Aug . 22, 2025 09:40 Back to list

Durable Double Twisted Hexagonal Gabion Mesh Roll for Erosion Control

Industry Trends in Erosion Control and Infrastructure

The global demand for robust and sustainable solutions in civil engineering, particularly in erosion control, slope stabilization, and hydraulic structures, continues its upward trajectory. Driven by increasing climate variability, urban expansion, and the need for resilient infrastructure, engineers and project managers are consistently seeking advanced materials that offer both efficacy and longevity. The market for geotechnical products is witnessing significant innovation, focusing on materials that provide superior strength-to-weight ratios, environmental compatibility, and ease of installation. Traditional construction methods are gradually being supplemented or replaced by engineered solutions that minimize environmental impact while maximizing structural integrity.

Key trends include the adoption of passive environmental protection systems, which integrate seamlessly with natural landscapes, and a heightened emphasis on material sustainability and lifecycle assessment. Products like the Double Twisted Hexagonal Gabion Mesh Roll are at the forefront of this evolution, offering a versatile, permeable, and durable solution that aligns perfectly with these modern engineering principles. The demand is particularly pronounced in coastal protection, river training, road and railway embankment stabilization, and mining site remediation, where resilience against hydrological forces and seismic activity is paramount.

Furthermore, the integration of advanced coating technologies, such as heavily galvanized and PVC-coated wires, is a critical trend enhancing the service life and performance of these meshes in aggressive environments. This technological progression ensures that infrastructure projects are not only initially robust but also maintain their structural and protective integrity over extended periods, reducing maintenance costs and ensuring public safety.

Manufacturing Process Flow of Double Twisted Hexagonal Gabion Mesh Roll

The production of a Double Twisted Hexagonal Gabion Mesh Roll involves a meticulous, multi-stage manufacturing process designed to ensure the highest standards of strength, durability, and corrosion resistance. Adherence to international quality standards such as ISO 9001 and specific material standards like ASTM A975-97 for steel wire and EN 10223-3 for gabions is crucial at every step. The process is optimized for target industries including civil engineering, environmental protection, mining, and agricultural sectors, offering a service life often exceeding 50 years under ideal conditions, thanks to superior material selection and protective coatings.

Detailed Process Steps:

- 1. Raw Material Sourcing & Inspection: High-quality, low-carbon steel wire (typically SAE 1006 or equivalent) with specified tensile strength (380-550 MPa) and elongation properties (minimum 10% for unannealed wire, 12% for annealed wire) is sourced. Each batch undergoes rigorous inspection for chemical composition, mechanical properties, and surface finish to ensure it meets international specifications for gabion wire. This initial stage is critical for the overall integrity and performance of the final product.

- 2. Wire Galvanization: The steel wire is then hot-dip galvanized. This process involves cleaning the wire thoroughly to remove impurities, immersing it in a bath of molten zinc (minimum 99.5% pure zinc), and then allowing it to cool. The zinc coating provides sacrificial cathodic protection against corrosion. Standard zinc coating weight typically ranges from 245 g/m² to 290 g/m² as per ASTM A641/A975, which significantly extends the material's service life, especially in aquatic or corrosive environments.

- 3. Optional PVC Coating (Polyvinyl Chloride): For applications in highly aggressive environments (e.g., saltwater, acidic soils), an additional layer of PVC coating is applied over the galvanized wire. This involves extruding a uniform layer of PVC onto the galvanized wire, which is then cured. The PVC coating (typically 0.5mm minimum thickness) offers exceptional resistance to chemical corrosion, abrasion, and UV radiation, further enhancing the lifespan and performance of the Double Twisted Hexagonal Gabion Mesh Roll in critical applications, demonstrating superior corrosion resistance compared to galvanized-only alternatives.

