Oct . 27, 2025 10:15 Back to list

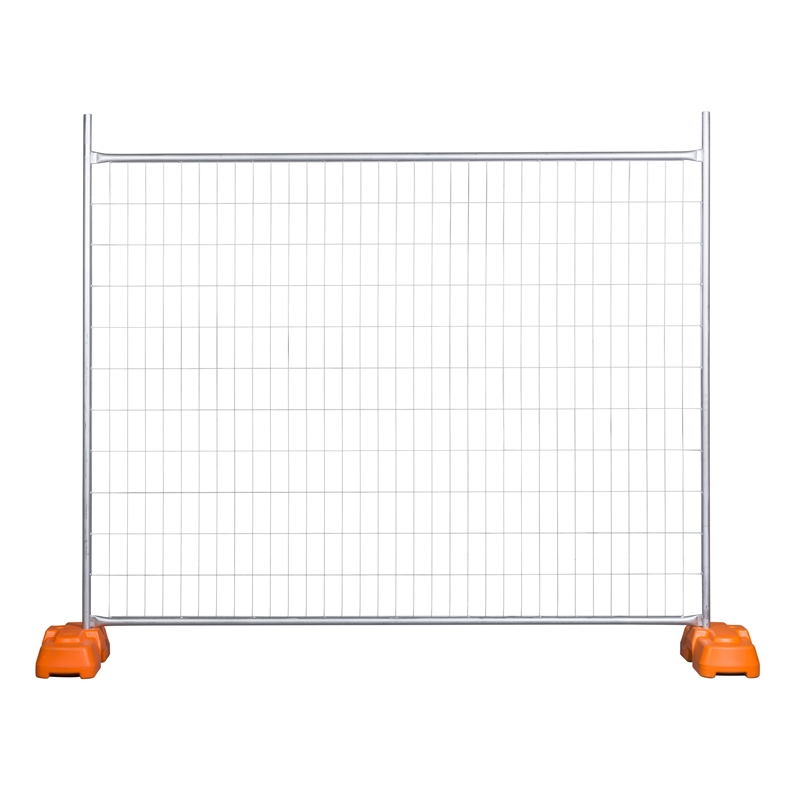

Hop Dipped Galvanized /PVC Coated Temporary Fence | Durable

Hop Dipped Galvanized /PVC Coated Temporary Fence: field notes from sites that never sleep

I’ve walked more muddy job sites than I can count, from wind-swept ports to pop-up festivals. One thing that keeps turning up—because it just works—is the Hop Dipped Galvanized /PVC Coated Temporary Fence. It’s a straightforward workhorse made in Anping, Hebei (200 meters north of Huangcheng Village, if you like exactness), yet the devil is in the details: steel grade, weld quality, and the coating that decides whether it lasts a season or a decade.

What the market is asking for (and why)

Across rental fleets, I’m seeing a pivot to longer-life coatings, safer bases, and tighter mesh to discourage footholds. ESG buyers push for service life transparency; safety managers cite AS 4687-style performance; and procurement wants interchangeability. To be honest, durability per dollar wins—hot-dip galvanizing with a PVC overlay is trending because it rides out salt spray and rough handling.

Core specifications (real-world, not brochure-only)

| Parameter | Typical Range (≈, may vary) |

|---|---|

| Material | Q195 or Q235 low-carbon steel |

| Panel size | ≈ 2.1 m (H) × 2.4 m (W) or per order |

| Mesh aperture | 60×150 mm to 75×150 mm |

| Wire diameter | 3.0–4.0 mm |

| Frame tube | Ø32 mm × 1.5–2.0 mm wall |

| Surface | Electro-galv (8–12 µm), Hot-dip galv (40–85 µm, ISO 1461), PVC coat (100–300 µm, EN 10244) |

| Bases & clamps | Recycled plastic/concrete-filled bases; anti-tamper clamps |

| Certifications | ISO 9001 (factory QMS) |

How it’s made (and tested)

Materials: Q195 for easier forming, Q235 when you want a stiffer frame. Panels are cut, CO2 MIG welded to frames, corners fish-plated, spatter ground smooth—small stuff that matters. Surface prep includes degrease, pickling, rinse, flux; then hot-dip galvanizing to ISO 1461/ASTM A123. PVC coating (if specified) follows phosphating and electrostatic application.

Testing: salt spray (ASTM B117) ≈ 500–1,000 h for PVC-over-galv; cross-hatch adhesion ISO 2409 class 0–1; weld shear checks; panel deflection under lateral load. Many buyers benchmark against AS 4687 for temporary fencing impact and wind stability. Real service life? Around 10–15 years coastal, 15–20 years inland for hot-dip galv; PVC adds chip resistance—your mileage may vary.

Where it works best

Construction perimeters, roadworks, industrial platforms, ports, mining laydown yards, festivals, even crowd channels for stadiums. Color-coded PVC (safety orange, company green) helps with branding and visibility; hot-dip galv is the default for harsh weather.

Why teams pick it

- Corrosion resistance that survives constant craning and re-stacking.

- Modular setup—fast clamps, stable bases, low training curve.

- Customization: gate panels, bracing, anti-climb mesh, reflective sleeves.

Vendor snapshot (what buyers compare)

| Vendor | Coating (≈) | Weld/Frame | Lead time | Best for |

|---|---|---|---|---|

| XZ Metal (Anping) | HDG 60–85 µm; PVC 120–250 µm | CO2 MIG; Ø32×2.0 mm optional | 3–5 weeks | Rental fleets, coastal |

| Regional importer | HDG ≈ 50 µm | Spot/MIG; Ø32×1.5 mm | Stock/quick | Events, short-term |

| Budget supplier | Electro-galv 8–12 µm | Spot weld; Ø25–32×1.2 mm | 2–4 weeks | Indoor/low-corrosion |

Customization and a couple of real cases

Options: mesh 50×100 mm for anti-climb, hand gates, bolt-down plates, powder/PVC color, and numbered tags for fleet control. One coastal wind farm upgraded to Hop Dipped Galvanized /PVC Coated Temporary Fence with extra bracing; their maintenance team told me corrosion checks dropped by half over two years. A festival operator liked the low-profile bases—fewer trip incidents, which, frankly, keeps insurers calm.

Bottom line

If you need panels that survive rehires and rough weather, the Hop Dipped Galvanized /PVC Coated Temporary Fence hits a pragmatic sweet spot: ISO 9001-backed build, coatings aligned with ISO 1461 and EN 10244 norms, and specs that can be tuned for your site reality.

Authoritative citations

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — https://www.iso.org/standard/61725.html

- ASTM A123/A123M: Zinc (Hot-Dip Galvanized) Coatings — https://www.astm.org/a0123_a0123m-17.html

- AS 4687: Temporary fencing and hoardings (overview) — https://infostore.saiglobal.com/en-au/standards/as-4687-2007-120904/

- EN 10244: Steel wire and wire products — Non-ferrous metallic coatings on steel wire — https://standards.iteh.ai/catalog/standards/cen/3e6b0b0e-

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025