Oct . 06, 2025 00:50 Back to list

Anti-Rust? Hot Dipped Galvanized Steel Grating/Bar Grating

Hot Dipped Galvanized Steel Grating/Bar Grating is a key solution in the manufacturing industry, specifically within Fabricated metal products and Metal structure manufacturing. This article explores how Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hot Dipped Galvanized Steel Grating/Bar Grating Overview

- Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Hot Dipped Galvanized Steel Grating/Bar Grating Overview

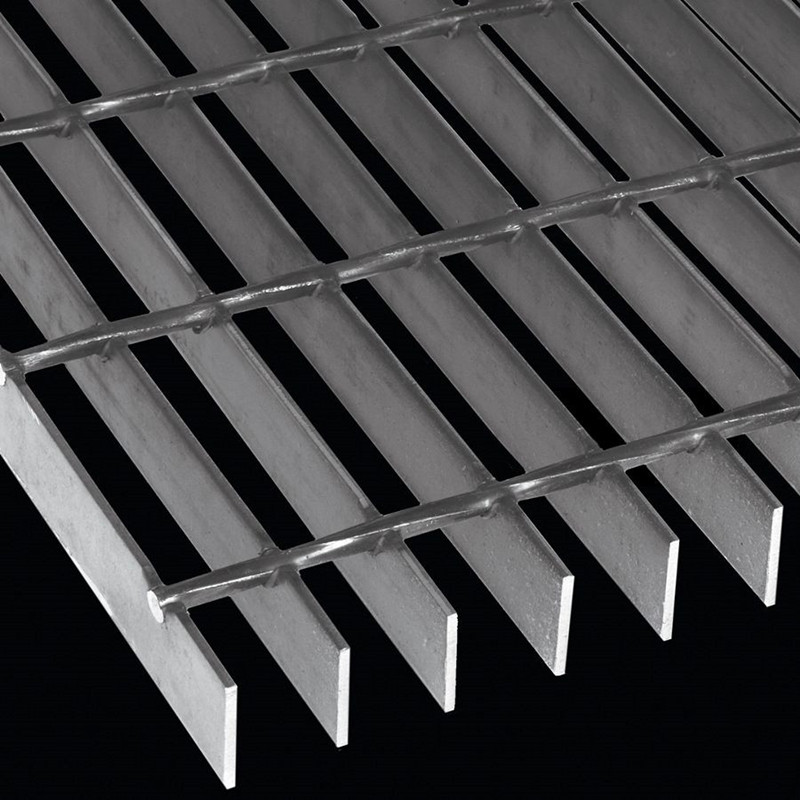

Hot Dipped Galvanized Steel Grating/Bar Grating is a load-bearing flooring and decking solution formed by welding or press-locking bearing bars to cross bars, then immersing the finished panels in molten zinc for long-term corrosion protection. For B2B decision makers in fabricated metal products and metal structure manufacturing, this product offers a dependable combination of structural strength, slip resistance, drainage, and ventilation—ideal for platforms, walkways, mezzanines, and trench covers.