- 4. Weaving/Twisting Process: The coated wires are fed into specialized weaving machines that create the distinctive double-twisted hexagonal mesh pattern. This double-twist mechanism ensures that if one wire breaks, the integrity of the surrounding mesh remains largely unaffected, providing superior structural stability and anti-unraveling properties. The mesh sizes are precisely controlled (e.g., 60x80mm, 80x100mm, 100x120mm) to meet specific design requirements. This process is essentially a form of precise mechanical fabrication, akin to automated CNC machining in its control over dimensions.

- 5. Edging Wire Integration: Stronger diameter wires (typically 0.5mm to 1.0mm thicker than the mesh wire) are interwoven at the edges of the mesh roll to provide increased rigidity and structural integrity. This edging wire is crucial for maintaining the shape of the gabion unit when filled and for resisting deformation under load.

- 6. Rolling and Packaging: The continuous woven mesh is then carefully rolled into compact rolls of specified lengths (e.g., 25m, 50m) and widths, ready for transportation. Each roll is securely bound and labeled with product specifications and batch information. The rolls are designed for ease of handling and deployment on construction sites.

- 7. Quality Control & Testing: Throughout the entire process, rigorous quality control checks are performed. This includes tensile strength tests, zinc coating thickness measurements (using magnetic or eddy current gauges), PVC coating adhesion tests, mesh opening dimension verification, and visual inspections for defects. Compliance with ISO 9001 and specific product standards (e.g., ASTM, EN) ensures that every Double Twisted Hexagonal Gabion Mesh Roll meets stringent performance criteria for its intended applications, from energy saving through material efficiency to high corrosion resistance in critical water supply and drainage projects.

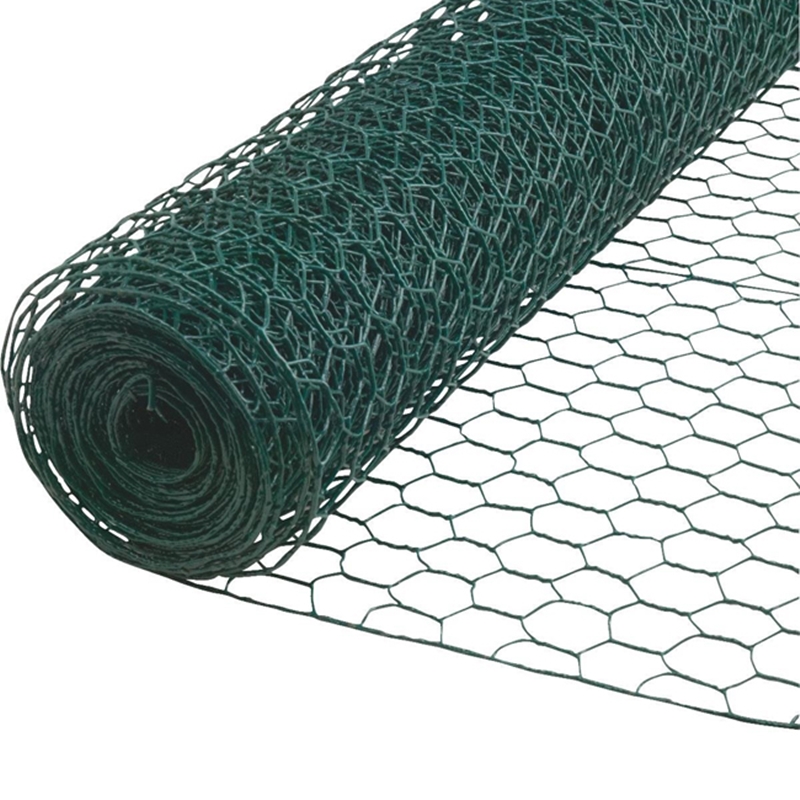

Figure 1: Illustration of the high-quality galvanized wire used in Double Twisted Hexagonal Gabion Mesh Roll production.

Technical Specifications and Parameters

The performance and suitability of a Double Twisted Hexagonal Gabion Mesh Roll for specific engineering projects are primarily dictated by its technical specifications. Understanding these parameters is crucial for ensuring structural integrity, longevity, and compliance with project requirements. Our products are engineered to exceed industry benchmarks, providing reliable solutions for demanding applications.

