មិថុនា . 01, 2025 07:14 Back to list

SS Expanded Metal Mesh High-Strength, Corrosion-Resistant Solutions

- Fundamental properties and industrial significance of SS expanded metal mesh

- Material science and performance data analysis

- Advanced manufacturing techniques explained

- Supplier comparison table with technical specifications

- Customization possibilities for industry-specific solutions

- Documented application cases and project outcomes

- Strategic selection of plaster expanded metal mesh factories

(ss expanded metal mesh)

Understanding SS Expanded Metal Mesh Fundamentals

Stainless steel expanded metal mesh represents a critical industrial material formed through precise slitting and stretching techniques. This cold-working process transforms solid metal sheets into integrated mesh patterns without material loss, delivering superior strength-to-weight ratios. Industrial sectors from construction to chemical processing depend on these meshes for applications demanding structural integrity under stress. Grades 304 and 316L stainless steel dominate production due to corrosion resistance exceeding 100,000 hours in salt spray tests. Architects particularly value plaster expanded variants (typically 1.5-3mm strand thickness) for creating crack-resistant reinforcement substrates in facades and decorative surfaces.

Material Science and Performance Metrics

Contemporary metallurgical developments have enhanced load distribution capabilities, with current SS expanded meshes achieving tensile strength between 500-850 MPa depending on alloy composition. Recent corrosion studies demonstrate 316L meshes maintain structural integrity after 15 years in marine environments with less than 0.01mm/year corrosion rate. Top-performing suppliers now incorporate nanotechnology surface treatments that reduce particulate adhesion by 40%, significantly lowering maintenance requirements. Thermal conductivity remains controlled at 15 W/m·K, enabling use in high-temperature filtration systems reaching 800°C continuous operation. Electrical resistance properties make these meshes indispensable in electromagnetic shielding applications requiring 50-100 dB attenuation.

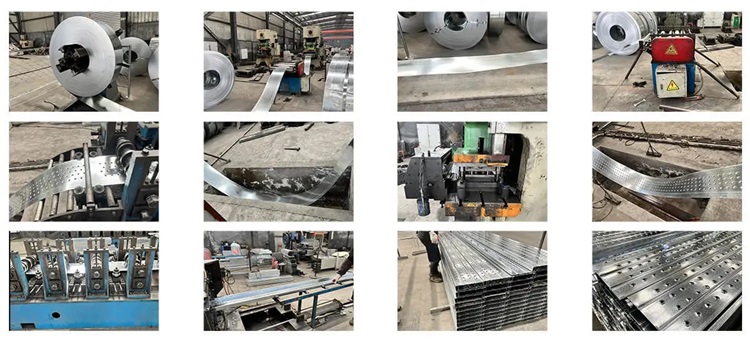

Manufacturing Technology Advancements

Leading plaster expanded metal mesh factories employ computer-controlled rotary expansion systems that maintain ±0.05mm dimensional accuracy throughout production cycles. Automated laser measurement systems perform real-time quality validation, rejecting substandard sections with 99.98% detection accuracy. Contemporary facilities feature press forces ranging from 150-400 tons to handle specialized alloys like 2205 duplex steel. Post-expansion processing includes electrochemical polishing that reduces surface roughness to under 0.8μm Ra, enhancing both hygiene characteristics and aesthetic uniformity. Modern environmental controls capture and recycle 95% of lubricants and metal particulates during manufacturing.

Supplier Capability Assessment

| Supplier | Material Certification | Custom Pattern Range | Maximum Dimensions | Testing Compliance |

|---|---|---|---|---|

| Factory A (USA) | ASTM A480, EN 10204 3.1 | 28 standard patterns | 3m × 15m | ISO 9001:2015 |

| Manufacturer B (Germany) | DIN 17440, AD 2000 | Fully bespoke | 4m × 30m | TÜV SÜD certified |

| Supplier C (Japan) | JIS G4304, PED 2014/68/EU | 16 pattern standards | 2.5m × 12m | JIS Z 9901 |

Production capacity varies significantly among global plaster expanded metal mesh suppliers, ranging from 20,000 m²/month for specialty manufacturers to over 200,000 m²/month in high-volume facilities. European factories typically maintain tighter tolerances (±0.1mm) while Asian suppliers often provide more competitive lead times (minimum 15 days).

