Sep . 03, 2025 13:40 Back to list

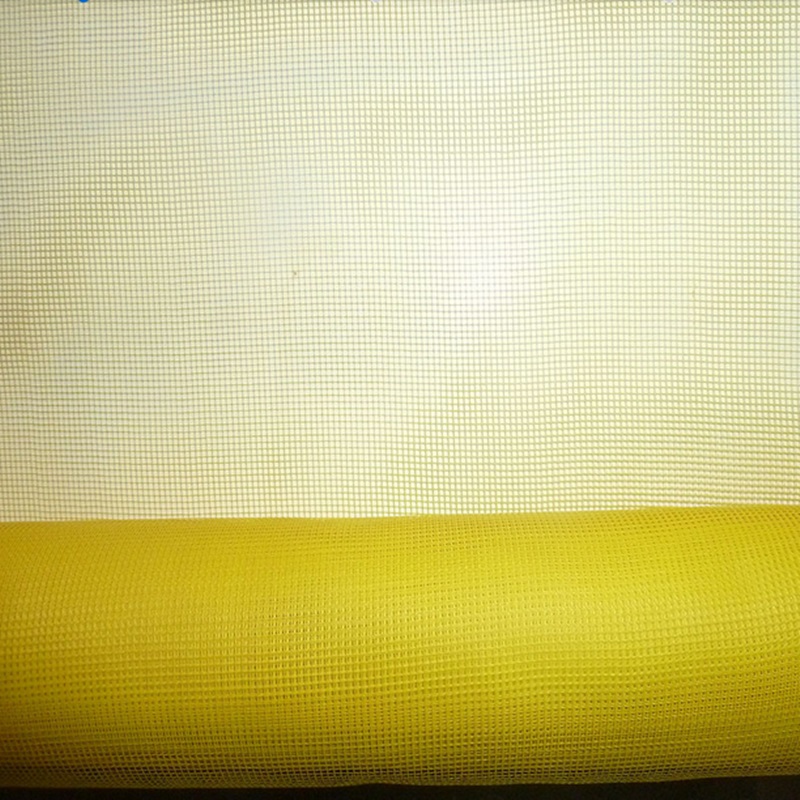

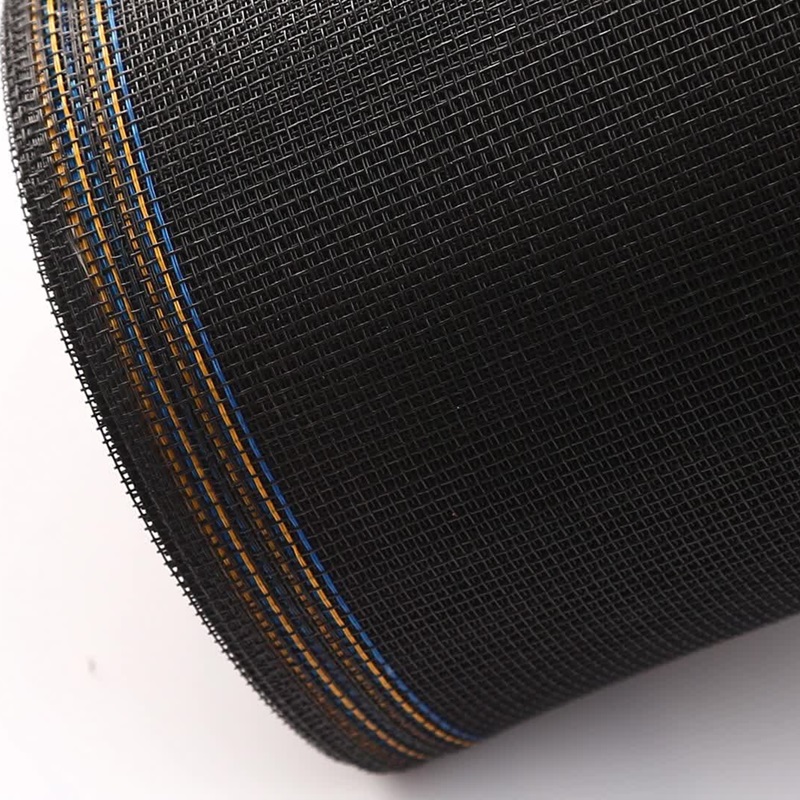

Durable Plastic Window Screen & Insect Mesh | Keep Bugs Out

Introduction to Plastic Window Screen and Insect Mesh Solutions

In modern construction, agriculture, and various industrial applications, the demand for effective and durable screening solutions is paramount. Among the leading choices, Plastic window screen/plastic insect mesh stands out for its versatility, resilience, and cost-effectiveness. This material, typically manufactured from high-density polyethylene (HDPE), polypropylene (PP), or fiberglass coated with PVC, offers superior protection against insects, debris, and UV radiation, while ensuring optimal airflow and light transmission. Its lightweight nature, coupled with remarkable chemical resistance and ease of installation, makes it an indispensable component in a wide array of settings. As industries evolve and environmental considerations become more critical, the engineering and material science behind these meshes continue to advance, providing increasingly specialized and high-performance solutions for discerning B2B clients.

Industry Trends and Market Outlook for Polymer-Based Screening

The market for polymer-based screening, particularly plastic window screen/plastic insect mesh, is experiencing robust growth driven by several key trends. Global urbanization and the increasing demand for pest control solutions in both residential and commercial sectors are primary catalysts. There's a noticeable shift towards sustainable and durable materials, with manufacturers focusing on enhanced UV resistance, fire retardancy, and improved structural integrity to extend product service life. Furthermore, the rise of smart building technologies and integrated pest management (IPM) systems is creating new opportunities for specialized mesh products, including those with finer weaves for micro-insect protection or electrostatic properties.

Technological advancements in polymer extrusion and weaving processes are leading to the production of meshes with consistent aperture sizes, higher tensile strength, and greater uniformity, catering to stringent industry specifications. The agricultural sector, in particular, is witnessing increased adoption for greenhouse shading, insect exclusion in crop protection, and aquaculture applications, driven by the need for higher yields and reduced pesticide usage. Regionally, growth is significant in Asia-Pacific due to rapid construction and infrastructure development, while North America and Europe continue to focus on premium, long-lasting, and environmentally compliant solutions. Market projections indicate a sustained compound annual growth rate (CAGR) of approximately 4-6% over the next five years, emphasizing the critical role these materials play across diverse industries.

