Aug . 06, 2025 00:20 Back to list

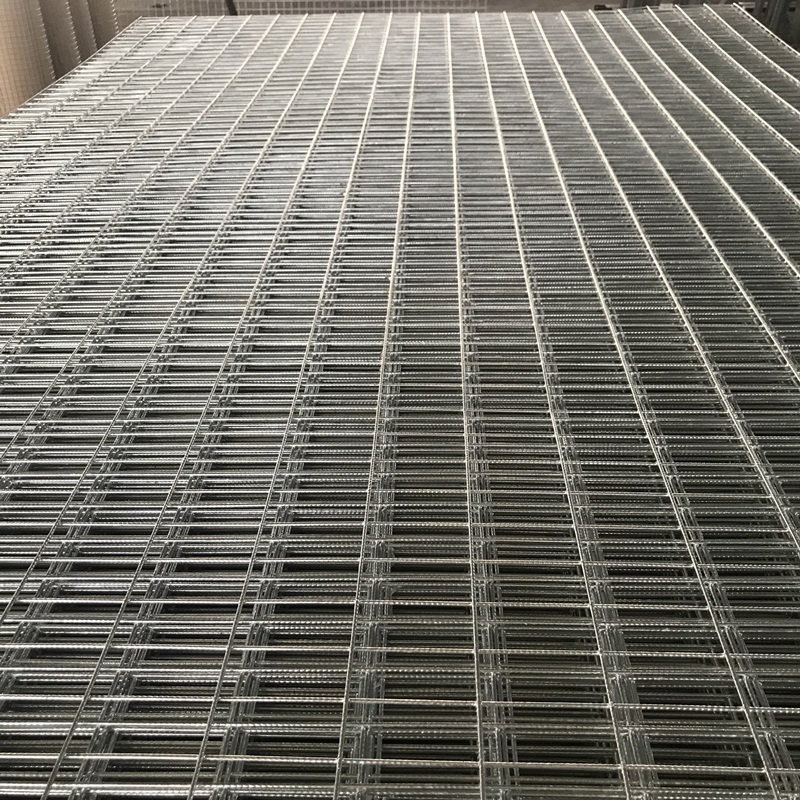

Durable Reinforced Steel Bar Welded Wire Mesh for Construction

Elevating Structural Integrity and Construction Efficiency with Precision-Engineered Reinforcement Solutions. Discover the technology, applications, and advantages of the industry's preferred choice.

Explore Our Product RangeThe Evolution of Concrete Reinforcement: Industry Trends and Projections

The global construction industry is undergoing a seismic shift towards efficiency, safety, and sustainability. In this new paradigm, traditional methods of on-site rebar tying are being rapidly replaced by superior, prefabricated solutions. At the forefront of this revolution is the Construction Reinforced Steel Bar Welded Wire Mesh, also known as welded wire fabric (WWF). Market analysis indicates a projected compound annual growth rate (CAGR) of 5.8% for the steel rebar market, with a significant portion of this growth driven by the adoption of value-added products like welded mesh. This trend is fueled by the undeniable benefits: reduced labor costs, accelerated project timelines, and enhanced structural precision.

Modern mega-projects, from high-rise buildings to extensive infrastructure networks, demand a level of quality control that is difficult to achieve with manual rebar placement. Construction Reinforced Steel Bar Welded Wire Mesh offers a factory-produced, high-quality alternative that guarantees exact spacing and superior weld strength, directly contributing to the safety and longevity of the finished structure. As building codes become more stringent, particularly regarding seismic and load-bearing requirements, the adoption of engineered mesh that complies with standards like ASTM A1064/A1064M is no longer an option but a necessity.

Labor Efficiency: Welded Mesh vs. Traditional Rebar Tying

Data illustrates up to 50% reduction in on-site labor hours.

Market Adoption Growth (Prefabricated Reinforcement)

Projected steady growth as efficiency demands increase.

Unpacking the Technical Specifications: A Deep Dive into Quality

Understanding the technical parameters of Construction Reinforced Steel Bar Welded Wire Mesh is crucial for engineers, architects, and project managers. These specifications are not just numbers; they are a guarantee of performance, safety, and compliance. The quality of the final product is a direct result of the raw materials used, the manufacturing precision, and adherence to rigorous international standards.

