Aug . 02, 2025 00:20 Back to list

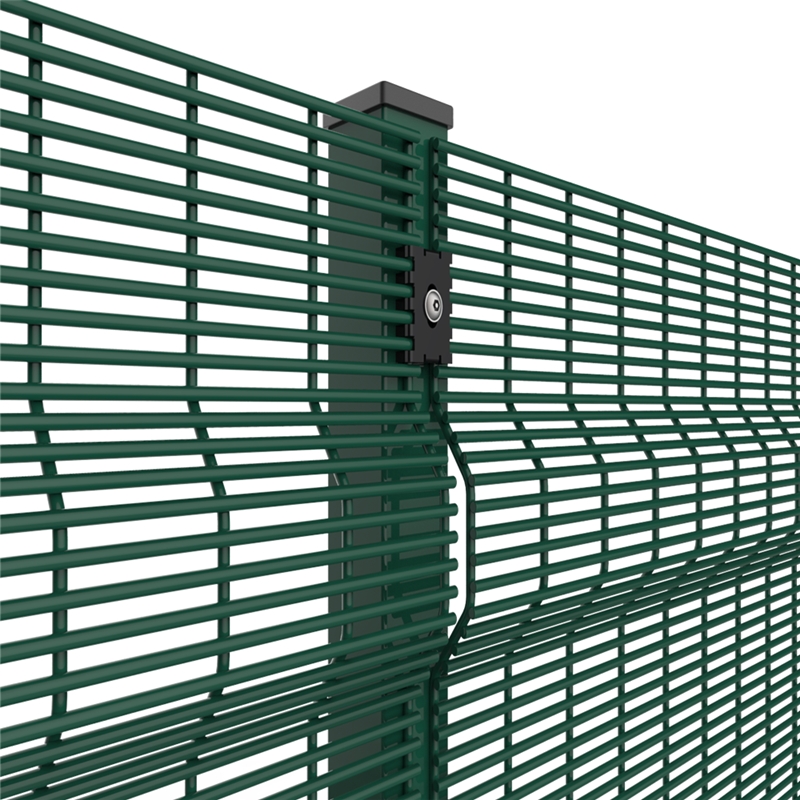

358 Anti Climb Welded Wire Mesh Fence - Secure Perimeter Defense

358 Anti Climb Welded Wire Mesh Fence has become the gold standard in modern high-security perimeter solutions, especially for critical infrastructure, correctional facilities, industrial properties, and transport hubs. This comprehensive guide will showcase industry data, technical insights, and real-world applications, putting a spotlight on manufacturing intricacies and authoritative certifications. Here, you'll discover why 358 Anti Climb Welded Wire Mesh Fence is the top choice for robust, tamper-proof boundary protection.

1. Industry Overview & Global Trends

The global market for 358 Anti Climb Welded Wire Mesh Fence has seen rapid growth due to increasing concerns in critical infrastructure protection, terrorism threats, and stricter standards. According to Market Research Future, the welded wire mesh market is expected to surpass USD 7 billion by 2027, with anti-climb variants representing over 30% of all demand.

- Key Market Drivers: Security reinforcement, urban transit expansion, new correctional facility projects, and stringent government regulations.

- Major Adopters: Petrochemical plants, power substations, prisons, airports, seaports, and public utilities.

- Compliance: Growing number of procurement projects demand ISO 9001 & ANSI/ASTM F2781-certified mesh fences.

2. What is a 358 Anti Climb Welded Wire Mesh Fence?

The term 358 specifies mesh size: 3" x 0.5" (76.2mm x 12.7mm) with typically 8-gauge (4mm) wire diameter. This combination ensures exceptional rigidity, minimal hand/foot purchase, and high anti-cut resistance, rendering the fence virtually impossible to climb, cut with hand tools, or breach clandestinely.

| Parameter | Specification | Industry Standard |

|---|---|---|

| Mesh Opening | 76.2mm x 12.7mm (3" × 0.5") | EN 10223-7 |

| Wire Diameter | 4.0mm (8 gauge) | ASTM A975 |

| Panel Height | 2134mm – 3580mm | Customizable |

| Panel Width | 2515mm (Standard) | Customizable |

| Finish | Hot-dip galvanized / Polyester powder coated | ISO 1461/ASTM F1043 |

| Coating Thickness | 60-100μm | ISO 1461/BS EN 13438 |

| Ultimate Tensile Strength | >500 MPa | ISO 6892-1 |

3. Technical Parameters: Comprehensive Data Overview

4. Manufacturing Process: From Raw Material to Finished Fence

(Q195/Q235 steel rod; chemical composition tested, per ISO 6892-1) Wire Drawing Automatic Welding

(CNC mesh welding, vertical/horizontal wires fusion point tracking) Surface Treatment

1. Hot-dip Galvanizing

2. Degreasing

3. Powder Coating Inspection & Quality Testing

(Adhesion, thickness, corrosion & tensile test per ISO 9227/1461 & ASTM B117) Packing & Shipment

Key Process Highlights:

- CNC Welding: Ensures flatness and structural integrity, with tight aperture tolerances to ISO 9001 quality standards.

