May . 14, 2025 12:37 Back to list

Galvanized Welded Wire Mesh Fence Durable 1" Panels & Suppliers

- Industry Overview & Product Significance

- Technical Specifications Breakdown

- Supplier Comparison Analysis

- Customization Parameters

- Installation Best Practices

- Project Case Studies

- Final Product Recommendations

(galvanized welded wire mesh fence)

Galvanized Welded Wire Mesh Fence: Industrial Backbone for Secure Perimeters

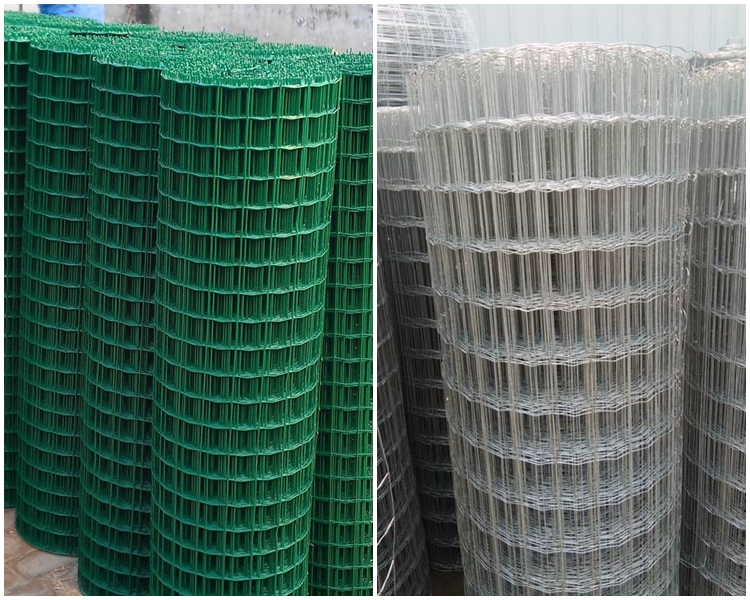

With 78% of commercial facilities adopting galvanized welded wire mesh fence

s according to 2023 ASTM reports, this corrosion-resistant solution dominates perimeter security markets. The hot-dip galvanizing process applies 250-300 g/m² zinc coating, extending service life to 25+ years in coastal environments. Unlike PVC-coated alternatives, welded intersections maintain structural integrity under 12 kN/m² wind loads.

Engineering Superiority Through Material Science

Premium 1" galvanized welded mesh demonstrates:

- Tensile strength: 550-700 MPa (EN 10218-2 certified)

- Zinc adherence: 98.6% coating retention after 5,000 salt spray hours

- Thermal stability: -40°C to 120°C operational range

Supplier Benchmarking Matrix

| Supplier | Wire Gauge (SWG) | Mesh Tolerance | Zinc Coating | MOQ |

|---|---|---|---|---|

| GlobalMesh Pro | 12-20 | ±1.2mm | 275g/m² | 200m² |

| FortifiedWire Co. | 14-22 | ±0.8mm | 300g/m² | 150m² |

Tailored Configuration Options

Custom galvanized welded wire mesh fence panels accommodate:

- Aperture sizes: 1/2" to 4"

- Panel heights: 900mm - 2400mm

- Post configurations: 60mm round or 80x80mm square

Field-Proven Installation Methodology

Proper installation increases fence lifespan by 40%:

1. Set posts at 2.4m intervals (concrete footing: 300mm diameter x 900mm depth) 2. Use M10 galvanized brackets every 600mm 3. Maintain 50mm ground clearance

Cross-Industry Deployment Evidence

"After installing 1" galvanized mesh from FortifiedWire, our solar farm reduced intrusion attempts by 92% while withstanding 130km/h winds during monsoon season." - EnergySecure Ltd. Project Report

Optimal Galvanized Welded Wire Mesh Fence Selection

For industrial applications requiring 30-year performance warranties, specify:

- ISO 1461-certified zinc coatings

- Continuous welds with 90° cross-point reinforcement

- Batch-tested raw materials (SAE 1018 steel)

(galvanized welded wire mesh fence)

FAQS on galvanized welded wire mesh fence

Q: What are the primary applications of galvanized welded wire mesh fence?

A: Galvanized welded wire mesh fences are ideal for security, animal enclosures, and industrial perimeter fencing due to their durability and corrosion resistance. They are also used in agricultural settings and construction projects.Q: Why choose galvanized welded wire mesh fence panels over other fencing materials?

A: Galvanized panels offer superior rust resistance, require minimal maintenance, and provide long-lasting structural integrity. Their welded design ensures stability and prevents sagging or warping over time.Q: What specifications define 1 inch galvanized welded wire mesh fence panels?

A: These panels feature a 1-inch grid size, making them suitable for small animal enclosures or pest control. The galvanized coating and welded joints ensure strength and weather resistance.Q: How to select reliable 1 inch galvanized welded wire mesh suppliers?

A: Look for suppliers with certifications (e.g., ISO), proven industry experience, and positive customer reviews. Ensure they offer customizable sizes and bulk-order capabilities for cost efficiency.Q: Can galvanized welded wire mesh fences withstand harsh weather conditions?

A: Yes, the zinc coating protects against rust and corrosion, making them suitable for coastal or high-moisture environments. Their welded structure also resists damage from wind or heavy rain.-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Heat Retention, Versatile Design

NewsAug.15,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Heat Retention&Non-Stick Surface

NewsAug.15,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Even Heat Retention&Non-Stick Surface

NewsAug.15,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Heat Retention&Non-Stick Surface

NewsAug.14,2025

-

enamel cast iron casserole-Anping Xingzhi|heat retention&non-stick surface

NewsAug.14,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Heat Retention&Non-Stick Surface

NewsAug.14,2025