Standard Product Specifications:

| Parameter | Specification Range | Relevant Standard |

|---|---|---|

| Mesh Wire Diameter (D) | 2.0 mm – 4.0 mm | ASTM A641/A975, EN 10218-2 |

| Selvage/Edging Wire Diameter (D+0.5mm to D+1.0mm) | 2.7 mm – 4.5 mm | ASTM A641/A975, EN 10218-2 |

| Lacing/Tie Wire Diameter | 2.2 mm (commonly) | ASTM A641/A975 |

| Mesh Opening Size (Hexagonal) | 60x80 mm, 80x100 mm, 100x120 mm, 120x150 mm | EN 10223-3 |

| Tensile Strength of Wire | 380-550 MPa (55,000-80,000 psi) | ASTM A975, EN 10218-1 |

| Elongation at Break | ≥ 10% (galvanized), ≥ 7% (PVC coated) | ASTM A975, EN 10218-1 |

| Zinc Coating Weight (Hot-Dip Galvanized) | Min 245 g/m² (for wire D ≥ 2.7 mm) | ASTM A641/A975, EN 10244-2 |

| PVC Coating Thickness (Over Galvanization) | Min 0.5 mm | ASTM A975, EN 10223-3 |

| Roll Lengths (Typical) | 25m, 50m | Manufacturer Specific |

| Roll Widths (Typical) | 2m, 3m, 4m | Manufacturer Specific |

Figure 2: Close-up of a Double Twisted Hexagonal Gabion Mesh Roll showcasing the consistent hexagonal pattern.

These parameters, backed by rigorous internal and third-party testing, ensure that each Double Twisted Hexagonal Gabion Mesh Roll delivers superior geotechnical stability, excellent hydraulic performance, and exceptional environmental integration for various demanding projects. The combination of high tensile strength, significant elongation, and robust corrosion protection provides a durable, long-term solution.

Application Scenarios

The versatility and robustness of Double Twisted Hexagonal Gabion Mesh Roll make it an indispensable material across a broad spectrum of engineering and environmental applications. Its unique design allows it to adapt to ground movement, making it highly effective in dynamic environments. The permeability of gabion structures ensures natural drainage, mitigating hydrostatic pressure buildup behind retaining structures.

Key Application Areas:

- River Training and Flood Control: Gabion structures are widely used for river bank protection, weir construction, channel lining, and scour protection. Their ability to integrate with natural sediment deposition patterns helps restore ecological balance while preventing erosion.

- Slope Stabilization: As retaining walls, slope facings, and revetments, gabions provide effective stabilization for steep embankments along roads, railways, and construction sites, preventing landslides and soil erosion. The flexibility of the mesh allows it to conform to ground irregularities and settle without fracturing.

- Coastal Protection: In marine environments, gabions serve as robust sea walls, groynes, and breakwaters, dissipating wave energy and protecting shorelines from tidal erosion and storm surges. The PVC-coated variants offer superior resistance to corrosive saltwater conditions.

- Erosion Control for Infrastructure: Used extensively around bridge abutments, culverts, and drainage structures to prevent localized scour and maintain structural integrity. Their adaptability makes them suitable for diverse hydrological conditions.

- Mining and Quarry Remediation: Gabions are used for stabilizing tailing dams, protecting critical infrastructure, and rehabilitating disturbed landscapes in mining areas, contributing to environmental recovery efforts.

- Architectural and Landscaping Features: Beyond their engineering utility, gabions are increasingly employed in modern landscape architecture for aesthetic retaining walls, sound barriers, and decorative elements due to their natural appearance when filled with local stone.

Figure 3: A Double Twisted Hexagonal Gabion Mesh Roll deployed in a riverbank protection project.

These application scenarios underscore the material's critical role in both safeguarding existing infrastructure and enabling the development of new, resilient construction projects across various environmental and geological conditions.

