor comparison should evaluate several key criteria beyond just the unit price:

Key Vendor Selection Criteria:

- Quality Certifications: Verify adherence to international standards like ISO 9001, and product-specific certifications (e.g., ASTM, BS, DIN, JIS) ensuring material integrity and consistent manufacturing processes.

- Customization Capabilities: Assess the ability to produce mesh with specific bar diameters, spacing, and sheet dimensions tailored to unique project requirements.

- Lead Time and Delivery Reliability: Evaluate the supplier's production capacity and logistics capabilities to meet project schedules, especially for large or time-sensitive orders.

- Technical Support and Expertise: A knowledgeable supplier can offer valuable engineering support, optimizing mesh design for specific applications and assisting with compliance.

- References and Reputation: Inquire about past projects and client testimonials to gauge reliability and customer satisfaction. Long-standing partnerships with reputable construction firms are a strong indicator of trustworthiness.

- After-Sales Service and Warranty: Understand the warranty terms and the level of support provided post-purchase, including handling of potential issues or additional requirements.

Supplier Comparison Table (Illustrative)

| Feature | Supplier A (Regional) | Supplier B (International) | Our Company (Global/Premium) |

|---|---|---|---|

| Quality Certifications | ISO 9001:2015 | ISO 9001:2015, ASTM A1064 | ISO 9001:2015, ASTM A1064, BS 4483, AS/NZS 4671 |

| Customization Range | Limited standard sizes | Moderate, with lead time | Extensive, optimized engineering |

| Lead Time (Typical) | 2-3 weeks | 1-2 weeks | 5-10 business days (expedited available) |

| Technical Support | Basic product information | Application guidance | Dedicated engineering consultations, design optimization |

| Geographic Reach | Local/Regional | National/Some International | Global Distribution Network |

Customized Solutions and Project Tailoring

While standard mesh panels cater to many applications, complex or large-scale projects often benefit immensely from customized reinforcement solutions. Leading manufacturers understand that 'one size fits all' rarely applies to intricate engineering designs. Customization capabilities for Construction Reinforced Steel Bar Welded Wire Mesh include:

- Varying Bar Diameters and Spacing: Tailoring longitudinal and transverse bar diameters and their spacing to precisely match specific load requirements and design specifications, minimizing over-reinforcement and material waste.

- Irregular Panel Shapes and Sizes: Manufacturing mesh panels in non-rectangular shapes or specialized dimensions to fit unique structural geometries, reducing on-site cutting and speeding up installation.

- Special Coatings: Providing galvanized or epoxy-coated mesh for projects requiring enhanced corrosion resistance, particularly in aggressive environments (e.g., coastal areas, chemical plants, wastewater treatment facilities).

- Design Optimization: Collaborating with project engineers to perform value engineering, where the mesh configuration is optimized using advanced software (e.g., finite element analysis - FEA) to achieve desired structural performance with the most efficient material use.

- Pre-fabricated Elements: Supplying pre-cut and pre-bent mesh elements that integrate directly into precast concrete forms or complex on-site pours, further streamlining construction.

These customized offerings ensure that the reinforcement precisely meets the structural demands of each unique project, leading to superior performance, significant cost savings, and accelerated project delivery by minimizing on-site modifications and waste. Our company specializes in delivering bespoke solutions, working closely with clients from concept to completion.

Real-World Application Case Studies

The tangible benefits of using Construction Reinforced Steel Bar Welded Wire Mesh are best illustrated through real-world applications. These case studies highlight how engineered reinforcement solutions translate into successful project outcomes, satisfying stringent client requirements and delivering long-term value:

Case Study 1: Major Highway Expansion Project

A large-scale highway expansion required the rapid construction of concrete pavements for several kilometers. Our client, a leading infrastructure contractor, needed a reinforcement solution that could be installed quickly to meet aggressive timelines while ensuring long-term durability against heavy traffic loads. We supplied custom-designed mesh panels with specific bar diameters and spacing to optimize crack control and load distribution. The contractor reported a 35% reduction in reinforcement installation time compared to traditional rebar methods, significantly contributing to the project's early completion and reducing overall labor costs. The uniformity of the mesh also led to a more consistent concrete cover, enhancing the pavement's service life.

