Aug . 12, 2025 11:20 Back to list

Stainless Steel Screws-Corrosion Resistance & Durability|Anping County Xingzhi Metal Wiremesh Products Co., Ltd

Stainless steel screws have become a cornerstone in modern engineering and construction due to their exceptional durability, corrosion resistance, and versatility. These fasteners are engineered to withstand harsh environments while maintaining structural integrity, making them indispensable across industries such as construction, automotive, marine, and electronics. This article explores the key features, technical specifications, and applications of stainless steel screws, along with insights into the company behind this innovative product: Anping County Xingzhi Metal Wiremesh Products Co., Ltd..

Product Overview

Stainless steel screws are premium fastening solutions designed for strength, durability, and long-lasting performance in diverse applications. Crafted from high-quality stainless steel, these screws exhibit remarkable resistance to rust, corrosion, and wear, making them ideal for both indoor and outdoor environments. Their ability to endure extreme conditions while providing a secure and robust hold has cemented their reputation as a reliable choice for a wide range of fastening needs.

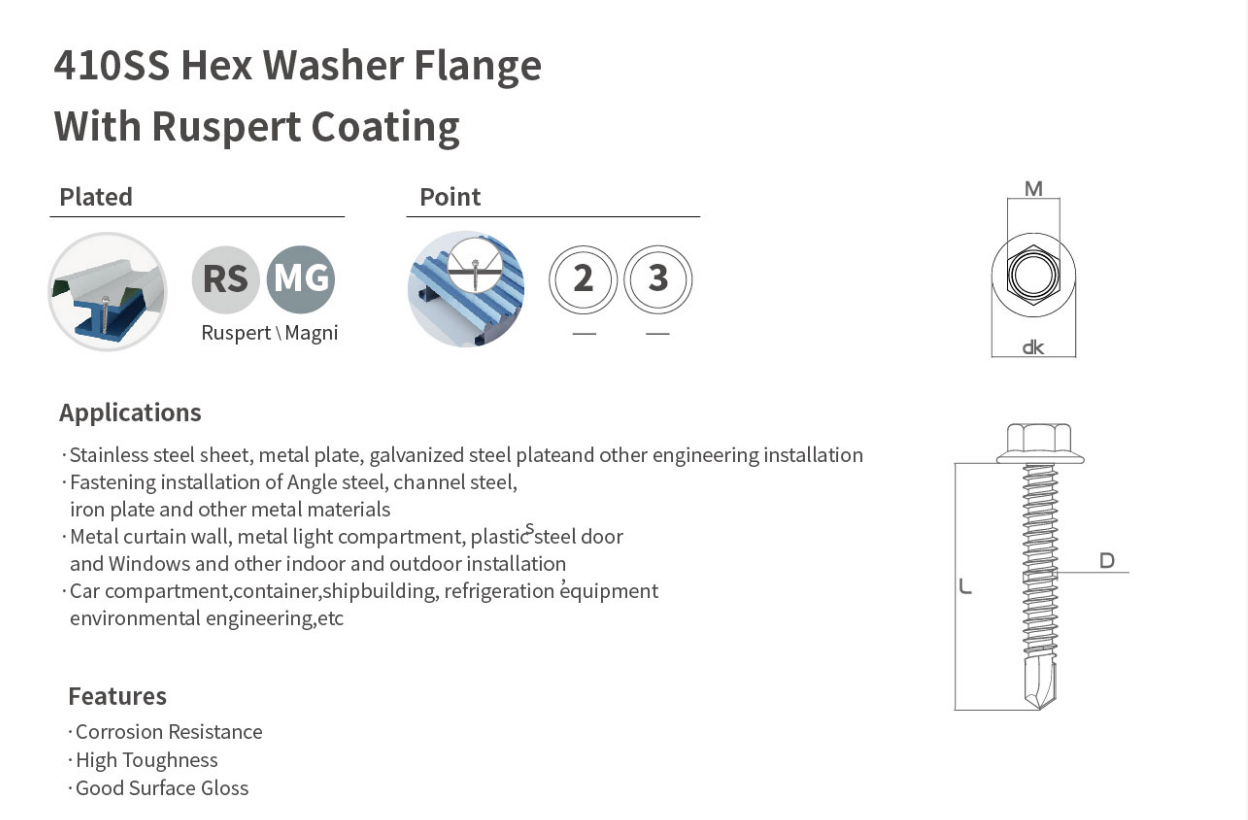

Key Features of Stainless Steel Screws

1. Exceptional Corrosion Resistance

One of the standout advantages of stainless steel screws is their superior corrosion resistance. The inherent properties of stainless steel, such as a chromium-rich surface layer, prevent rust and degradation even in high-humidity or saltwater environments. This makes them particularly suitable for marine applications, coastal construction, and industrial settings where exposure to moisture is inevitable.