Materials and Manufacturing Process of Plastic Insect Mesh

Core Materials and Their Properties

The efficacy and longevity of plastic window screen/plastic insect mesh are fundamentally determined by its constituent materials. Common polymers include:

- High-Density Polyethylene (HDPE): Renowned for its excellent strength-to-density ratio, chemical resistance, and UV stability. HDPE meshes are lightweight yet durable, making them ideal for agricultural and general screening.

- Polypropylene (PP): Offers good tensile strength, resistance to fatigue, and is often used where flexibility and chemical inertness are critical.

- PVC Coated Fiberglass: Provides superior dimensional stability, fire resistance, and a higher level of rigidity. The PVC coating enhances durability, UV resistance, and makes the mesh resistant to shrinking and stretching, commonly used in high-traffic architectural applications.

- Nylon: Known for its strength, elasticity, and resistance to abrasion. Often used for specialized filtration or heavy-duty screening where impact resistance is a factor.

Manufacturing Process Flow

The production of high-quality plastic window screen/plastic insect mesh involves a meticulously controlled multi-stage process, ensuring consistent product specifications and performance.

-

Material Preparation & Extrusion:

High-grade polymer granules (HDPE, PP, or fiberglass yarn for PVC coating) are carefully selected. These are then fed into an extruder, where they are melted and forced through a die to form continuous filaments of precise diameter. Additives such as UV stabilizers, colorants, and fire retardants are incorporated at this stage to enhance material properties. For fiberglass mesh, fiberglass strands are initially woven and then coated with liquid PVC.

-

Weaving/Knitting:

The extruded filaments are spooled onto bobbins and fed into specialized weaving looms (for woven mesh) or knitting machines (for knitted mesh). The most common weave patterns are plain weave or leno weave, chosen for their structural stability and consistent aperture size. This critical step determines the mesh count, wire diameter, and overall porosity, which directly impacts airflow, light transmission, and insect exclusion capabilities.

-

Heat Setting & Finishing:

After weaving, the mesh undergoes a heat-setting process. This stabilizes the fabric, preventing unraveling, reducing shrinkage, and improving dimensional stability. For PVC-coated fiberglass mesh, the curing of the PVC also takes place. Further finishing steps may include edge reinforcement, anti-microbial treatments, or additional UV protection layers depending on the application.

