Aug . 28, 2025 00:20 Back to list

Strong Double Twisted Hexagonal Gabion Mesh Roll | Erosion Control

Introduction to Double Twisted Hexagonal Gabion Mesh Rolls

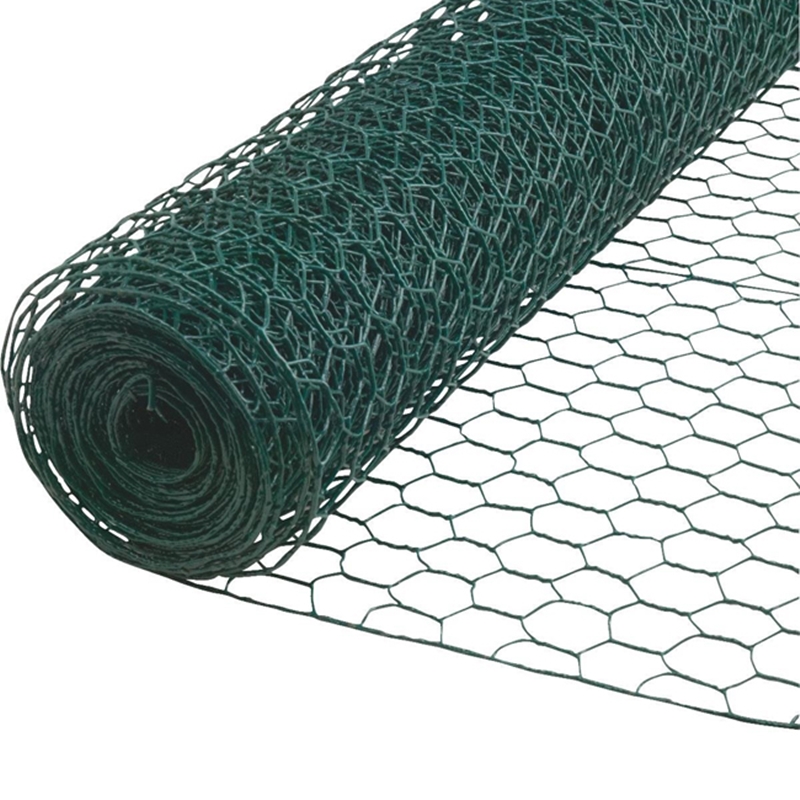

In the realm of civil engineering, environmental protection, and infrastructure development, robust and adaptable solutions for erosion control, soil stabilization, and hydraulic structures are paramount. Among the most reliable and extensively utilized materials is the Double Twisted Hexagonal Gabion Mesh Roll. This product, characterized by its unique double-twist weave, offers superior strength, flexibility, and durability, making it an indispensable component in a wide array of demanding applications. Its innovative design ensures that even if one wire breaks, the integrity of the mesh is maintained, providing exceptional structural stability and longevity. Manufactured from high-quality steel wire, typically galvanized or PVC-coated for enhanced corrosion resistance, these gabion mesh rolls are designed to withstand harsh environmental conditions and significant hydrological forces, delivering a sustainable and aesthetically pleasing solution for modern engineering challenges.

The inherent permeability of gabion structures, formed using these mesh rolls, allows for natural drainage, reducing hydrostatic pressure behind retaining walls and promoting vegetative growth within the structure, which further enhances stability and ecological integration. This characteristic makes them a preferred choice over rigid, impermeable structures in many scenarios where environmental impact and long-term sustainability are key considerations.

Industry Trends and Market Dynamics

The global market for gabion solutions is experiencing steady growth, driven by several macro-economic and environmental factors. Increased governmental investment in infrastructure projects, particularly in developing nations, coupled with a heightened focus on climate change adaptation and disaster mitigation, are key accelerators. The rising frequency and intensity of extreme weather events, such as heavy rainfall leading to increased erosion and landslides, have amplified the demand for resilient and effective ground stabilization and hydraulic control systems.

Technological advancements in wire manufacturing, coating technologies (e.g., Galfan, high-performance polymers), and mesh weaving machinery have further improved the performance and cost-effectiveness of Double Twisted Hexagonal Gabion Mesh Roll products. There's a growing preference for eco-friendly and sustainable construction materials, where gabions excel due to their use of natural fill materials and their ability to integrate with the environment over time. The "green infrastructure" movement actively promotes solutions that enhance biodiversity and ecological functions, a perfect fit for gabion applications. Furthermore, the trend towards faster, more efficient construction methods benefits gabions, as they can be rapidly deployed and filled on-site, reducing labor and equipment costs.

