Nov . 21, 2024 19:00 Back to list

china scaffold board

The Importance of Scaffold Boards in Construction An Overview

Scaffold boards are essential components in the construction industry, providing crucial support and safety for workers at elevated heights. These boards are primarily used to create platforms for workers, equipment, and materials, ensuring that construction projects run smoothly and safely. This article will explore the significance of scaffold boards, their materials, safety standards, and best practices for using them effectively.

What Are Scaffold Boards?

Scaffold boards are typically made of wood or metal, and they serve as flat surfaces placed horizontally on scaffolding frames. Wooden scaffold boards are often made from high-quality timber, while metal boards may be constructed from steel or aluminum. The choice between wood and metal depends on various factors, including the type of project, weight capacity requirements, and environmental considerations.

Materials Used in Scaffold Boards

Wooden scaffold boards are known for their versatility and ease of use. Commonly used types of wood include Scandinavian pine or European spruce, chosen for their strength, durability, and resistance to splintering. These boards undergo treatment to resist decay and insect damage, making them ideal for outdoor use on construction sites.

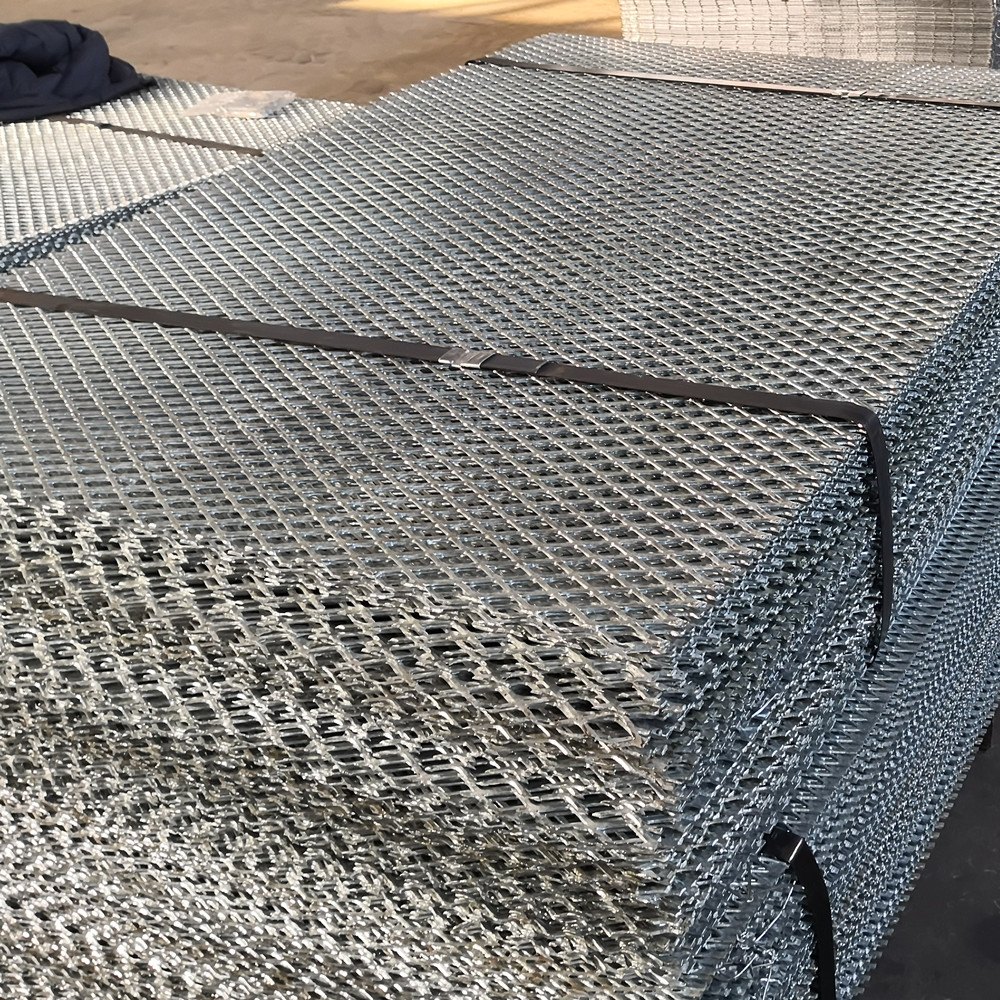

On the other hand, metal scaffold boards, often made of steel or aluminum, offer enhanced strength and a longer lifespan compared to their wooden counterparts. They are particularly beneficial in industrial applications where heavy loads are common, as they can bear greater weight without compromising safety. Additionally, metal boards typically have a non-slip surface, which enhances worker safety on high-altitude platforms.

Safety Standards and Regulations

Safety is paramount in construction, particularly when working at heights. Scaffold boards must comply with specific safety standards to ensure the protection of workers. In many countries, scaffold boards must adhere to regulations set out by occupational health and safety administrations. For instance, in the United States, the Occupational Safety and Health Administration (OSHA) has detailed guidelines regarding the use and maintenance of scaffold systems.

china scaffold board

These regulations include requirements for the proper inspection, load capacity, and maintenance of scaffold boards. Regular inspections ensure that any wear and tear, such as splits, cracks, or decay in wooden boards, or corrosion in metal boards, is addressed promptly. By ensuring compliance with these safety guidelines, construction companies can reduce the risk of accidents and enhance workplace safety.

Best Practices for Using Scaffold Boards

1. Regular Inspections Before each use, scaffold boards should be thoroughly inspected for any damage or wear. This practice helps prevent accidents caused by equipment failure.

2. Proper Weight Distribution It's crucial to adhere to the load capacity limits of scaffold boards to ensure safe use. Overloading can lead to structural failure and serious injuries.

3. Training Workers should receive training on the proper use of scaffold systems, including the correct way to set up and dismantle scaffolding.

4. Non-Slip Measures If using wooden scaffold boards, consider applying a non-slip finish to minimize the risk of slips and falls, especially in wet conditions.

5. Storage and Maintenance Scaffold boards should be stored in a dry area to prevent rot in wooden boards. Metal boards should be cleaned regularly to prevent corrosion.

Conclusion

In conclusion, scaffold boards are a vital part of the scaffolding system in the construction industry. Their role in providing a safe working platform at heights cannot be overstated. By selecting the right materials, adhering to safety standards, and following best practices, construction professionals can ensure a safer working environment and contribute to the overall success of construction projects. Prioritizing safety and quality in scaffold board usage ultimately safeguards the well-being of workers and the successful completion of construction tasks.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025