Dic . 23, 2024 00:30 Back to list

High-Quality Custom Aluminum Expanded Metal Mesh for Various Applications

Custom Aluminum Expanded Metal Mesh A Versatile Solution for Various Applications

In the realm of industrial materials, aluminum expanded metal mesh stands out for its unique properties and applications. This innovative product is made by cutting and stretching aluminum sheets to create a network of interconnected diamond-shaped openings. The result is a material that is lightweight, durable, and versatile, making it a popular choice across a multitude of industries. Let's explore the benefits, manufacturing process, and applications of custom aluminum expanded metal mesh.

The Advantages of Aluminum Expanded Metal Mesh

One of the most significant advantages of aluminum expanded metal mesh is its lightweight nature. Aluminum is inherently lighter than many other metals, which means that structures and components can be manufactured without excessive weight, facilitating easier installation and transportation. This aspect is particularly valuable in applications where weight reduction is crucial, such as in the aerospace and automotive industries.

Another key benefit of aluminum expanded metal mesh is its excellent strength-to-weight ratio. Despite being lightweight, aluminum mesh provides remarkable tensile strength and rigidity, making it ideal for structural applications. This strength is enhanced through the mesh structure itself, where the interlinked patterns help distribute loads evenly, reducing the risk of deformation or failure.

Corrosion resistance is another prominent feature of aluminum. When exposed to the elements, aluminum naturally forms a protective oxide layer that helps prevent rust and deterioration. This makes aluminum expanded metal mesh particularly suitable for outdoor applications or in environments where exposure to moisture is a concern.

Customization Options

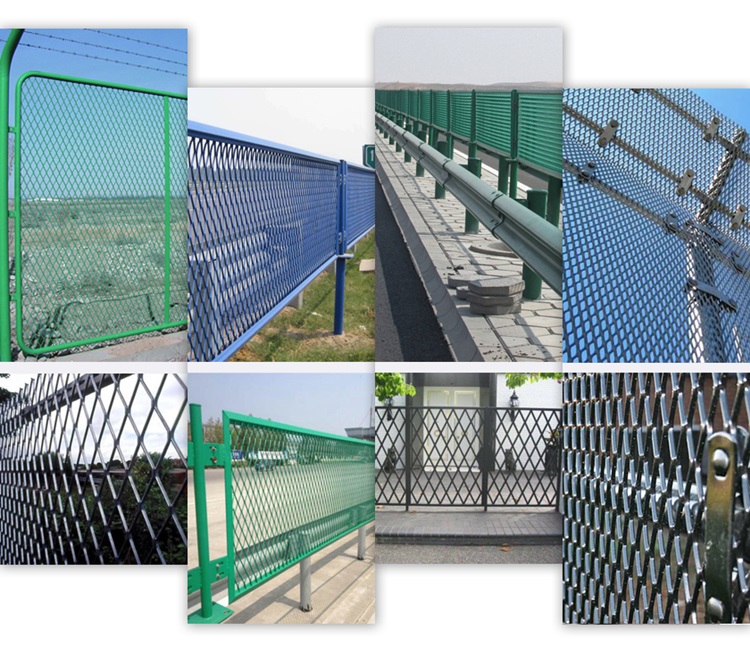

The versatility of aluminum expanded metal mesh also lies in its customization options. Manufacturers can create mesh products in a range of sizes, shapes, and patterns to meet specific requirements. Custom openings can be designed to allow for varying levels of airflow, visibility, and security, making it suitable for diverse applications including fencing, grilles, and filters.

Thickness and gauge options also afford users the ability to choose the strength and durability of the mesh to suit their needs. Additionally, finishes such as anodizing or powder coating can enhance the aesthetic appeal and functionality of the product, providing options for decorative elements in architectural designs.

custom aluminum expanded metal mesh

Manufacturing Process

The manufacturing of aluminum expanded metal mesh involves a series of precise steps to ensure quality and consistency. Initially, flat sheets of aluminum are fed into cutting machines that make a series of strategic cuts. The sheets are then stretched to create the mesh pattern. This process transforms the flat metal into a three-dimensional structure, strengthening the material while maintaining its lightweight properties.

Quality control is paramount in the manufacturing process, ensuring that every batch of expanded metal mesh meets industry standards and customer specifications. This commitment to quality guarantees that the final product is not only reliable but also capable of performing well under a variety of conditions.

Applications of Aluminum Expanded Metal Mesh

The applications of custom aluminum expanded metal mesh are nearly limitless. In architecture, it is often employed for decorative facades, privacy screens, and sunshades, allowing for both aesthetic appeal and functional performance. The mesh can be used to facilitate airflow and natural light while maintaining security and privacy.

In industrial settings, aluminum expanded metal mesh is commonly used for safety guards, walkways, and ventilation grilles. Its ability to withstand heavy loads whilst providing an open structure makes it ideal for platforms and stair treads. Additionally, it serves as an excellent material for custom storage systems and shelving units where visibility and accessibility are essential.

Moreover, in the world of art and design, aluminum expanded metal mesh is increasingly used by artists and designers to create striking installations and modern furnishings. Its unique texture and appearance add dimension to projects, allowing for creative expression and innovation.

Conclusion

In conclusion, custom aluminum expanded metal mesh represents a versatile solution that combines strength, lightness, and aesthetic appeal. With its wide range of applications across various industries—from architectural elements to industrial uses—this material continues to gain popularity. The ability to customize the mesh to meet specific requirements further enhances its value, making it a preferred choice for many professionals seeking reliable and innovative solutions. As industries evolve and the demand for lightweight, durable materials grows, aluminum expanded metal mesh is poised to play an even more significant role in the future of design and construction.

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025