Welcome to our websites!

Feb . 17, 2025 13:09 Back to list

Chain link wire mesh fence

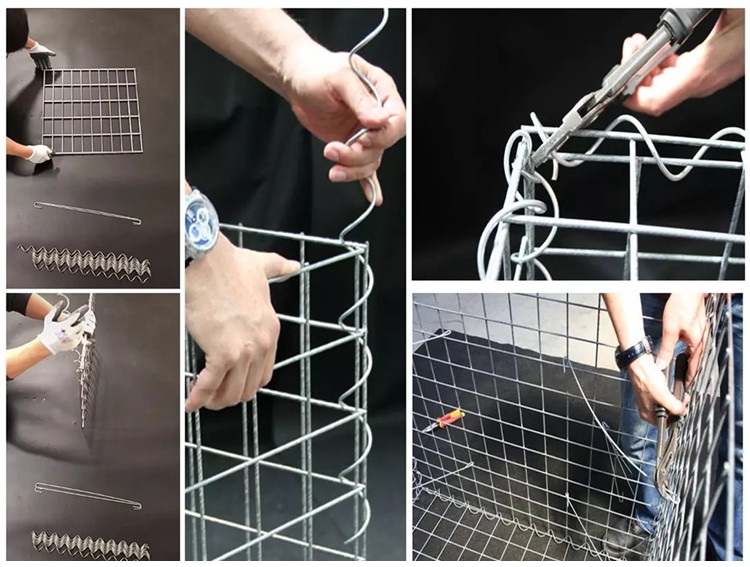

Gabions, a critical element in modern construction and landscaping, have become increasingly popular in China due to their versatility, durability, and cost-effectiveness. These wire mesh containers filled with stone or other materials serve multiple purposes, from retaining walls to embankment stabilization. Understanding the cost structure of gabions in China requires a thorough examination of various factors that influence their pricing and value.

Sustainability aspects are increasingly significant in assessing the overall value of gabions. Products made from recycled materials or those with a low carbon footprint align with global ecological trends. Chinese manufacturers have keenly embraced these practices, offering recycled steel mesh options that meet ecologically conscious buyers' demands while often reducing costs. One cannot ignore the impact of scale economies on gabion pricing. Large projects or bulk orders benefit from discounts due to optimized production and negotiation leverage with suppliers. Additionally, purchasing directly from a manufacturer versus through intermediaries can substantially lower the cost. The expertise of Chinese manufacturers in the gabion market further bolsters their cost competitiveness. With decades of experience and a strong domestic market, producers have honed their skills, ensuring reliable product quality and innovative solutions. This expertise is crucial for clients seeking customized gabion applications, whether for aesthetic purposes in landscapes or strategic functions in civil engineering projects. Trustworthiness remains a crucial consideration when engaging with suppliers. Reputable Chinese manufacturers provide clear, detailed quotes, adhere to promised delivery schedules, and maintain high customer service standards. Their commitment to transparency reassures buyers of receiving value proportionate to cost. In summary, the cost of gabions in China is a multifaceted evaluation encompassing material quality, production efficiencies, logistical variables, and supplier reliability. Industry buyers looking to leverage China's manufacturing advantages should approach suppliers who prioritize quality, sustainability, and service excellence, ensuring that their investment yields substantial functional and economic returns.

Sustainability aspects are increasingly significant in assessing the overall value of gabions. Products made from recycled materials or those with a low carbon footprint align with global ecological trends. Chinese manufacturers have keenly embraced these practices, offering recycled steel mesh options that meet ecologically conscious buyers' demands while often reducing costs. One cannot ignore the impact of scale economies on gabion pricing. Large projects or bulk orders benefit from discounts due to optimized production and negotiation leverage with suppliers. Additionally, purchasing directly from a manufacturer versus through intermediaries can substantially lower the cost. The expertise of Chinese manufacturers in the gabion market further bolsters their cost competitiveness. With decades of experience and a strong domestic market, producers have honed their skills, ensuring reliable product quality and innovative solutions. This expertise is crucial for clients seeking customized gabion applications, whether for aesthetic purposes in landscapes or strategic functions in civil engineering projects. Trustworthiness remains a crucial consideration when engaging with suppliers. Reputable Chinese manufacturers provide clear, detailed quotes, adhere to promised delivery schedules, and maintain high customer service standards. Their commitment to transparency reassures buyers of receiving value proportionate to cost. In summary, the cost of gabions in China is a multifaceted evaluation encompassing material quality, production efficiencies, logistical variables, and supplier reliability. Industry buyers looking to leverage China's manufacturing advantages should approach suppliers who prioritize quality, sustainability, and service excellence, ensuring that their investment yields substantial functional and economic returns.

Share

Latest news

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025