Dec . 10, 2024 23:45 Back to list

Top Manufacturers of High-Quality Bar Grating for Industrial Applications

Best I-Bar Grating Factories A Comprehensive Overview

When it comes to industrial applications requiring high strength-to-weight ratios and excellent load-bearing capabilities, I-bar grating stands out as an ideal solution. This unique form of grating, characterized by its I-shaped cross-section, is widely used in various sectors, ranging from construction to manufacturing. However, the effectiveness of I-bar grating is heavily dependent on the quality of the manufacturing process and the materials used. In this article, we will explore some of the best I-bar grating factories around the globe, highlighting their production methods, quality standards, and innovative approaches.

Understanding I-Bar Grating

I-bar grating is primarily made from steel, aluminum, or fiberglass, which are all recognized for their durability and strength. The bars are formed into an I-shape that provides better load distribution compared to traditional flat bars. This unique design not only enhances the structural integrity of the grating but also reduces the overall weight, making it easier to handle and install. Common applications include walkways, platforms, and drainage covers in industrial environments.

Criteria for Selecting the Best Factories

When evaluating I-bar grating manufacturers, several criteria should be considered

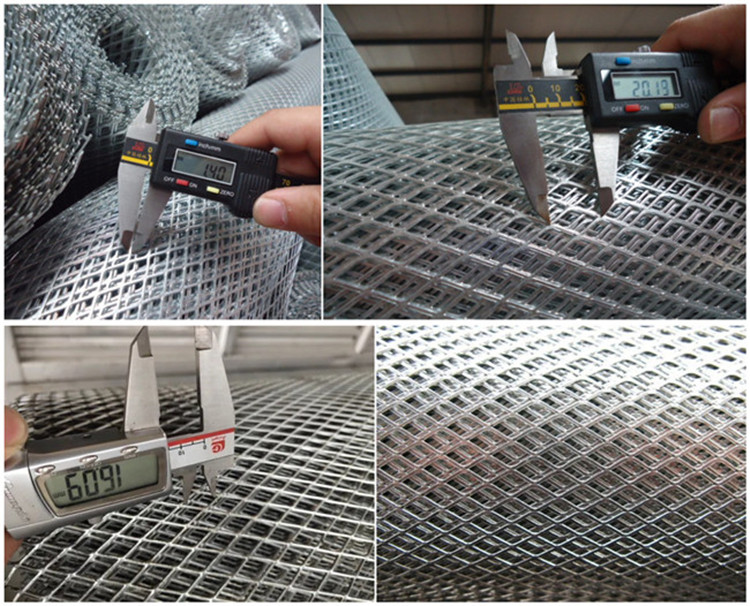

1. Quality Control The best factories adhere to strict quality control measures, ensuring that every product meets industry standards. This includes material inspections, dimensional checks, and performance testing.

2. Manufacturing Techniques Advanced manufacturing techniques, such as automated welding and precision machining, often result in better-quality grating products. Factories that invest in modern equipment typically produce grating that is more durable and reliable.

3. Material Sourcing High-grade raw materials are crucial for producing quality I-bar grating. Factories with strong relationships with reputable suppliers are more likely to use high-quality steel or aluminum, which directly impacts the performance of the final product.

4. Customization Options The ability to provide customized solutions tailored to specific needs sets top factories apart. Whether it’s custom sizes, finishes, or load ratings, flexibility in production can help meet diverse client requirements.

best i bar grating factories

5. Sustainability Practices Many leading factories are increasingly focusing on sustainable manufacturing processes. This includes reducing waste and utilizing recyclable materials, ensuring that their production not only meets current demands but is also environmentally responsible.

Notable I-Bar Grating Factories

1. Walker Industrial Based in the United States, Walker Industrial has earned a reputation for high-quality I-bar grating. Their commitment to innovative production methods and stringent quality control has positioned them as industry leaders.

2. Bishop Lifting Products Also located in the U.S., Bishop specializes in custom I-bar grating solutions for various industries, including oil and gas. Their ability to provide personalized designs and robust testing protocols ensures optimal performance.

3. Grating Pacific This manufacturer not only focuses on I-bar grating but also provides a range of other grating solutions. They have a strong commitment to quality, with an extensive inventory allowing for quick turnarounds on custom orders.

4. Metalex Operating in Canada, Metalex is known for its precision-engineered I-bar grating products. Their innovative approach to manufacturing, combined with rigorous quality assessments, ensures reliable and durable grating solutions.

5. Ironwood Ironwood is an Australian manufacturer renowned for its commitment to environmentally sustainable manufacturing. They provide a range of I-bar grating products while ensuring their processes are eco-friendly, appealing to clients who prioritize sustainability.

Conclusion

In summary, when it comes to sourcing high-quality I-bar grating, the choice of factory can significantly impact the performance and durability of the product. Factories that leverage advanced manufacturing techniques, prioritize quality control, and offer customization will likely stand out in this competitive market. As industries continue to evolve, the demand for superior I-bar grating will expand, making it essential for factories to adapt and innovate to maintain their edge. Whether you’re in construction, manufacturing, or any industry that requires robust and reliable grating solutions, partnering with the right factory is critical to achieving operational success.

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Heat Retention,Versatile Cooking

NewsAug.16,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Heat Retention&Non-Stick Surface

NewsAug.16,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Heat Retention, Non-Stick, Multi-Functional

NewsAug.16,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Heat Retention,Non-Stick Surface

NewsAug.16,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Heat Retention&Non-Stick Surface

NewsAug.15,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Heat Retention, Versatile Design

NewsAug.15,2025