- Galvanization & Coating: Dual-process—hot galvanization for rust resistance, followed by polyester powder coating for UV/weather hardiness.

- Quality Assurance: 100% panels pass salt spray test (over 500h, per ISO 9227), weld shear test, and documentation traceability.

5. Comparative Product Analysis

| Feature | 358 Anti Climb Welded Wire Mesh Fence | Chain Link Fence | Palisade Fence |

|---|---|---|---|

| Anti-Climb Effectiveness | ★★★★★ (Finger-proof mesh, no footholds) | ★★ (Scalable with tools) | ★★★☆ (Difficult, but possible) |

| Cut Resistance | ★★★★★ (Resists bolt cutters) | ★☆ (Can be cut easily) | ★★★ (Requires heavy tools) |

| Visibility | Very high (Clear Sightlines) | Medium | Low |

| Corrosion Protection | Hot dip galv. & powder coated | Galvanized or plain steel | Painted, sometimes galvanized |

| Service Life (years) | 20~30+ | 8~15 | 12~18 |

| Maintenance Cost | Low | Medium | Medium |

| Compliance | ISO/EN/ANSI/ASTM certified | Limited (varies) | Some standards |

| Suitable Applications | Critical, high-security | Low/medium security | Medium security, industrial |

6. Applications & Typical Case Studies

The versatility and trusted performance of 358 Anti Climb Welded Wire Mesh Fence have led to its adoption in a wide range of fields:

- Petrochemical & Refinery perimeter security (exceeds API 1104 fencing recommendations)

- Corrections & Detention Centers (meeting ASTM F2781 for anti-intrusion)

- Metallurgical complexes & storage yards

- Water treatment and pump stations (with anti-corrosive guarantees)

- Urban & Mass Transit rail fencing (EN 13241 compliant)

- Airport & Border fencing

Case 1: International Airport Perimeter (Middle East)

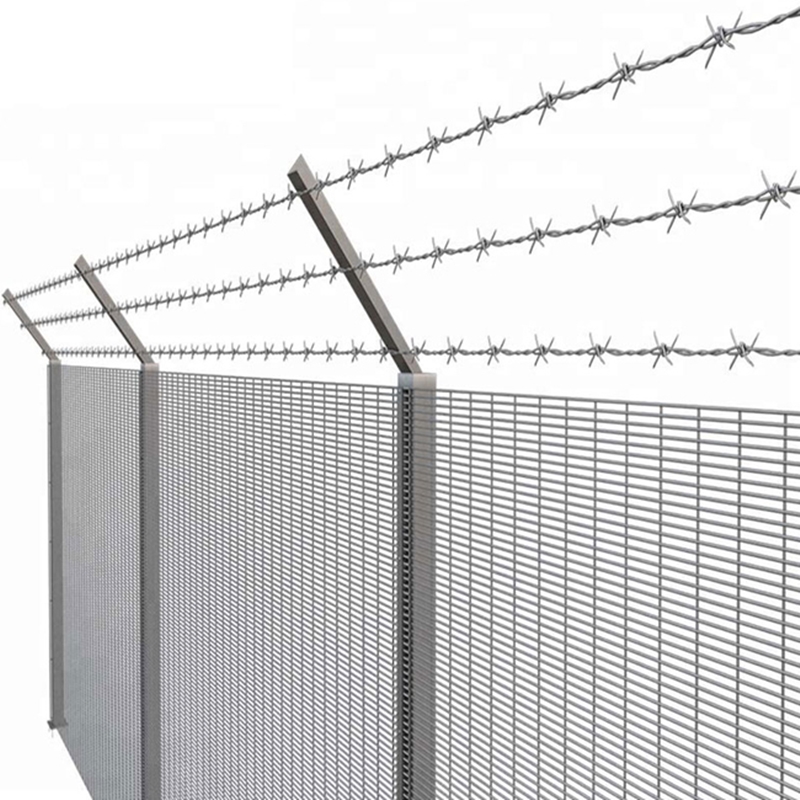

- Fence Supplied: 5,600m 358 Anti Climb Welded Wire Mesh Fence, 2.7m high, powder coated, with razor coil integration.