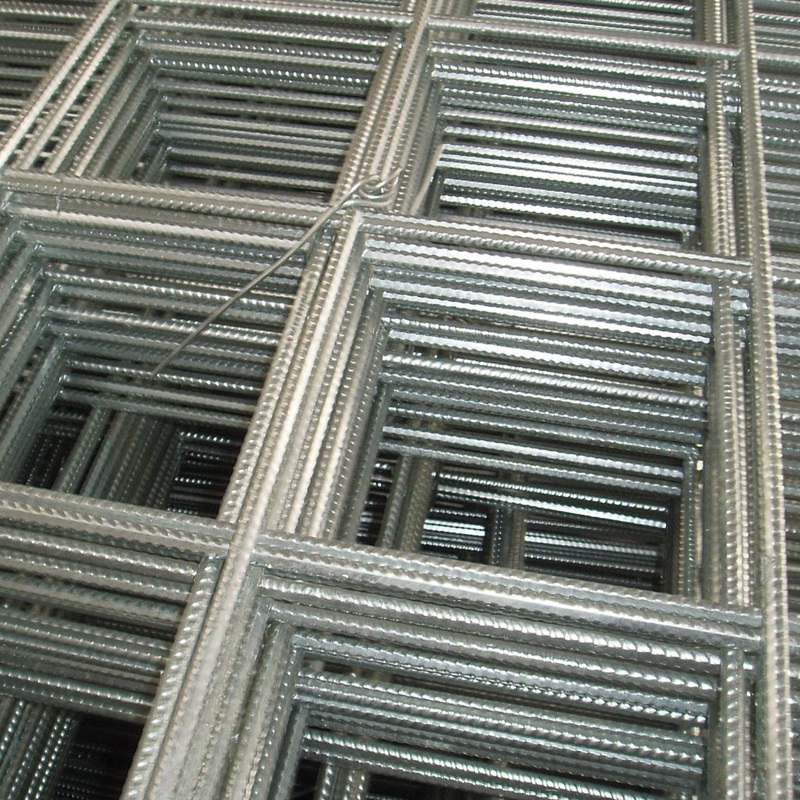

Our mesh is fabricated from high-tensile, low-carbon steel, typically conforming to grades like HRB400 or HRB500, which offer an optimal balance of strength and ductility. The wires can be either smooth or deformed (ribbed), with deformed wires providing superior mechanical bonding with concrete, thus minimizing crack widths and improving overall structural performance. The table below outlines typical specifications available, but we specialize in providing custom solutions tailored to specific project requirements.

| Parameter | Specification Range | Standard Compliance | Significance |

|---|---|---|---|

| Wire Diameter | 4.0mm - 12.0mm | ASTM A1064/A1064M, BS4483 | Determines the tensile strength and load-bearing capacity of the mesh. |

| Mesh Opening (Pitch) | 50x50mm to 300x300mm | Project Specific / As per Code | Ensures uniform stress distribution and proper concrete aggregate flow. |

| Sheet/Roll Width | Up to 2.5 meters | N/A | Optimized for transport and to minimize on-site lapping, reducing waste. |

| Sheet/Roll Length | Up to 12 meters (Sheets), 50m+ (Rolls) | N/A | Allows for rapid coverage of large areas like floor slabs and pavements. |

| Weld Shear Strength | ≥ 35% of Tensile Strength of Wire | ANSI/AWS D1.4 | Critical for maintaining the integrity of the grid during handling and concrete pouring. |

| Material Grade | HRB400, HRB500, Grade 60, etc. | ASTM A615, ISO 6935-2 | Defines the steel's yield strength, crucial for structural calculations. |

The Heart of Performance: The Manufacturing Process Explained

The superior quality of our Construction Reinforced Steel Bar Welded Wire Mesh is not accidental; it is the result of a meticulously controlled, automated manufacturing process. This process ensures a level of precision and consistency that is unattainable with manual methods. Each step is monitored to comply with ISO 9001 quality management standards.

1. Raw Material Selection

High-grade steel rods (e.g., SAE 1008) are selected based on strict chemical and mechanical property requirements.

2. Wire Drawing & Ribbing

Rods are drawn through dies to the precise diameter. Deformations (ribs) are cold-rolled onto the surface for enhanced concrete bond.

3. Straightening & Cutting

The drawn wire is straightened and cut to exact lengths for longitudinal and transverse wires by CNC-controlled machines.

4. Automated Resistance Welding

Wires are arranged in a grid and fused at each intersection using a high-current, low-voltage electrical process. This creates a monolithic, structurally sound joint.