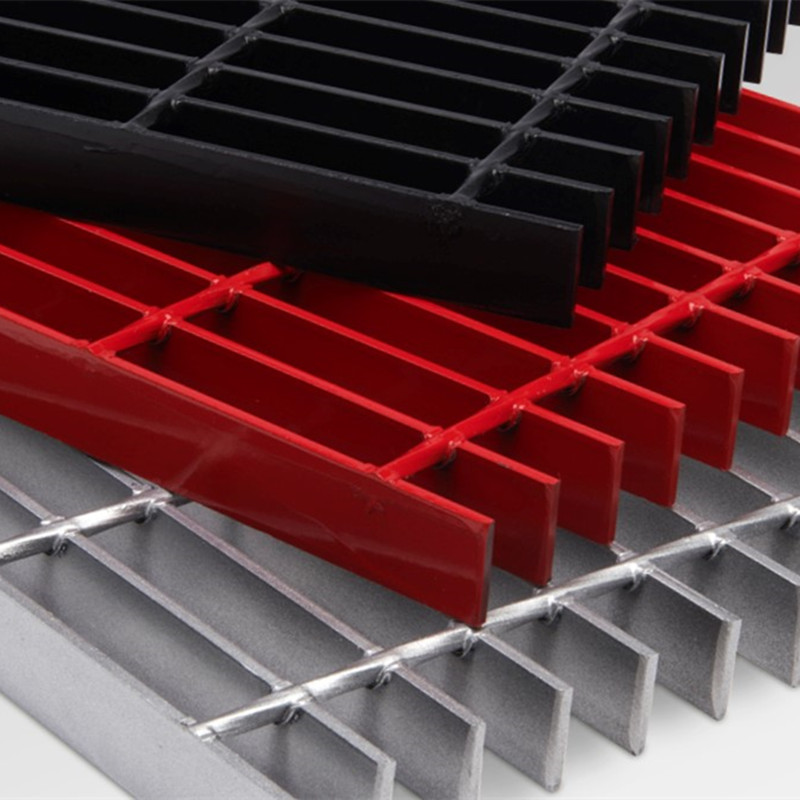

Typical options include plain or serrated bearing bars in common sizes (e.g., 25×3 mm to 50×5 mm), bearing bar spacing of 30–40 mm, and cross bar spacing around 50–100 mm. The hot-dip galvanizing process generally follows widely adopted standards such as ASTM A123 or EN ISO 1461, delivering robust zinc layers that provide decades of service in outdoor or harsh environments. Panel sizes and edge banding can be customized to project drawings to streamline installation and minimize onsite cutting.

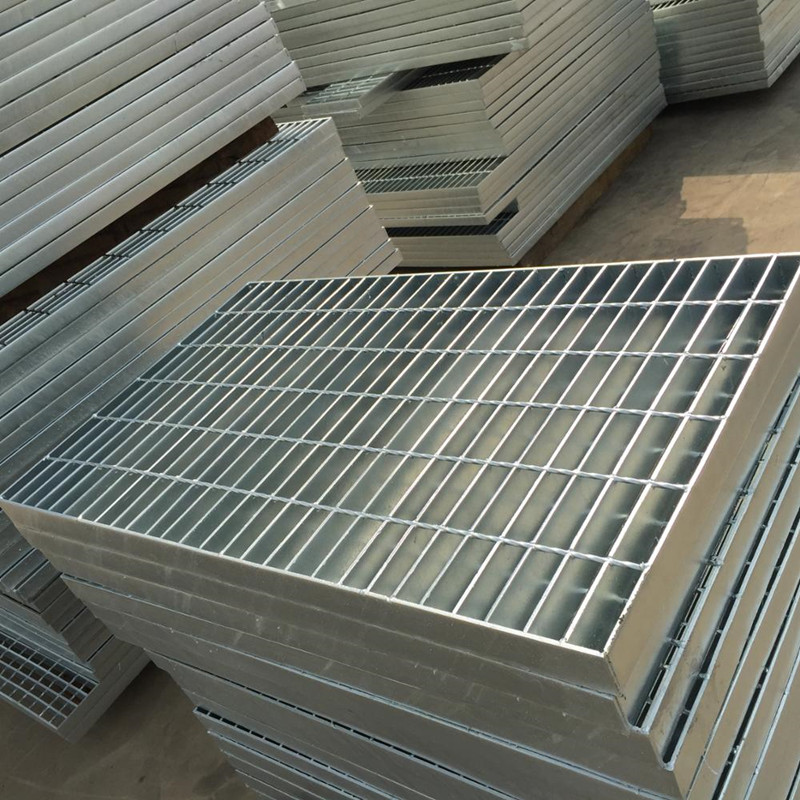

Anping County Xingzhi Metal Wiremesh Products Co.,Ltd manufactures Hot Dipped Galvanized Steel Grating/Bar Grating with tight dimensional control and practical customization. From small replacement panels to large platform packages, the company supports engineering teams with accurate takeoffs, fabrication-ready drawings, and prompt lead times—helping projects stay on schedule and within budget.

Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

In metal structure manufacturing, Hot Dipped Galvanized Steel Grating/Bar Grating integrates seamlessly into steel frames, modular skids, pipe racks, maintenance platforms, and access stairs. Its open-grid design offers superior drainage and ventilation, which prevents pooling liquids, reduces slip hazards, and supports process airflow. Serrated bearing bars further increase traction on catwalks, stair treads, and loading docks, making it a go-to choice for safety-focused facilities.

Key advantages include high load capacity at relatively low weight compared to solid plate; long-lasting corrosion protection from hot-dip galvanizing; easy field handling and fastening; and simplified maintenance. For fabrication shops and EPC contractors, standardized panel sizes, toe plates, end banding, and custom cutouts accelerate shop assembly and site installation, reducing labor and crane time.

Anping County Xingzhi Metal Wiremesh Products Co.,Ltd brings deep category expertise—supporting OEMs and fabricators with value engineering, nesting optimization, and consistent quality across batches. Whether you need heavy-duty grating for industrial platforms, ADA-conscious options for public infrastructure, or stair treads with checkered nosing, the company delivers tailored, code-aware solutions that align with your project specifications and safety targets.

Cost, Maintenance & User Experience

Total cost of ownership for Hot Dipped Galvanized Steel Grating/Bar Grating is typically favorable versus painted alternatives. The hot-dip zinc coating protects edges, welds, and hard-to-reach areas, minimizing touch-up work and repainting cycles. Over a 15–25 year horizon, many facilities realize lower lifecycle costs through fewer shutdowns for recoating, reduced consumables, and less frequent panel replacement—particularly in outdoor or corrosive settings.

Maintenance is straightforward: periodic inspection for mechanical damage, routine washing to remove debris and corrosive contaminants, and timely replacement of damaged panels. Fast mechanical fastening means sections can be removed for equipment access and reinstalled without specialized tools. Customers in the fabricated metal products sector often report shorter installation times, improved safety performance on wet surfaces, and predictable upkeep budgets versus checker plate or painted grating.

Anping County Xingzhi Metal Wiremesh Products Co.,Ltd enhances ROI with accurate pre-cut panels, consistent galvanizing quality, and reliable packaging that reduces transit damage. The result is fewer site surprises, faster commissioning, and long service life—key outcomes for procurement and operations leaders focused on capex efficiency and uptime.

Sustainability & Market Trends in manufacturing

Sustainability priorities in manufacturing increasingly emphasize durability, material efficiency, and reduced maintenance emissions. Hot Dipped Galvanized Steel Grating/Bar Grating supports these goals by offering long service life, limited need for recoating, and recyclability at end of life. The hot-dip galvanizing process creates a metallurgical bond that protects steel in demanding conditions, often avoiding recurring VOC emissions associated with frequent repainting.

From infrastructure upgrades to plant modernization, market demand continues to favor safe, compliant access systems that integrate with digital project workflows. Buyers expect traceability, consistent specifications, and documentation to help meet internal ESG reporting. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd positions itself as a forward-thinking supplier by offering drawing support, material documentation upon request, and production practices that minimize waste through optimized cutting and bundling.

As regulations and owner standards evolve, selecting a partner that understands load criteria, slip-resistance needs, and galvanizing best practices reduces project risk. With proven manufacturing capabilities and a focus on quality and responsiveness, Anping County Xingzhi Metal Wiremesh Products Co.,Ltd helps B2B teams align technical performance with sustainability and procurement objectives.

Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Hot Dipped Galvanized Steel Grating/Bar Grating delivers dependable strength, corrosion resistance, and safety for platforms, walkways, and structural access across the manufacturing, fabricated metal products, and metal structure sectors. Backed by responsive engineering support and consistent quality, Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is a trusted partner for projects that demand durability and predictable lifecycle costs.

Contact us: email: sales2@xzmetal.com

Visit our website: https://www.xzmetal.com

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025