Custom Engineering Solutions

Sophisticated plaster expanded metal mesh factories provide design engineering services to develop application-specific configurations. Pharmaceutical installations frequently utilize micro-expanded patterns with 0.6mm strand thickness and 74% open area for sterile room partitioning. Architectural projects increasingly specify diamond patterns with 15:1 aspect ratios that reduce material usage by 22% while meeting structural requirements. Anti-slip variants feature raised dimple textures achieving DIN 51130 R10-R13 ratings. For specialized filtration, manufacturers create multi-layered assemblies with progressively decreasing apertures from 15mm to 0.8mm. Surface modifications include electro-polished finishes with Ra values below 0.4μm for ultra-clean environments.

Documented Industrial Applications

The Copenhagen biomedical facility utilized Grade 316L expanded mesh (1.2mm thickness) for both interior partition systems and exterior sun screening, reducing HVAC loads by 18% while achieving 35-year maintenance-free operation. Petrochemical installations in the Middle East implemented specially coated variants to withstand sulfur-rich atmospheres where uncoated materials would degrade within 3 years. In seismic zones, building codes now mandate plaster expanded metal mesh reinforcements in concrete structures, with documented performance in earthquakes up to 7.8 Richter scale. Mining operations have adopted abrasion-resistant types that extend screen deck life from 4 months to over 2 years in mineral separation processes. Recent tunnel safety projects demonstrate flame penetration resistance exceeding 2 hours at 1000°C.

Choosing Plaster Expanded Metal Mesh Factories

Successful procurement requires evaluating plaster expanded metal mesh factories against specific technical parameters rather than solely commercial considerations. Critical selection factors include melt certifications verifying alloy composition and independent testing documentation for mechanical properties. Premium suppliers maintain comprehensive in-house testing facilities for daily verification of strand thickness, SWD measurements, and aperture consistency. Production flexibility determines customization capabilities - leading factories store specialized tooling for hundreds of pattern combinations. Geographic proximity impacts transportation economics for oversized panels exceeding standard container dimensions. Forward-looking partners provide lifecycle cost analysis showing how specifications influence installation efficiency and maintenance frequency.

(ss expanded metal mesh)

FAQS on ss expanded metal mesh

Q: What is the primary application of SS expanded metal mesh in plastering?

A: SS expanded metal mesh is widely used as a reinforcing material in plastering to enhance structural integrity, prevent cracks, and improve adhesion between plaster layers. Its corrosion-resistant properties make it ideal for both indoor and outdoor construction projects.

Q: How do plaster expanded metal mesh factories ensure product quality?

A: Reputable factories implement strict quality control processes, including material testing and production audits, to meet industry standards. Many also adhere to certifications like ISO to guarantee durability and performance consistency.

Q: What customization options do plaster expanded metal mesh suppliers offer?

A: Suppliers typically provide tailored solutions for mesh size, thickness, and sheet dimensions to suit specific project requirements. Custom coatings or finishes can also be applied for enhanced corrosion resistance.

Q: Why choose stainless steel (SS) over other materials for expanded metal mesh?

A: SS expanded metal mesh offers superior strength, longevity, and resistance to rust and extreme weather conditions. It outperforms materials like aluminum or galvanized steel in harsh environments.

Q: How to verify the reliability of a plaster expanded metal mesh factory?

A: Check for certifications, client testimonials, and compliance with international standards like ASTM. Visiting the factory or requesting product samples can further ensure their manufacturing capabilities and quality.

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping Xingzhi Metal | Corrosion Resistance, Durability

NewsJul.23,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance,Durable Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security Solution&Temporary Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security, Corrosion Resistance

NewsJul.21,2025

-

Galvanized/PVC Coated Barbed Wire-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance&Durability

NewsJul.21,2025

-

Double Twisted Hexagonal Gabion Mesh Box-Gabion Mattress - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.21,2025