-

Quality Control & Testing:

Each batch undergoes rigorous quality control. Testing standards include ISO 9001 for quality management, tensile strength (ASTM D5034, ASTM D751), tear resistance, burst strength, UV degradation resistance (ASTM G154), and consistent aperture size measurement. Visual inspections ensure no defects, inconsistencies, or foreign matter are present.

-

Cutting & Packaging:

The finished mesh is then cut to specified dimensions (rolls, sheets) and carefully packaged to prevent damage during transit, ensuring it arrives at the client's site in optimal condition.

This meticulous process ensures that each roll of plastic window screen/plastic insect mesh meets the highest industry standards for performance and durability, providing a reliable solution for various demanding applications. The service life of these meshes typically ranges from 5 to 15 years, depending on the material, exposure to environmental factors, and specific additives used during manufacturing.

Technical Specifications and Performance Parameters

Understanding the detailed technical specifications is crucial for selecting the appropriate plastic window screen/plastic insect mesh for a given application. Key parameters include mesh count, wire diameter, aperture size, material composition, and various performance metrics.

Typical Product Specification Table

Material Comparison: HDPE vs. PVC Coated Fiberglass

Technical Advantages of Plastic Window Screen/Insect Mesh

The engineered properties of plastic window screen/plastic insect mesh offer a compelling suite of advantages that address critical needs across various industries:

- Superior Corrosion Resistance: Unlike traditional metal screens, plastic mesh is inherently resistant to rust, oxidation, and most chemical agents, including acids, alkalis, and salts. This makes it ideal for coastal environments, industrial settings (e.g., petrochemical facilities for vent screening), and agricultural applications where exposure to fertilizers or pesticides is common. This significantly extends its service life in harsh conditions.

- Lightweight and Enhanced Durability: Despite its light weight, modern plastic meshes exhibit impressive tensile strength and tear resistance. This characteristic reduces structural load on frames and simplifies handling and installation, while specialized manufacturing techniques ensure the mesh can withstand environmental stresses, impact, and prolonged use without degradation.

- Cost-Effectiveness and Low Maintenance: The initial investment in plastic mesh is often lower than that for comparable metal alloys. Furthermore, its resistance to corrosion and minimal need for painting or specialized cleaning translates into significant long-term savings on maintenance and replacement costs.

- Excellent UV Stability: Advanced polymer formulations include integrated UV inhibitors that prevent material degradation, embrittlement, and color fading when exposed to prolonged sunlight. This ensures the mesh retains its physical integrity and aesthetic appeal for many years, even in intense solar radiation zones.

- Optimal Airflow and Visibility: Precision weaving ensures consistent aperture sizes, allowing for maximum airflow and light transmission while effectively blocking insects and debris. This property is crucial for maintaining comfortable indoor environments, supporting healthy plant growth in greenhouses, and ensuring clear visibility in window applications.

- Energy Saving Benefits: By facilitating natural ventilation, plastic insect mesh can reduce reliance on air conditioning, contributing to energy efficiency in buildings. In agricultural settings, optimal airflow helps regulate temperature and humidity, promoting plant health and potentially reducing energy consumption for environmental controls.

These technical advantages underscore why plastic window and insect meshes are increasingly preferred by specifiers and purchasers seeking reliable, high-performance, and economically viable screening solutions.

Application Scenarios and Target Industries

The versatility of plastic window screen/plastic insect mesh extends its utility across a broad spectrum of industries, providing essential protection and functional benefits.

Residential and Commercial Construction

- Window and Door Screens: The most common application, providing effective insect barrier while maintaining ventilation. PVC coated fiberglass meshes are highly favored for their durability and clear visibility.

- Porch and Patio Enclosures: Creating comfortable, pest-free outdoor living spaces.

- Soffit and Attic Vent Screens: Preventing insect and rodent entry into building ventilation systems, crucial for maintaining air quality and structural integrity.

- Rain Gutter Protection: Keeping leaves and debris out of gutters, preventing clogs and water damage.

Agriculture and Horticulture

- Greenhouse Sidewalls and Roof Vents: Essential for pest exclusion, creating a protected environment for crops without hindering airflow. Finer meshes also offer light shading, reducing heat stress on plants.

- Crop Protection Nettings: Directly covering vulnerable crops to prevent insect damage, bird predation, and hail, supporting organic farming practices by reducing pesticide use.

- Aquaculture: Used in fish farming for predator exclusion and water filtration.

- Seedling Trays and Nursery Beds: Protecting young plants from pests while allowing proper drainage and air circulation.