Urbanization and industrial expansion continue to encroach upon natural landscapes, necessitating robust solutions for retaining walls, noise barriers, and architectural landscaping that are both functional and visually appealing. The versatility and aesthetic potential of gabion structures position them favorably within these evolving market demands.

Detailed Manufacturing Process Flow

The production of a Double Twisted Hexagonal Gabion Mesh Roll involves a sophisticated, multi-stage process designed to ensure product integrity, durability, and compliance with international standards such as ISO 9001 for quality management and ASTM A975-97 for wire mesh fabric.

Manufacturing Process Steps

1. Wire Rod Sourcing & Drawing

High-carbon steel wire rods are sourced from reputable mills, ensuring compliance with tensile strength and elongation specifications. These rods undergo a cold drawing process to achieve the precise wire diameter required for gabion mesh production.

2. Surface Treatment (Galvanization)

The drawn wires are then hot-dip galvanized or coated with a Galfan (Zn-5%Al-MM) alloy. This metallurgical bonding process creates a robust, sacrificial coating, significantly enhancing corrosion resistance and extending the product's service life, often exceeding 50 years in benign environments.

3. PVC Coating (Optional)

For highly corrosive environments, such as marine or polluted industrial areas, a supplementary PVC coating is applied over the galvanized wire. This extra layer provides superior protection against chemical degradation, abrasion, and UV radiation, ensuring prolonged durability.

4. Weaving Process

Specialized double-twist weaving machines intertwine adjacent wires in a hexagonal pattern, creating robust and flexible mesh fabric. The double-twist ensures that wire breaks are localized, preventing unraveling and maintaining the mesh's structural integrity.

5. Cutting, Edging & Coiling

The continuous mesh fabric is cut to specified dimensions. Edges are reinforced with heavier selvedge wires, which are mechanically crimped onto the mesh to provide additional strength and prevent unraveling. The finished mesh is then coiled into compact rolls for efficient transport and storage.

6. Quality Control & Testing

Throughout the process, stringent quality control measures are implemented. This includes testing wire tensile strength, elongation, coating thickness (zinc/PVC), mesh opening size, and selvedge wire attachment. Compliance with international standards such as ISO, ASTM, and EN is meticulously verified.

Target Industries and Advantages: These robust mesh rolls are extensively used across various sectors including water supply & drainage, petrochemical, metallurgy, mining, and civil engineering. Their energy-saving advantage comes from their passive yet effective erosion control capabilities, reducing the need for continuous active maintenance. The superior corrosion resistance, particularly with PVC-coated options, offers a significant advantage in areas exposed to aggressive chemicals or saline environments, extending the service life of critical infrastructure components.

Technical Specifications and Performance Parameters

Understanding the technical specifications of a Double Twisted Hexagonal Gabion Mesh Roll is crucial for engineers and procurement specialists to ensure optimal performance and compliance with project requirements. The following table outlines typical parameters that define the quality and suitability of these products for various applications.

These specifications collectively determine the load-bearing capacity, resistance to deformation, and long-term performance in dynamic environments. The selection of appropriate wire diameter, mesh opening, and coating type must align directly with the specific geotechnical and environmental conditions of the project. For instance, in areas prone to seismic activity or differential settlement, the high elongation properties of double-twisted wire are critical for structural resilience.

Application Scenarios and Strategic Advantages

The versatility of Double Twisted Hexagonal Gabion Mesh Roll allows for its deployment across a multitude of engineering and environmental applications. Its inherent design characteristics provide strategic advantages over conventional construction methods.

-

Erosion Control and Soil Stabilization:

Gabion mattresses (Reno mattresses) formed from these rolls are widely used for channel lining, riverbank protection, and slope stabilization. Their flexibility allows them to conform to ground movement without losing integrity, making them ideal for dynamic environments. The permeable nature prevents hydrostatic pressure buildup, a common cause of failure in rigid structures.

-

Retaining Walls and Abutments:

Gabion retaining walls are gravity structures known for their robustness and ability to withstand significant lateral earth pressures. They are particularly advantageous in areas with poor soil conditions or differential settlement, offering superior resilience compared to rigid concrete walls. The aesthetic appeal of natural stone fill also integrates well with landscapes.

-

Rockfall Protection:

For slopes susceptible to rockfall, gabion mesh rolls can be deployed as drapery systems or used to construct rockfall barriers. The double-twist design provides high tensile strength and puncture resistance, effectively containing falling debris and ensuring safety for infrastructure and personnel below.

-

Weir Structures and Dam Overflows:

In hydraulic engineering, gabions are used to construct low-level weirs, check dams, and spillways. Their inherent permeability dissipates energy from flowing water, reducing scour and erosion downstream, while their mass provides stability against hydraulic forces.