2. Superior Strength and Load-Bearing Capacity

Stainless steel screws are engineered to deliver exceptional tensile strength and load-bearing capabilities. They are designed to endure heavy-duty applications, ensuring a secure hold for materials such as wood, metal, concrete, and plastics. This strength is critical in structural projects where failure could lead to catastrophic consequences.

3. Versatility in Applications

These screws are incredibly versatile, catering to a wide array of uses. From construction and automotive to electronics and marine applications, their resistance to rust and corrosion makes them ideal for both exterior and interior projects. For instance, 10 x 1 stainless steel screws are commonly used in roofing and siding, while 12 x 1 stainless steel screws are preferred for heavy-duty structural components.

4. Aesthetic Appeal

Stainless steel screws offer a sleek, clean appearance that complements modern, high-end designs. Their polished, shiny finish adds aesthetic value to furniture, fixtures, and architectural components. This makes them a popular choice for projects where both functionality and visual appeal are paramount.

5. Ease of Installation

With a range of head types, thread patterns, and sizes, stainless steel screws are easy to install using standard tools. Their precision threading ensures a tight grip, and their durability minimizes the risk of stripping or damaging the screw during installation. For example, 8 x 1 stainless steel screws are often used in delicate electronics due to their fine threading and compact size.

Applications of Stainless Steel Screws

1. Construction Industry

In construction, stainless steel screws are used to secure materials such as wood, drywall, and metal. Their corrosion resistance ensures they can withstand exposure to outdoor elements in roofing, siding, and framing applications. For example, 12 x 1 stainless steel screws are frequently employed in structural framing to prevent rust and maintain long-term stability.

2. Automotive and Marine Industries

In the automotive and marine sectors, stainless steel screws are used to secure parts and components exposed to moisture, saltwater, and other harsh conditions. Their corrosion resistance ensures reliability and longevity in vehicles and boats. 10 x 1 stainless steel screws are commonly found in marine equipment, such as boat hulls and deck fittings, where exposure to saltwater is a constant challenge.

3. Electronics

Stainless steel screws are used in electronics to secure components like circuit boards, devices, and housings. The non-corrosive properties of these screws ensure long-term stability and reliability for electronic systems. Their precision and durability make them ideal for applications requiring minimal maintenance, such as industrial control panels and consumer electronics.

4. DIY and Home Improvement

For DIY projects, stainless steel screws are a popular choice for furniture assembly, decking, and cabinetry. Their durable finish ensures a clean, polished look while providing a strong, long-lasting hold. 8 x 1 stainless steel screws are often used in furniture making due to their balance of strength and aesthetics.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | High-quality stainless steel (e.g., 304, 316 grades) |

| Head Types | Hex, flat, pan, and socket head options |

| Thread Patterns | Coarse (UNC) and fine (UNF) threads |

| Size Range | From 1 x 1 mm to 12 x 1 mm (varies by application) |

| Finish | Polished, shiny, and corrosion-resistant surface |

| Corrosion Resistance | High resistance to rust, saltwater, and humidity |

About the Manufacturer: Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

Anping County Xingzhi Metal Wiremesh Products Co., Ltd. is a leading manufacturer of high-quality metal fasteners, including stainless steel screws. With a focus on innovation and precision engineering, the company has established itself as a trusted supplier in the global market. Their products are designed to meet stringent industry standards, ensuring reliability and performance in demanding environments.

The company’s commitment to quality is evident in its product specifications, which emphasize corrosion resistance, high toughness, and a good surface gloss. These attributes align with the needs of industries that require durable and aesthetically pleasing fasteners.

Why Choose Stainless Steel Screws?

Stainless steel screws offer a unique combination of strength, durability, and versatility that makes them ideal for a wide range of applications. Their resistance to corrosion ensures longevity, while their aesthetic appeal enhances the visual quality of finished projects. Additionally, their ease of installation and compatibility with standard tools make them a practical choice for professionals and DIY enthusiasts alike.

For industries where reliability is critical, such as aerospace, automotive, and marine engineering, stainless steel screws provide a dependable solution. Their ability to perform under extreme conditions sets them apart from other fastening options, making them a preferred choice for high-stakes applications.

Conclusion

Stainless steel screws are a testament to the power of advanced materials engineering. Their exceptional properties—corrosion resistance, strength, and versatility—make them indispensable in modern construction, manufacturing, and design. Whether you are working on a large-scale industrial project or a small DIY task, these fasteners offer a reliable and durable solution.

For more information about stainless steel screws and the products offered by Anping County Xingzhi Metal Wiremesh Products Co., Ltd., visit their official website. Explore their range of fasteners and discover how they can elevate your next project.

References

As per the National Institute of Standards and Technology (NIST), material standards and testing procedures play a critical role in ensuring the quality and performance of industrial products. While specific references to stainless steel screws were not found in the provided NIST content, the agency’s work in material science and engineering standards underscores the importance of rigorous testing and certification in the manufacturing of high-performance fasteners. For further details on NIST’s contributions to material standards, visit their official website.

Source: https://www.nist.gov

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025