Industrial and Special Applications

- Filtration: Used in various industrial filters for coarse particle separation, air filtration, and liquid processing, especially where chemical resistance is required.

- Safety Barriers and Netting: Lightweight temporary fencing, material containment, or safety netting on construction sites.

- Water Supply & Drainage: Screening for intake pipes, drains, and overflow systems to prevent blockages from debris while allowing water flow.

- Petrochemical and Chemical Plants: For vent screens, barrier nets, or non-corrosive separation tasks where metallic options would degrade.

Customized Solutions for Specialized Requirements

Recognizing that standard products may not always meet unique project demands, leading manufacturers offer extensive customization options for plastic window screen/plastic insect mesh. These bespoke solutions ensure optimal performance and integration for specific applications.

- Tailored Mesh Count and Aperture Size: From ultra-fine meshes (e.g., 50x50 per inch) for blocking tiny gnats and thrips in specialized greenhouses to coarser weaves for ventilation or debris screening, the mesh parameters can be precisely adjusted.

- Material Blends and Additives: Custom formulations can incorporate specific additives such as enhanced UV stabilizers for extreme climates, anti-microbial agents for hygiene-sensitive environments (e.g., food processing), flame retardants for fire safety compliance, or anti-static properties.

- Color and Aesthetic Matching: For architectural or branding purposes, meshes can be produced in a wide range of colors to blend seamlessly with building facades or stand out as a design element.

- Specific Dimensions and Roll Lengths: Manufacturers can provide custom widths and lengths to minimize waste and streamline installation for large-scale projects, such as commercial building complexes or extensive agricultural operations.

- Edge Treatment and Reinforcement: Specialized edge treatments, such as heat-sealed or reinforced selvages, can be applied to prevent fraying and provide additional strength for tensioned applications or frequent handling.

Partnering with a manufacturer capable of delivering these customized solutions ensures that clients receive a product perfectly aligned with their project's technical and operational requirements, leading to superior performance and long-term satisfaction.

Vendor Comparison: Key Factors for Selection

Choosing the right vendor for plastic window screen/plastic insect mesh is critical for ensuring product quality, reliability, and project success. B2B decision-makers should evaluate potential suppliers based on a comprehensive set of criteria beyond just pricing.

- Manufacturing Expertise and Technology: Assess the vendor's production capabilities, including the use of advanced extrusion and weaving equipment, quality control systems, and adherence to international manufacturing standards (e.g., ISO 9001).

- Material Quality and Sourcing: Inquire about the source and grade of raw polymers, ensuring they are virgin materials and not recycled content unless explicitly specified. Transparency in material data sheets (MDS) is crucial.

- Product Range and Customization: A reputable vendor should offer a diverse portfolio of mesh types (HDPE, PVC Coated Fiberglass, various mesh counts) and the flexibility to provide customized solutions for unique project requirements.

- Certifications and Compliance: Verify relevant product certifications (e.g., UV stability testing, fire ratings, chemical resistance reports) and adherence to industry standards (ASTM, ANSI, EN). This demonstrates commitment to quality and safety.

- Lead Times and Logistics: Evaluate the vendor's capacity to meet specified lead times, their logistical capabilities for timely delivery, and their ability to handle large volume orders efficiently.

- Technical Support and After-Sales Service: Strong technical support, including assistance with product selection, installation guidance, and a clear warranty policy, is indicative of a reliable long-term partner.

- Reputation and Client References: Review industry reputation, customer testimonials, and case studies. Requesting references from other B2B clients can provide valuable insights into a vendor's reliability and service quality.

Application Case Studies: Real-World Impact

Case Study 1: Large-Scale Agricultural Greenhouse Complex

Client: AgroTech Innovations, a leading commercial greenhouse operator specializing in organic vegetable production.

Challenge: The client faced significant crop losses due to an increasing prevalence of whiteflies and thrips, requiring frequent and costly applications of organic pesticides. Traditional mesh screens were prone to tearing and had inconsistent aperture sizes, compromising pest exclusion.

Solution: Implementation of a custom-designed 32x32 mesh count HDPE plastic insect mesh, incorporating enhanced UV stabilizers and a specialized anti-thrip weave pattern. This mesh was installed on all sidewall and roof vents across 10 hectares of greenhouse space.

