Dec . 10, 2024 16:01 Back to list

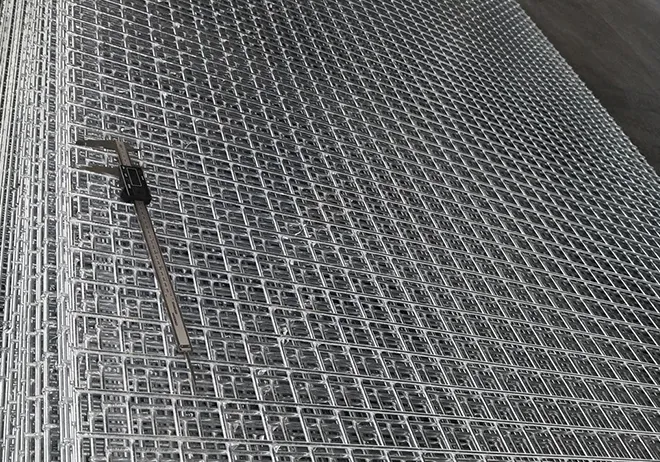

expanded mesh roll product

Understanding Expanded Mesh Roll Products

Expanded mesh roll products are versatile materials created through the process of stretching and cutting sheets of metal or other materials into a mesh design. This manufacturing technique involves the careful manipulation of a material into a network of openings, creating a lightweight yet sturdy product that boasts a wide array of applications across various industries.

The Manufacturing Process

The production of expanded mesh begins with a solid sheet of material, typically metals such as aluminum, stainless steel, or mild steel. The sheet is then fed into a machine that uses a combination of cutting and stretching to create the characteristic diamond-shaped openings. This process not only increases the surface area of the material but also enhances its strength and rigidity. The final product is a roll of expanded metal mesh which offers flexibility in handling and transportation.

Expanded mesh rolls can be produced in different thicknesses and sizes depending on the intended use. The expansion ratio can also vary, which determines the size of the openings and the overall appearance of the mesh. When the expanded metal sheet is rolled up, it becomes easier to transport and store, making it an efficient product for manufacturers and builders alike.

Versatility and Applications

Expanded mesh rolls are recognized for their versatility in numerous applications. One of the key sectors utilizing this product is the construction industry. Expanded mesh is often employed as reinforcement material in concrete and plaster, adding strength and durability to structures. It is also used in fencing, offering a lightweight yet secure barrier for properties, gardens, and commercial spaces.

In architecture, expanded metal is used for façades, providing an attractive design element while allowing airflow and light to permeate a building. This not only enhances aesthetic appeal but also improves energy efficiency. Furthermore, the mesh can be customized with coatings or finishes to match specific design requirements or environmental needs.

In the industrial sector, expanded mesh rolls are invaluable for creating safety barriers, grates, and platforms. The high strength-to-weight ratio makes it ideal for a variety of equipment and machinery applications. Additionally, its non-combustible nature makes it suitable for areas requiring fire-resistant materials.

expanded mesh roll product

Advantages Over Other Mesh Types

Compared to woven or welded mesh products, expanded mesh offers several advantages. Its one-piece construction means that it does not have any joints or welds, which can be potential points of failure under stress. The uninterrupted material enhances strength and creates a more durable product that is less likely to fray or unravel over time.

Moreover, the design of expanded mesh allows for airflow and drainage, making it ideal for applications where moisture management is critical. For example, in landscaping and gardening, expanded mesh can be laid over soil to prevent erosion while still allowing water to flow through.

Customization and Finishing

Another appealing aspect of expanded mesh roll products is their ability to be customized. Manufacturers can offer a range of finishes, including galvanization, painting, or powder coating, which not only improves aesthetic qualities but also adds protective layers to prevent rust and corrosion. This customization extends to the sizing of the roll itself, with options available to suit specific project requirements.

Architects and designers appreciate the wide range of patterns and sizes that can be achieved with expanded mesh. This adaptability allows them to create innovative and functional designs that can effectively meet user needs while also upholding aesthetic standards.

Conclusion

In summary, expanded mesh roll products represent a crucial component in many industries, demonstrating significant versatility and strength. From the construction sector to architectural applications, the lightweight yet durable nature of this material has solidified its status as a preferred choice among engineers, architects, and builders. As technology continues to evolve, the potential applications for expanded mesh will only expand, offering new solutions to longstanding challenges in various fields. Whether you're looking to reinforce a structure or enhance the design of a building, expanded mesh rolls provide an innovative and effective option to consider.

-

358 Anti Climb Welded Wire Mesh Fence - Secure Perimeter Defense

NewsAug.02,2025

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025