- Key Outcome: Zero perimeter breaches in 7 years, minimal maintenance downtime; authenticated by ICAO standards.

Case 2: Chemical Plant Security Upgrade (Europe)

- Delivery: Custom fence panels, 3.2m tall, hot dip galvanized, certified to ISO 1461.

- Result: Enhanced perimeter resilience and compliance with new ISO 28000 plant security standards.

Case 3: Correctional Institution Redevelopment (USA)

- Spec: Tamper-proof posts, welded at triple points; project met ANSI/ASTM F2781 requirements.

- Feedback: "The 358 Anti Climb Welded Wire Mesh Fence system performed beyond intrusion expectations during annual security drills." – U.S. Corrections Security Director

7. Custom Solutions

- Panel Height: 2.0m – 5.2m (additional anti-climb toppings on request)

- Coating Color: RAL7016, RAL6005, RAL9006 or custom per project branding

- Post Options: Square, RHS, I-Beam, with tamper-resistant fasteners

- Integration: Detection wires, anti-dig skirt, electronic alarms, CCTV mounting

- Gate & Access: Manual & automated gates in compatible mesh

- Packaging: Export standard, eco-friendlier as per ISO 14001

8. Authority, Certifications & Partners

-

Certifications:

- ISO 9001 (Quality Systems), ISO 1461 (Hot Dip Galv.), ISO 9227 (Corrosion Testing),

- ANSI/ASTM F1043, F2781, EN 10223-7, CE

- Notable Projects: Collaborative deliveries to government agencies, major oil & gas enterprises (e.g., Sinopec, Total), metro authorities, airports, correctional networks.

- Manufacturing Experience: 15+ years, supplying to 40+ countries.

- References: ISO Standards for Welded Fences, ASTM F2781: Anti-Climb Fencing Standard

9. Delivery, Warranty & Support

- Lead Time: Standard 15–25 days after order confirmation; urgent orders negotiable.

- Warranty: 10 years (coating guarantee), with lifetime technical support.

- Technical Support: Project consultation, on-site guidance, after-sales troubleshooting within 12 hours.

- Logistics: Global delivery, export-compliant packaging, on-time performance track record of 98.5% (2023 Data).

10. FAQs: Professional Q&A on 358 Anti Climb Welded Wire Mesh Fence

1. Which wire material grades are available for 358 Anti Climb Welded Wire Mesh Fence panels?

Most commonly: Q195, Q235, or stainless steel (AISI 304/316) for highly corrosive environments. All materials conform to ISO 6892-1 tensile and chemical requirements.

2. What are the typical mesh aperture and wire gauge specifications?

Industry standard is 76.2mm x 12.7mm (3" x 0.5") mesh opening with 4.0mm (8-gauge) wire; other options: 5.0mm and 6.0mm for ultra-high security per ASTM F1043.

3. What are the main surface treatment processes?

1. Pre-galvanizing, 2. Hot dip galvanizing (to ISO 1461 standard), 3. Polyester powder coating (to BS EN 13438), with total coating thickness typically 60–100μm.

4. What post types and fixing systems can be used?

RHS posts (60×60mm, 80×80mm), C-section, or custom profiles, fixed with stainless steel security bolts/shear nuts and anti-vandal brackets.

5. Is on-site customization available for irregular terrain or slopes?

Yes. Sloping panels, stepped installations, and variable-height posts are engineered on demand, maintaining all anti-climb properties even on rough ground.

6. How is the fence’s anti-corrosion performance validated?

All panels are subjected to 500–1,000 hours salt-spray and humidity tests per ISO 9227; test reports are available for every batch.

7. What is the installation standard for security facilities?

Installation is performed per ASTM F2781 & EN 10223-7 guidelines—requiring robust, tamper-resistant fasteners, post-anchoring to concrete, and double perimeter checks.

11. Why Choose 358 Anti Climb Welded Wire Mesh Fence?

358 Anti Climb Welded Wire Mesh Fence delivers unparalleled protection against climbing, cutting, and forced entry—proven in some of the world’s most demanding locations. Consistently manufactured to international standards, fully traceable, and supported by actionable customer feedback and performance data, it remains the number one choice for professional, secure perimeters.

- Industry-leading partners and supply history

- Certified to ISO, ANSI, EN, ASTM norms

- Responsive, export-focused technical and project support

To discuss your project or receive a technical drawing, contact our expert team directly via 358 Anti Climb Welded Wire Mesh Fence official page.

References & Further Reading

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025