Results: Within six months, pest incidence decreased by over 85%, leading to a 70% reduction in pesticide usage. Crop yield increased by 15% due to reduced pest damage and improved microclimate control. The mesh's durability withstood severe weather conditions, demonstrating a projected service life exceeding 10 years, significantly reducing replacement costs.

Case Study 2: Coastal Residential Development

Client: Oceanfront Estates Development, constructing high-end residential properties in a hurricane-prone coastal region.

Challenge: Standard aluminum screens quickly corroded due to saltwater exposure and offered insufficient protection against strong winds and insect ingress common in tropical environments. The aesthetic requirement for clear, unobstructed views was also paramount.

Solution: High-tensile PVC coated fiberglass plastic window screen/plastic insect mesh (18x16 mesh count) was specified for all windows, doors, and screened-in patios. This material offered superior corrosion resistance, excellent dimensional stability, and passed ASTM D751 tear resistance tests far exceeding local building codes. Its charcoal color provided minimal visual obstruction.

Results: After five years, screens showed no signs of corrosion or degradation, a stark contrast to previous projects using metallic meshes. Resident feedback highlighted superior insect protection without compromising ocean views. The enhanced durability reduced property management's maintenance burden by 90% compared to previous installations.

Commitment to Excellence: Authoritativeness and Trustworthiness

Certifications and Quality Assurance

Our manufacturing processes for plastic window screen/plastic insect mesh adhere to stringent international quality management standards, including ISO 9001:2015. Each product batch undergoes comprehensive testing in accordance with relevant ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) protocols for tensile strength, tear resistance, UV stability, and dimensional consistency. We provide Certificates of Conformance (CoC) and detailed test reports upon request, ensuring complete transparency and compliance for our B2B partners. Our consistent track record spans over two decades, serving a global client base that includes major construction firms, agricultural enterprises, and industrial suppliers.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for bulk orders?

A: Standard orders typically have a lead time of 2-4 weeks. For custom specifications or very large volumes, lead times may vary, and a detailed schedule will be provided upon order confirmation. Expedited options are available upon request. - Q: What warranty is offered on your plastic mesh products?

A: We provide a comprehensive 5-10 year limited warranty against manufacturing defects and premature degradation under normal use, depending on the specific product line and material. Full warranty details are available in our product documentation. - Q: Can your mesh products be used in extreme temperatures?

A: Yes, our specialized polymer formulations and PVC coatings are designed to perform reliably across a broad temperature range, typically from -40°C to +120°C, ensuring integrity in diverse climatic conditions. - Q: How do you handle customer support and technical inquiries?

A: Our dedicated technical support team is available via phone and email during business hours to assist with product selection, technical specifications, installation guidance, and any post-purchase inquiries. We aim for a response time of under 24 hours for all technical questions.

Lead Time, Fulfillment, and Customer Support

We maintain robust production capabilities and a streamlined supply chain to ensure efficient fulfillment of orders, from small custom batches to large-scale industrial quantities. Our logistics team works closely with clients to coordinate shipping and delivery, aiming to meet project deadlines consistently. Post-sale, our commitment continues with dedicated customer service, ready to address any operational queries or offer further product optimization advice. Our goal is to forge long-term partnerships built on trust, quality, and mutual success.

Conclusion

The demand for high-performance plastic window screen/plastic insect mesh continues to expand across diverse B2B sectors, driven by its unparalleled combination of durability, chemical resistance, cost-effectiveness, and environmental adaptability. From safeguarding agricultural yields to enhancing modern architectural designs and ensuring efficient industrial processes, these polymer-based screening solutions offer a robust and versatile answer to complex engineering challenges. By focusing on advanced materials, precise manufacturing, and rigorous quality control, manufacturers deliver products that not only meet but exceed contemporary industry standards. As innovation in polymer science progresses, the capabilities of plastic mesh will only grow, solidifying its role as an essential component for effective protection and efficient resource management in a globalized economy.

References

- ISO. (2015). ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- ASTM International. (2020). ASTM D5034-20 - Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test).

- ASTM International. (2018). ASTM G154-16 - Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials.

- Polymer Science and Technology Journal. (Vol. 45, Issue 2). "Advances in Polymer Extrusion for Fine Filament Production."

- Journal of Agricultural Engineering Research. (Vol. 18, Issue 3). "Impact of Insect Netting on Microclimate and Pest Control in Greenhouse Cultivation."

- Building Materials Research & Application. (Vol. 12, Issue 4). "Durability Assessment of PVC Coated Fiberglass Mesh in Coastal Climates."

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025