Technical Advantages and Performance Benefits

The inherent design and material properties of the Double Twisted Hexagonal Gabion Mesh Roll offer a compelling suite of technical advantages that differentiate it from other geotechnical solutions. These benefits translate directly into long-term cost savings, enhanced project reliability, and superior environmental outcomes for B2B clients.

Key Advantages:

- Superior Flexibility and Adaptability: The double-twisted hexagonal weave provides inherent flexibility, allowing the gabion structure to deform without losing integrity when subjected to ground settlement, seismic movements, or frost heave. This adaptability prevents catastrophic failure, a common issue with rigid structures.

- Excellent Permeability and Drainage: Gabion structures are naturally permeable, allowing water to pass through freely. This prevents hydrostatic pressure buildup behind retaining walls, which is a primary cause of failure in solid structures. Natural drainage also fosters vegetation growth, further enhancing stability and environmental integration.

- High Corrosion Resistance: Our wires are heavily hot-dip galvanized, meeting or exceeding industry standards for zinc coating weight. For aggressive environments, an additional UV-stabilized PVC coating provides a formidable barrier against chemical degradation, saltwater corrosion, and abrasion, extending the service life significantly.

- Ecological Compatibility: When filled with local stone, gabion structures blend seamlessly with the natural landscape. Their permeable nature supports soil infilling and vegetative growth over time, transforming them into living structures that enhance biodiversity and ecological function. This makes them ideal for environmentally sensitive projects.

- Ease and Speed of Installation: Supplied in rolls, the mesh is easy to transport and deploy. On-site assembly involves forming the baskets and filling them with readily available stone, reducing the need for specialized equipment and skilled labor. This leads to faster project completion times and reduced labor costs.

- Cost-Effectiveness: The long service life, minimal maintenance requirements, and use of local infill materials contribute to significant lifecycle cost savings compared to traditional concrete or masonry structures. The rapid installation further reduces overall project expenditure.

Figure 4: The durable coating on a Double Twisted Hexagonal Gabion Mesh Roll ensures longevity in harsh conditions.

These advantages underscore why the Double Twisted Hexagonal Gabion Mesh Roll remains a preferred choice for engineers and project managers seeking resilient, sustainable, and economically viable solutions in modern infrastructure development.

Vendor Comparison: Choosing the Right Supplier

Selecting a supplier for Double Twisted Hexagonal Gabion Mesh Roll is a critical decision that impacts project success, budget, and long-term performance. While numerous manufacturers exist, key differentiators in product quality, technical support, certification, and customization capabilities set leading vendors apart. Our company prides itself on a commitment to excellence, evidenced by our comprehensive certifications and decades of experience.

Key Differentiators in Gabion Mesh Suppliers:

| Feature/Criterion | Our Offering | Typical Competitor |

|---|---|---|

| Wire Material & Coating Quality | High-grade low-carbon steel (SAE 1006 equiv.), heavy hot-dip galvanization (≥245 g/m²), optional 0.5mm+ UV-stabilized PVC coating. Meets ASTM A975, EN 10244-2 standards. | Standard galvanized wire (often |

| Manufacturing Precision | Advanced double-twisting machinery ensures consistent mesh size, tight twists, and anti-unraveling properties. Precise selvage wire integration. ISO 9001 certified. | Variable mesh consistency, looser twists, potential for unraveling, inconsistent selvage wire. |

| Technical Support & Design | Dedicated engineering team for project consultation, design optimization, and specification guidance. Post-installation support. | Basic product information, limited or no project-specific engineering support. |

| Certifications & Compliance | ISO 9001:2015, CE certified, products meet ASTM, EN, and local regulations. Third-party test reports available. | May have basic certifications, or claim compliance without verifiable test data. |

| Customization Capability | Flexible manufacturing for specific wire diameters, mesh sizes, roll dimensions, and coating types to meet unique project demands. | Limited customization, primarily offering standard off-the-shelf products. |

| Lead Time & Logistics | Efficient production schedule, robust supply chain, and global logistics network ensure timely delivery, even for large orders. (Typical lead time: 2-4 weeks). | Longer lead times, potential for delays, limited shipping options. |

Our commitment to quality, backed by over two decades of experience and a strong portfolio of partnerships with leading civil engineering and environmental firms, positions us as an authoritative and trustworthy partner for your infrastructure projects. We ensure that every Double Twisted Hexagonal Gabion Mesh Roll delivered not only meets but often exceeds the most rigorous industry standards.

