Nov . 15, 2024 18:27 Back to list

best plaster expanded metal mesh manufacturer

The Best Plaster Expanded Metal Mesh Manufacturer A Comprehensive Overview

When it comes to construction materials, expanded metal mesh has gained significant recognition for its versatility and functionality. Particularly in plaster applications, this mesh proves to be an invaluable asset, providing structural support and enhancing the durability of plaster installations. However, to achieve the best results, it is vital to source this material from a reputable manufacturer. In this article, we will delve into the qualities of the best plaster expanded metal mesh manufacturer and why it matters for your projects.

Understanding Expanded Metal Mesh

Expanded metal mesh is formed by cutting and stretching a flat sheet of metal, creating a pattern of diamond-shaped openings. This unique design offers numerous benefits, including increased strength, lightweight characteristics, and excellent airflow. When it comes to plastering, expanded metal mesh serves as a bonding interface, ensuring that the plaster adheres effectively to surfaces, reducing the risk of cracking or detachment.

Key Qualities of a Leading Manufacturer

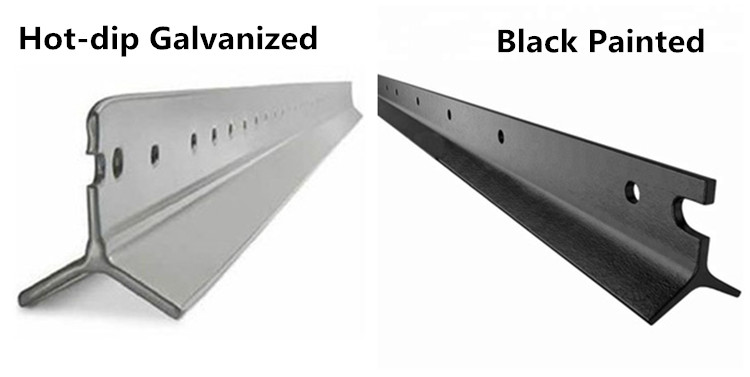

1. Material Quality The best manufacturers utilize high-grade materials, such as galvanized steel or stainless steel, which are treated to resist corrosion and wear. This enhances the longevity of the mesh, making it a wise investment for any construction project.

2. Innovative Manufacturing Processes Superior manufacturers adopt state-of-the-art manufacturing techniques. This not only guarantees precision in the mesh's dimensions and patterns but also allows for better customization based on the specific needs of clients. Automation, combined with skilled craftsmanship, leads to consistently high-quality products.

3. Variety of Options The top expanded metal mesh manufacturers offer a wide range of mesh types, including variations in thickness, sizing, and different metal grades. This variety enables customers to select the optimal mesh suited for their plastering applications, whether it’s for interior or exterior use.

4. Technical Support and Expertise A reliable manufacturer often provides technical support, offering guidance on mesh selection and installation. Their expertise can significantly aid contractors and builders in making informed decisions, ensuring the best performance from the mesh.

best plaster expanded metal mesh manufacturer

5. Sustainability Practices As environmental concerns grow, many leading manufacturers are adopting sustainable practices. They may use recycled materials, implement energy-efficient manufacturing processes, and produce meshes that contribute to energy efficiency in construction projects. Choosing a manufacturer committed to sustainability can enhance your project's overall ecological footprint.

6. Exceptional Customer Service The best manufacturers pride themselves on their customer service. They maintain clear communication throughout the purchasing process, ensuring that clients receive timely updates and assistance. A manufacturer that values its customers is likely to prioritize quality and reliability in their products.

7. Competitive Pricing While quality often comes at a premium, a top-tier manufacturer offers competitive pricing without compromising on the material’s integrity. This balance between affordability and quality is crucial for contractors working within budget constraints.

Why Choosing the Right Manufacturer Matters

Selecting the right expanded metal mesh manufacturer is critical to the success of any plastering project. Quality materials lead to durable structures, minimizing maintenance costs in the long run. Poor-quality mesh can result in failures, such as cracks or even complete detachment of plaster finishes, leading to costly repairs and project delays.

Moreover, partnering with a reputable manufacturer often means gaining access to additional resources, including technical support and after-sales service, all of which can greatly enhance project efficiency and success.

Conclusion

In conclusion, when seeking the best plaster expanded metal mesh manufacturer, it is essential to consider multiple factors, including material quality, manufacturing processes, and customer support. This choice impacts not just the immediate outcome of your projects but also their long-term viability. By selecting a manufacturer committed to excellence, you can rest assured that your plaster applications will stand the test of time, providing both aesthetic beauty and structural integrity to your constructions.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025