5. Quality Inspection

Each batch undergoes rigorous testing: dimensional accuracy, wire tensile strength, and critical weld shear strength tests to meet ANSI/AWS standards.

Key Technical Advantages Over Traditional Methods

Choosing Construction Reinforced Steel Bar Welded Wire Mesh is an investment in efficiency, safety, and quality. Here’s a breakdown of the core benefits:

- Unmatched Speed & Efficiency: Prefabricated sheets or rolls can be laid out in a fraction of the time it takes to place and tie individual bars. This directly translates to significant reductions in labor costs and faster project completion, a critical factor in today's competitive market.

- Guaranteed Quality & Precision: Factory automation eliminates the human error associated with manual tying. The precise spacing of wires ensures uniform reinforcement distribution, which is vital for predictable structural behavior and compliance with engineering designs.

- Superior Structural Integrity: The welded intersections create a rigid mat that resists displacement during concrete pouring. The strong, uniform bonds provided by deformed wires and robust welds enhance load distribution and crack control.

- Reduced Material Waste: Mesh is designed with optimal lapping, and custom-sized sheets can be produced to minimize offcuts. This contrasts sharply with the significant waste generated from cutting and overlapping loose rebar on-site, contributing to a more sustainable (节能) construction practice.

- Enhanced Site Safety: Reducing the amount of loose rebar on the ground and minimizing the time workers spend bending and tying in awkward positions leads to a safer construction environment with fewer trip hazards and repetitive strain injuries.

- Corrosion Resistance Options: For projects in harsh environments (e.g., marine structures, bridges, chemical plants), the mesh can be supplied with protective coatings such as hot-dip galvanization or epoxy coating, dramatically increasing its service life by preventing corrosion (防腐蚀).

Application Spotlight: Where Performance Matters Most

The versatility of Construction Reinforced Steel Bar Welded Wire Mesh makes it an indispensable component across a wide spectrum of construction and civil engineering projects.

Core Application Scenarios:

- Slabs-on-Grade & Foundations: Its primary use is in reinforcing concrete floor slabs in residential, commercial, and industrial buildings. It provides excellent temperature and shrinkage crack control, ensuring a durable and stable foundation.

- Pavements & Roadways: In concrete highways, airport runways, and parking lots, welded mesh provides the tensile strength needed to withstand heavy traffic loads and prevent cracking due to thermal expansion and contraction.

- Structural Walls & Precast Elements: It is widely used in tilt-up wall panels, retaining walls, and other precast concrete components. The rigidity of the mesh simplifies production and ensures accurate rebar placement within the forms.

- Bridge Decks, Tunnels, and Culverts: For major infrastructure projects, the reliability and speed of installation make it the ideal choice. Coated versions are often specified for these applications to ensure long-term durability against environmental exposure.

- Mining and Slope Stabilization: In shotcrete applications, welded mesh provides a robust framework for stabilizing rock faces and tunnel linings.

Case Study: High-Rise Commercial Tower Foundation

A recent project for a 40-story commercial building required the rapid construction of a large mat foundation. The engineering firm specified our custom-dimensioned 10mm deformed Construction Reinforced Steel Bar Welded Wire Mesh. Client feedback highlighted a 45% reduction in reinforcement installation time compared to their initial projections based on traditional rebar tying. The project manager noted, "The precision and rigidity of the mesh from XZMetal not only saved us invaluable time but also gave our structural engineers complete confidence in the quality of the reinforcement, passing all inspections without issue."

Customization: Your Project, Your Specifications

We understand that no two construction projects are the same. That's why we offer comprehensive customization for our Construction Reinforced Steel Bar Welded Wire Mesh. Our technical team works directly with your engineers and architects to design and manufacture mesh that perfectly aligns with your structural drawings and project requirements.

Customization options include:

- Variable Wire Diameters: Different diameters can be used for longitudinal and transverse wires within the same sheet.

- Non-Standard Spacing: Custom grid patterns to accommodate unique load requirements or embedded items.

- Cut-to-Size Sheets: Precisely dimensioned sheets to minimize on-site cutting and waste.

- Special Overhangs: Custom wire overhangs to facilitate lapping and connections.

- Protective Coatings: Hot-dip galvanized, electro-galvanized, or epoxy-coated finishes for enhanced corrosion protection.