Customized Solutions

Recognizing that every B2B project presents unique challenges and specifications, we offer comprehensive customized solutions for our Double Twisted Hexagonal Gabion Mesh Roll products. Our engineering team collaborates closely with clients to tailor gabion mesh specifications to the exact requirements of their projects, ensuring optimal performance and cost-efficiency.

Customization Options Include:

- Wire Diameter: Available in a range from 2.0 mm to 4.0 mm for mesh wire, with corresponding selvage wire adjustments, to meet specific strength and durability requirements.

- Mesh Opening Size: Custom mesh openings (e.g., 60x80 mm, 80x100 mm, 100x120 mm, 120x150 mm) can be produced to accommodate different infill stone sizes and hydraulic conditions.

- Coating Type and Thickness: Clients can specify heavy hot-dip galvanization levels or opt for additional PVC coating with customized thickness for superior corrosion and abrasion resistance in extremely aggressive environments. Options for Galfan (Zn-Al alloy) coating are also available for enhanced protection.

- Roll Dimensions: Production of custom roll lengths and widths to minimize waste and optimize logistics for large-scale projects.

- Geotextile Integration: Recommendations and supply of compatible geotextile fabrics for specific applications requiring filtration, separation, or reinforcement in conjunction with gabion structures.

Our proactive approach to customization ensures that you receive a solution perfectly aligned with your project's unique environmental, structural, and budgetary constraints, delivering maximum value and performance.

Application Case Studies

The efficacy and reliability of our Double Twisted Hexagonal Gabion Mesh Roll are best demonstrated through its successful deployment in challenging real-world projects. These case studies highlight the practical advantages and long-term performance benefits our products deliver to diverse clientele.

Case Study 1: Riverbank Stabilization in a Major Agricultural Region

Challenge: A critical section of a river in a flood-prone agricultural region experienced severe erosion, threatening arable land and local infrastructure. Traditional concrete solutions were deemed too costly and environmentally intrusive.

Solution: Approximately 15,000 square meters of heavily galvanized Double Twisted Hexagonal Gabion Mesh Roll (80x100mm mesh, 2.7mm wire diameter) were utilized to construct a series of tiered gabion retaining walls and revetments. The gabions were filled with locally sourced river stones, ensuring excellent permeability and rapid drainage.

Outcome: The project, completed within 4 months, successfully stabilized the riverbanks. Post-installation monitoring over five years has shown no signs of erosion or structural failure. The gabions have gradually integrated with the environment, supporting vegetation growth and enhancing the ecological value of the river corridor, demonstrating exceptional long-term erosion control and environmental compatibility.

Case Study 2: Slope Reinforcement for a Mountain Highway

Challenge: A new section of a mountain highway required stabilization of a particularly steep and geologically unstable cut slope, prone to rockfalls and shallow landslides. The project demanded a flexible yet robust solution to handle potential ground movements.

Solution: A combination of PVC-coated Double Twisted Hexagonal Gabion Mesh Roll (100x120mm mesh, 3.0mm core wire with 0.5mm PVC coating) was employed to construct a series of gabion buttresses and face stabilization elements. The PVC coating was chosen for its enhanced durability and corrosion resistance in the alpine environment, which experiences significant freeze-thaw cycles and potentially acidic rainfall.

Outcome: The gabion system provided the necessary structural support and flexibility, effectively mitigating the risk of slope failure. Its inherent permeability prevented hydrostatic pressure buildup, and the robustness of the double-twisted mesh successfully contained minor rockfalls, ensuring highway safety. The project has been operational for over 10 years without requiring significant maintenance, underscoring the product's resilience and longevity in challenging terrain.