Case Study 2: Industrial Warehouse Flooring

An industrial client required a highly durable concrete floor for a new logistics warehouse, capable of withstanding constant heavy forklift traffic and point loads from racking systems. The design demanded precise reinforcement placement to manage stress concentrations effectively. Our tailored Construction Reinforced Steel Bar Welded Wire Mesh solution, featuring larger bar diameters and specialized mesh patterns, was selected. The client praised the ease of installation and the minimal deflection observed in the finished floor. Feedback indicated that the high-quality welds and consistent bar spacing provided superior performance against plastic shrinkage and temperature-induced cracking, which are common issues in large industrial slabs.

Case Study 3: Precast Concrete Bridge Segments

For a critical bridge construction project, prefabricated concrete segments were utilized to expedite erection. The precast manufacturer required exceptionally accurate and consistent reinforcement cages. By integrating our customized welded wire mesh, they were able to achieve precise reinforcement positioning within the molds, which is vital for the structural integrity of precast elements. The automated nature of the mesh fabrication also streamlined their production line, reducing manual errors and improving overall efficiency. This partnership ensured that thousands of identical, high-quality bridge segments were produced on schedule and to exact specifications.

Trust and Support: FAQ, Lead Time, Warranty

Establishing trust and providing unwavering support are cornerstones of our commitment to clients. We ensure transparent communication regarding product details, logistics, and post-purchase services for our Construction Reinforced Steel Bar Welded Wire Mesh.

Frequently Asked Questions (FAQ):

- Q1: What are the primary advantages of welded wire mesh over traditional rebar?

- A1: Welded wire mesh offers faster installation, superior dimensional accuracy, reduced labor costs, minimal material waste, and enhanced structural integrity due to consistent weld strength and precise bar spacing.

- Q2: Can your welded wire mesh be customized for specific project requirements?

- A2: Absolutely. We specialize in customized solutions, including varying bar diameters, mesh spacings, panel sizes, and specialized coatings to meet unique engineering designs and project-specific needs.

- Q3: What quality standards does your product adhere to?

- A3: Our products comply with stringent international standards such as ISO 9001:2015 for quality management, and product-specific standards like ASTM A1064/A1064M, BS 4483, and AS/NZS 4671, ensuring the highest levels of quality and performance.

Lead Time and Fulfillment:

We understand the critical nature of project schedules. Our advanced manufacturing capabilities and efficient logistics network enable us to offer competitive lead times. For standard orders, typical lead times range from 5 to 10 business days. Custom orders or large volumes may require slightly longer, which will be clearly communicated during the quotation process. We maintain robust inventory levels of common configurations and offer expedited shipping options for urgent requirements.

Warranty Commitments:

We stand by the quality and performance of our Construction Reinforced Steel Bar Welded Wire Mesh. Our products come with a standard warranty against manufacturing defects and material non-conformance for a period typically aligning with industry best practices, generally covering the structural integrity of the mesh for up to [e.g., 1 year] from the date of purchase, provided it is stored, handled, and installed in accordance with industry standards and our recommendations. Detailed warranty terms are available upon request.

Customer Support and Technical Assistance:

Our dedicated customer support team and experienced technical engineers are available to assist with product selection, technical specifications, design optimization, and any post-delivery inquiries. We provide comprehensive technical documentation, installation guidelines, and on-site support where necessary, ensuring a seamless experience for our clients from initial inquiry through project completion. Our commitment is to be a reliable partner in your construction endeavors.

References

- ASTM A1064/A1064M-18, Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete. ASTM International.

- BS 4483:2005, Steel fabric for the reinforcement of concrete – Specification. British Standards Institution.

- ACI 318-19, Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute.

- ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025