-

Architectural and Landscaping Features:

Beyond their primary engineering functions, gabion structures are increasingly being used for aesthetic purposes in urban and commercial landscaping, creating visually appealing facades, planter boxes, noise barriers, and decorative elements that blend seamlessly with natural environments.

Core Technical Advantages

The intrinsic design and material properties of Double Twisted Hexagonal Gabion Mesh Roll confer a distinct set of technical advantages that contribute to their widespread adoption in critical infrastructure projects:

-

✔ Superior Flexibility and Adaptability:

Unlike rigid structures, gabions can tolerate significant differential settlement without fracturing or compromising structural integrity. This makes them ideal for soft ground conditions, seismic zones, or areas with unpredictable subsurface movements. The double-twist weave allows for localized deformation while maintaining overall mesh cohesion.

-

✔ Exceptional Permeability and Drainage:

The open structure of gabion units allows free passage of water, effectively dissipating hydraulic pressures. This eliminates the need for complex and costly drainage systems behind retaining structures and mitigates uplift forces in river training works, thereby increasing the stability and reducing the risk of failure.

-

✔ High Corrosion Resistance and Longevity:

Utilizing heavily galvanized or Galfan-coated wire, often supplemented with a robust PVC coating, ensures outstanding resistance to rust, abrasion, and chemical attack. This multi-layer protection significantly extends the service life, even in aggressive environments, reducing lifecycle costs and maintenance requirements.

-

✔ Environmental Compatibility and Aesthetic Integration:

Gabion structures are inherently eco-friendly, using locally available stone fill and promoting natural vegetation growth over time. This greening effect enhances biodiversity, improves landscape aesthetics, and helps create self-sustaining ecological systems, aligning with modern environmental regulations and public expectations.

-

✔ Cost-Effectiveness and Ease of Installation:

Gabions typically require minimal foundation preparation and can be filled with readily available local rock, significantly reducing material and transportation costs. Their simple assembly process allows for rapid construction, often by unskilled labor, leading to substantial savings in overall project expenditure and timelines.

Vendor Comparison: Selecting the Right Partner

Choosing the right supplier for Double Twisted Hexagonal Gabion Mesh Roll is a critical decision that impacts project timelines, budget, and long-term structural performance. A thorough vendor comparison should extend beyond just price, focusing on material quality, manufacturing capabilities, adherence to standards, and comprehensive customer support.

Investing in a reputable supplier like XZ Metal, with a proven track record and adherence to stringent international standards, ensures not only product quality but also provides the peace of mind that comes with robust technical support and reliable service. Our long-standing partnerships with major engineering firms and public works departments underscore our commitment to excellence.

Customized Solutions for Complex Projects

Many large-scale infrastructure projects or those situated in unique geographical conditions often require more than off-the-shelf products. Recognizing this, leading manufacturers offer extensive customization capabilities for their Double Twisted Hexagonal Gabion Mesh Roll products. This bespoke approach ensures that the gabion solution is precisely tailored to meet the specific demands and constraints of each project.

-

Tailored Dimensions:

While standard roll widths and lengths are available, manufacturers can produce custom sizes to minimize waste and optimize construction efficiency for specific site conditions, reducing on-site cutting and labor.

-

Specialized Wire Diameters and Mesh Openings:

Projects requiring enhanced structural strength or fine particle retention may necessitate adjustments to wire gauge or mesh aperture. Custom options ensure the optimal balance between cost-effectiveness and engineering requirements.

-

Advanced Coating Systems:

Beyond standard galvanization or Galfan, specific projects in extreme environments (e.g., highly acidic soils, saltwater immersion) may benefit from customized PVC compounds or multi-layer coating systems formulated for superior chemical and abrasion resistance.

-

Integrated Design Support:

Providers often offer comprehensive design and engineering support, collaborating with clients to develop project-specific gabion solutions, including detailed drawings, structural calculations, and installation guidance, ensuring optimal performance and compliance with local regulations.

Application Case Studies: Proven Performance

The effectiveness and reliability of Double Twisted Hexagonal Gabion Mesh Roll are best demonstrated through real-world applications. Here are a few representative case studies showcasing their successful deployment:

Case Study 1: Riverbank Protection in a High-Flow River System

Client: Regional Water Management Authority

Location: Southeast Asia, along a major river prone to seasonal flooding.

Challenge: Severe erosion of riverbanks due to high velocity flows during monsoon seasons, threatening adjacent agricultural land and a vital transportation bridge.

Solution: Extensive use of PVC-coated 80x100mm mesh, 2.7mm wire diameter Double Twisted Hexagonal Gabion Mesh Roll to construct Reno mattresses and gabion retaining walls along a 3 km stretch of the riverbank. The gabions were filled with locally sourced river stone.

