Welcome to our websites!

Jan . 20, 2025 04:36 Back to list

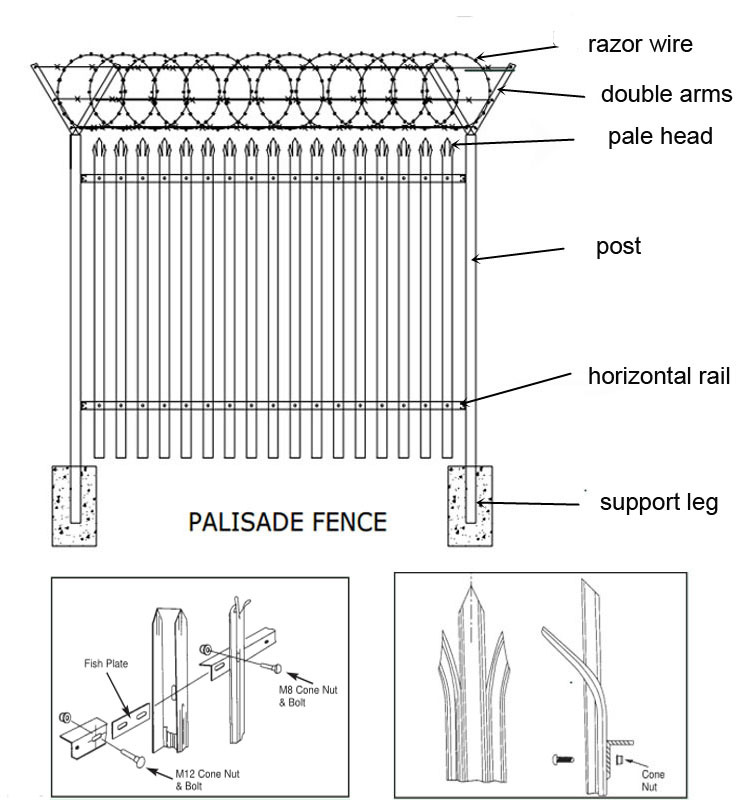

Hot-dip Galvanized Flat Wrap Razor Wire (Ring Type)

Maximizing Security with Coil Razor Wire An Expert’s Guide

Despite its efficacy in preventing unauthorized access, coil razor wire can pose safety challenges. Compliance with local legislation and standards is crucial to prevent liabilities. Safety gear must be worn during installation to prevent injuries. Moreover, appropriate signage around the perimeter serves as a warning, deterring potential intruders while informing the public. Coil Razor Wire Maintenance An Ongoing Commitment Regular maintenance is necessary to sustain the wire's efficacy. Inspecting for damage, rust, or corrosion, especially after adverse weather, is vital. By doing so, any signs of weakening can be addressed promptly, ensuring continuous protection. Furthermore, lubricating the wire occasionally can extend its lifespan while maintaining its intimidating sheen. Trust and Reliability Choosing the Right Supplier To maximize coil razor wire's effectiveness, partnering with reputable suppliers is key. They bring not only the product but also expertise and support. Reading user reviews, checking for industry certifications, and asking for technical support options are part of the vetting process. A reliable supplier provides a comprehensive warranty, installation guidance, and after-sales service, reinforcing trust. Real-World Applications and Success Stories Various entities such as military bases, correctional facilities, and private corporations cite notable security enhancements after installing coil razor wire. Successful deployments often combine coil razor wire with advanced technological integrations like surveillance systems, which synergize to form an impenetrable barrier. A pertinent case involved a logistics company suffering losses due to theft. After installing coil razor wire on their perimeter fence, not only did the theft incidents drop significantly, but the perceived sense of security amongst employees enhanced workplace morale. Conclusion The strategic use of coil razor wire can transform a vulnerable area into a formidable fortress. Its installation signifies a proactive approach to security, safeguarding assets and ensuring peace of mind. Industry experts continuously advocate for innovation and adherence to best practices to harness coil razor wire’s full potential. By integrating such solutions, organizations worldwide affirm their commitment to security, making coil razor wire not just a choice but a necessity in comprehensive security strategies.

Despite its efficacy in preventing unauthorized access, coil razor wire can pose safety challenges. Compliance with local legislation and standards is crucial to prevent liabilities. Safety gear must be worn during installation to prevent injuries. Moreover, appropriate signage around the perimeter serves as a warning, deterring potential intruders while informing the public. Coil Razor Wire Maintenance An Ongoing Commitment Regular maintenance is necessary to sustain the wire's efficacy. Inspecting for damage, rust, or corrosion, especially after adverse weather, is vital. By doing so, any signs of weakening can be addressed promptly, ensuring continuous protection. Furthermore, lubricating the wire occasionally can extend its lifespan while maintaining its intimidating sheen. Trust and Reliability Choosing the Right Supplier To maximize coil razor wire's effectiveness, partnering with reputable suppliers is key. They bring not only the product but also expertise and support. Reading user reviews, checking for industry certifications, and asking for technical support options are part of the vetting process. A reliable supplier provides a comprehensive warranty, installation guidance, and after-sales service, reinforcing trust. Real-World Applications and Success Stories Various entities such as military bases, correctional facilities, and private corporations cite notable security enhancements after installing coil razor wire. Successful deployments often combine coil razor wire with advanced technological integrations like surveillance systems, which synergize to form an impenetrable barrier. A pertinent case involved a logistics company suffering losses due to theft. After installing coil razor wire on their perimeter fence, not only did the theft incidents drop significantly, but the perceived sense of security amongst employees enhanced workplace morale. Conclusion The strategic use of coil razor wire can transform a vulnerable area into a formidable fortress. Its installation signifies a proactive approach to security, safeguarding assets and ensuring peace of mind. Industry experts continuously advocate for innovation and adherence to best practices to harness coil razor wire’s full potential. By integrating such solutions, organizations worldwide affirm their commitment to security, making coil razor wire not just a choice but a necessity in comprehensive security strategies.

Share

Latest news

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025

-

Galvanized Iron Wire Anti Mosquito Window Screen Net | Durable

NewsAug.03,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing Solutions&Customizable Construction Site Security

NewsAug.02,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

NewsAug.02,2025