Figure 5: Gabion structures created from Double Twisted Hexagonal Gabion Mesh Roll providing robust slope stabilization.

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of a double-twisted hexagonal mesh over single-twisted or welded mesh?

A1: The double-twisted hexagonal weave provides superior structural integrity and anti-unraveling properties. If one wire breaks, the adjacent twists prevent the entire mesh from unraveling, ensuring continued performance and safety. It also offers greater flexibility and adaptability to ground movement compared to rigid welded mesh.

Q2: How does the PVC coating enhance the lifespan of the Double Twisted Hexagonal Gabion Mesh Roll?

A2: The PVC coating provides an additional layer of protection over the galvanized wire, significantly improving resistance to chemical attack, abrasion, and UV degradation. This is particularly crucial in highly corrosive environments like saltwater, acidic soils, or industrial areas, extending the service life of the gabions by decades.

Q3: Can these gabion mesh rolls be used in marine or coastal environments?

A3: Yes, absolutely. For marine or coastal applications, we highly recommend our PVC-coated Double Twisted Hexagonal Gabion Mesh Roll. The PVC layer offers excellent resistance to saltwater corrosion, tidal forces, and abrasion from sand and debris, making it ideal for sea walls, groynes, and breakwaters.

Q4: What kind of infill material is recommended for gabions?

A4: Gabions are typically filled with durable, non-frost-susceptible, angular or rounded stones (rock, gravel, cobbles) that are readily available locally. The stone size should be larger than the mesh opening to prevent egress. Using local materials reduces transportation costs and carbon footprint.

Q5: What certifications do your gabion mesh products hold?

A5: Our manufacturing processes are ISO 9001:2015 certified, and our products comply with international standards such as ASTM A975-97 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) and EN 10223-3 (Steel wire and wire products for fencing and netting—Hexagonal steel wire mesh for civil engineering purposes). We also hold CE certification for European markets.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment

Our standard lead time for the production and dispatch of Double Twisted Hexagonal Gabion Mesh Roll is typically 2-4 weeks, depending on the order volume, specific customization requirements, and current production schedules. For urgent projects, expedited manufacturing and logistics options can be arranged. We maintain a robust supply chain and efficient production lines to ensure timely fulfillment and minimize project delays. Clients are provided with detailed production and shipping updates throughout the order process.

Warranty Commitments

We stand by the superior quality and durability of our products. Our Double Twisted Hexagonal Gabion Mesh Roll comes with a comprehensive material and workmanship warranty. Heavily galvanized products are typically warranted for 10 years against manufacturing defects and premature corrosion in non-aggressive environments. PVC-coated products carry an extended warranty of 25 years under normal operating conditions, reflecting their enhanced resistance to environmental degradation. Specific warranty terms and conditions are provided with each quotation.

Customer Support and After-Sales Service

Our commitment to our B2B partners extends beyond product delivery. We offer dedicated technical support from our team of experienced engineers and customer service professionals. This includes pre-sales consultation, assistance with product selection and specification, design optimization, and post-installation advice. For any inquiries or support needs, our team is accessible via phone, email, and a dedicated online portal. We pride ourselves on responsive and effective after-sales support to ensure the long-term success of your projects.

Contact us today to discuss your project requirements and discover how our expertise and high-quality Double Twisted Hexagonal Gabion Mesh Roll can contribute to your success.

References

- ASTM A975-97. (2020). Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating). ASTM International.

- EN 10223-3:2013. (2013). Steel wire and wire products for fencing and netting - Hexagonal steel wire mesh for civil engineering purposes. European Committee for Standardization.

- Maccaferri. (2009). Gabion and Reno Mattress Design and Construction Manual.

- Koerner, R. M. (2012). Designing with Geosynthetics (6th ed.). Pearson Prentice Hall.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025