Our Commitment to Trust and Authority (E-E-A-T)

At XZMetal, we build trust through transparency, expertise, and an unwavering commitment to quality. Our products and processes are designed to meet and exceed the highest industry expectations.

- (E)xpertise: Our team consists of metallurgists and engineers with decades of combined experience in steel reinforcement technology. We provide expert consultation to ensure you select the optimal product for your application.

- (E)xperience: With over 15 years serving the global construction industry, we have supplied mesh for thousands of projects, from residential homes to national infrastructure. Our case studies reflect this deep, practical experience.

- (A)uthoritativeness: We are an ISO 9001:2015 certified company. Our products are manufactured in compliance with international standards like ASTM, BS, and DIN, making us a trusted partner for projects worldwide.

- (T)rustworthiness: We offer comprehensive Material Test Certificates (MTCs) with every shipment, detailing chemical composition and mechanical properties. Our transparent pricing, clear communication on delivery timelines, and robust after-sales support ensure a reliable partnership.

Frequently Asked Questions (FAQ)

Plain wire mesh has smooth wires, while deformed wire mesh has ribs or indentations rolled onto the wire surface. This deformation creates a much stronger mechanical bond with the concrete, significantly improving anchorage and crack control. Deformed Construction Reinforced Steel Bar Welded Wire Mesh is generally specified for structural applications where load-bearing capacity is critical, as recommended by ACI 318.

The most critical standard in North America is ASTM A1064/A1064M, which covers "Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete." In the UK and related regions, BS 4483 is the key standard. It's essential to ensure your supplier can provide certification of compliance with the relevant standard for your project's location and building codes.

Weld shear strength is tested by pulling a welded intersection apart until it fails. According to standards like ANSI/AWS D1.4, the weld must withstand a force equal to at least 35% of the specified tensile strength of the wire. This is crucial because it ensures the mesh remains a single, rigid unit during transportation, handling, and the stresses of concrete pouring. A weak weld can lead to displacement of reinforcement and compromise the structure's integrity.

Absolutely. Reputable manufacturers like XZMetal specialize in providing customized solutions. This includes non-standard sheet sizes, variable wire spacings, and different wire diameters for longitudinal and transverse directions. Providing your engineering drawings allows us to fabricate Construction Reinforced Steel Bar Welded Wire Mesh that perfectly fits your design, minimizing waste and on-site labor.

The primary cost saving is in labor. Laying prefabricated mesh can be 50-60% faster than placing and tying loose bars. Secondary savings come from reduced material waste, faster project turnaround (which lowers overall site overheads), and improved quality control that prevents costly rework. The initial material cost per ton might be slightly higher, but the total installed cost is significantly lower.

This depends entirely on the service environment of the concrete structure. For standard interior slabs or foundations in non-corrosive soil, standard (black) steel mesh is sufficient. However, for structures exposed to moisture, de-icing salts, or chemicals (e.g., bridge decks, parking garages, marine structures, wastewater treatment plants), a protective coating is essential. Hot-dip galvanizing or epoxy coating provides a barrier that significantly extends the structure's lifespan by preventing rust and steel degradation.

Lead times vary based on order size, complexity, and current production schedules. A typical order for standard mesh might have a lead time of 2-3 weeks, while highly customized orders may take 4-5 weeks. The mesh is typically delivered in securely bundled flat sheets or compact rolls, optimized for container111 shipping and easy handling on-site with a crane or forklift. We provide detailed logistics support to ensure timely delivery to your project site anywhere in the world.

Authoritative References & Further Reading

The information and best practices presented in this article are supported by leading industry bodies and research. For more in-depth technical information, we recommend consulting the following resources:

-

Concrete Reinforcing Steel Institute (CRSI): A primary authority on steel-reinforced concrete construction. Their publications provide invaluable design aids and technical data.

Reference: CRSI, "Manual of Standard Practice," (2018). Available at: www.crsi.org -

ASTM International: The body that develops and publishes technical standards for materials, including steel reinforcement.

Reference: ASTM A1064 / A1064M-18a, "Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete," ASTM International, West Conshohocken, PA, 2018. Available at: www.astm.org -

Journal of Materials in Civil Engineering: A peer-reviewed journal featuring research on construction materials.

Reference: Hamad, B. S., & Rteil, A. A. (2006). "Bond of Epoxy-Coated Reinforcement: Splice Strength and Development Length." Journal of Materials in Civil Engineering, 18(2), 237-246. Available at: ascelibrary.org

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025