Outcome: Over five years, the gabion structures have successfully withstood multiple severe flood events, demonstrating excellent stability and minimal signs of erosion. The permeable nature of the gabions allowed for successful re-vegetation within the voids, further stabilizing the banks and enhancing ecological value. The client reported a significant reduction in maintenance costs compared to previous rigid concrete solutions.

Case Study 2: Landslide Mitigation for a Mountain Highway

Client: National Highway Department

Location: Mountainous region, prone to rockfalls and shallow landslides.

Challenge: A critical section of a newly constructed highway was vulnerable to frequent rockfalls and slope failures, posing significant safety risks and causing road closures.

Solution: Installation of multi-tiered gabion retaining walls and rockfall drapery systems using 100x120mm mesh, 3.0mm Galfan-coated Double Twisted Hexagonal Gabion Mesh Roll. The retaining walls provided structural support to the toe of the slope, while the drapery system draped over unstable rock faces to contain loose material.

Outcome: Since installation, no major rockfall incidents have been reported in the protected sections. The flexibility of the gabion structures adapted well to minor ground movements, and the high-strength Galfan coating ensured long-term durability in the exposed mountain environment. The solution proved to be significantly more cost-effective and faster to implement than traditional shotcrete or concrete retaining structures.

Trustworthiness and Customer Assurance (FAQ, Lead Time, Warranty, Support)

At XZ Metal, our commitment to customer trust is paramount. We provide comprehensive information and robust support for every Double Twisted Hexagonal Gabion Mesh Roll product.

Frequently Asked Questions (FAQ)

Q: What is the typical service life of your gabion mesh rolls?

A: Our heavily galvanized gabion mesh rolls typically have a design life of 25-50 years, depending on the environment. For highly corrosive conditions, our PVC-coated options can extend this to 75-100 years, backed by independent testing.

Q: Are your products certified to international standards?

A: Yes, all our gabion mesh rolls are manufactured in compliance with strict international standards, including ASTM A975-97, EN 10223-3, and ISO 9001:2015 for quality management. Test certificates and material data sheets are available upon request.

Q: Can I get technical assistance for project design?

A: Absolutely. Our experienced engineering team offers comprehensive technical support, including design recommendations, material selection guidance, and project-specific calculations to ensure optimal performance of our gabion solutions.

Q: What type of infill material is recommended for gabions?

A: We recommend hard, durable, non-frost susceptible rock, typically ranging from 75mm to 150mm in diameter, depending on the mesh opening and application. Local stone sources are often preferred for cost and environmental benefits.

Lead Time and Fulfillment

We maintain efficient production schedules to meet diverse project demands. Standard orders for Double Twisted Hexagonal Gabion Mesh Roll typically have a lead time of 2-4 weeks, depending on quantity and specific customization requirements. Expedited production and delivery options are available for urgent projects. Our logistics team works with a network of reliable freight partners to ensure timely and secure global delivery. We provide transparent tracking and regular updates throughout the shipping process.

Warranty Commitments

XZ Metal stands behind the quality of its products. We offer a comprehensive warranty for our Double Twisted Hexagonal Gabion Mesh Roll. This includes:

- 5-Year Manufacturing Defect Warranty: Covers any flaws in material or workmanship.

- 20-Year Anti-Corrosion Warranty (Galvanized/Galfan): Guarantees the performance of our coating systems under normal environmental conditions.

- Lifetime Warranty (PVC-Coated): For products exposed to highly aggressive environments, providing exceptional long-term protection against degradation.

Specific terms and conditions apply and are provided with every order.

Customer Support and After-Sales Service

Our commitment extends beyond product delivery. XZ Metal offers dedicated customer support available via phone, email, and online portal. Our team is equipped to assist with:

- Installation guidance and best practices.

- Troubleshooting and technical queries.

- Post-installation inspection and maintenance advice.

- Processing of warranty claims and replacement parts.

We strive to build lasting relationships with our clients by providing prompt, knowledgeable, and reliable support throughout the entire project lifecycle.

References

- A. J. B. Gabions and Reinforced Earth Structures. Geo-Engineering & Geo-Environmental Engineering, University of Nottingham.

- Maccaferri. Technical Manual: Gabion Structures. Maccaferri Global.

- ASTM A975/A975M-11(2017), Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With Poly(Vinyl Chloride) (PVC) Coating). ASTM International.

- EN 10223-3:2013, Steel wire and wire products for fencing and netting - Hexagonal steel wire mesh for civil engineering purposes. European Committee for Standardization.

- FHWA Publication No. FHWA-CFL/TD-02-001, Design and Construction of Gabion Walls. U.S. Department of Transportation, Federal Highway Administration.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025