Дек . 15, 2024 03:23 Back to list

custom expanded mesh

Understanding Custom Expanded Mesh An Essential Material for Diverse Applications

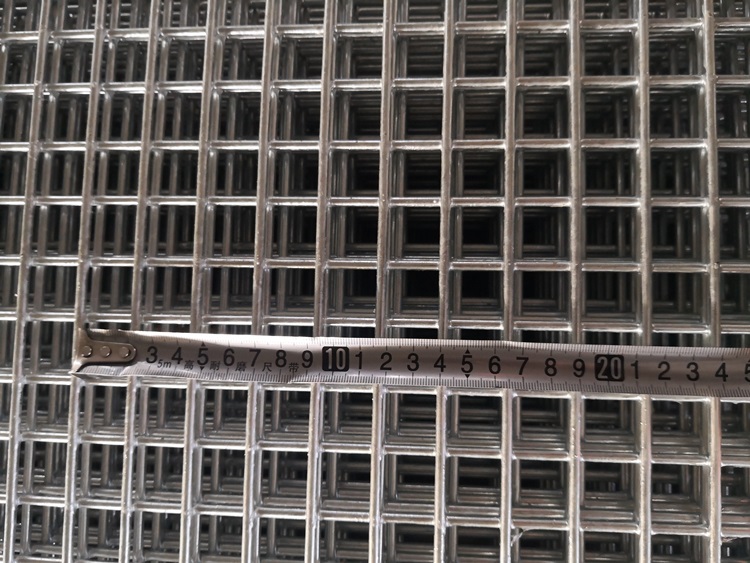

In the realm of industrial materials, custom expanded mesh stands out as an innovative solution catering to various needs across multiple sectors. Expanded mesh is a versatile material that is made by taking a flat sheet of metal—often aluminum, steel, or plastic—and cutting it in a specific pattern, allowing it to expand into a mesh-like structure. This unique manufacturing process not only enhances the strength of the material but also dramatically increases its surface area, making it an ideal choice for various applications.

One of the primary advantages of custom expanded mesh is its adaptability. Manufacturers can create mesh with specific hole shapes, sizes, and patterns tailored to particular requirements. This customizability allows businesses to utilize expanded mesh for applications ranging from architectural designs to industrial filtration systems. For instance, in building constructions, custom expanded mesh can serve decorative purposes while providing functional benefits, such as strength and security. Designers often choose specific patterns that match the aesthetic of a building, contributing both to its visual appeal and structural integrity.

In industrial contexts, custom expanded mesh plays a crucial role in filtration processes

. The mesh can be designed with different hole sizes to filter out various particulate sizes, ensuring that processes remain efficient and effective. For example, in food processing or pharmaceuticals, stringent cleanliness standards require filtration systems that can prevent contamination. Custom expanded mesh can meet these high standards by allowing only desired particles to pass through while trapping larger contaminants.Furthermore, the lightweight nature of expanded mesh makes it a favorable choice in applications where weight is a critical factor. This property is particularly beneficial in the aerospace and automotive industries, where reducing weight can enhance fuel efficiency and overall performance. Custom expanded mesh can be employed in manufacturing components that require both strength and minimal weight, thus contributing to the design of more efficient vehicles and aircraft.

custom expanded mesh

Additionally, custom expanded mesh is increasingly utilized in the realm of environmental sustainability. With the growing emphasis on eco-friendly materials and practices, manufacturers are exploring expanded mesh made from recycled materials. This not only contributes to reducing waste but also appeals to consumers who prioritize sustainability in their procurement decisions. The mesh’s inherent durability means it can withstand harsh environmental conditions, making it suitable for outdoor applications such as fencing, landscaping, and architectural façades.

Another vital aspect of custom expanded mesh is its ease of installation and maintenance. Compared to traditional materials, expanded mesh can be integrated into systems more easily, saving both time and labor costs during installation. Its maintenance is minimal, requiring only occasional cleaning to preserve its functionality and aesthetics. This factor is particularly advantageous in industries that operate under tight schedules and where downtime can result in significant financial losses.

Despite its many advantages, selecting the right type of custom expanded mesh for a specific application requires careful consideration of various factors, including material composition, hole size, and mesh thickness. Engaging with specialized manufacturers who understand the intricacies of expanded mesh can provide valuable insights into making the right choice. Additionally, exploring the latest advancements in manufacturing techniques can further enhance performance characteristics.

In conclusion, custom expanded mesh serves as a multifaceted material that meets the demands of diverse applications across industries. Its adaptability, strength, lightweight nature, sustainability potential, and ease of use make it a preferred choice among designers and engineers alike. As industries continue to evolve and prioritize both functionality and aesthetics, the demand for custom expanded mesh is likely to grow, paving the way for even more innovative uses in the future. Understanding its properties and applications will empower businesses to harness its full potential, leading to enhanced performance and creative solutions in various fields.

-

High Quality 9 Gauge Expanded Metal Mesh & Chain Link Wire Mesh Fence Manufacturer

NewsJun.10,2025

-

Barbed Wire Roll Price - Wholesale Exporters & Reliable Factories Supply

NewsJun.10,2025

-

High-Quality Temporary Mesh Fence Panels for Sale Durable Temporary Fence Panels Supplier

NewsJun.10,2025

-

Welded Wire Fence Mesh Exporters Custom Sizes & Competitive Pricing

NewsJun.10,2025

-

Durable China Expanded Metal Security Mesh High-Security & Affordable

NewsJun.10,2025

-

White Expanded Metal Mesh Durable for Temp Fencing & Plaster

NewsJun.10,2025