Jul . 28, 2024 08:50 Back to list

Exploring the Cost Options for High-Quality Bar Grating Products in the Market Today

Understanding the Pricing of Bar Grating Products

Bar grating is a versatile and essential component used in various applications, including industrial flooring, drainage covers, walkways, and more. Constructed from high-quality materials such as steel, aluminum, or fiberglass, bar grating offers strength, durability, and safety. The pricing of bar grating products is influenced by several factors, which we will explore in this article.

Material Composition

The type of material used is one of the primary factors affecting the price of bar grating. Steel grating is often more affordable than aluminum or fiberglass due to the lower material costs. However, aluminum provides a lightweight alternative that is resistant to corrosion, making it more suitable for outdoor applications or environments where moisture is prevalent. Fiberglass grating, while generally the most expensive, offers exceptional resistance to chemicals and is often used in specialized industrial settings. Buyers must consider the specific application requirements alongside budget constraints when selecting the appropriate material.

Manufacturing Process

The manufacturing process also plays a critical role in determining the price of bar grating. Products that require custom fabrication, such as specific sizes or load-bearing specifications, tend to be pricier than standard options. Custom bar grating often involves intricate cutting, welding, or finishing processes, which can significantly increase labor costs. Bulk orders may help to mitigate these costs as manufacturers often provide discounts for larger purchases.

Load Capacity and Design

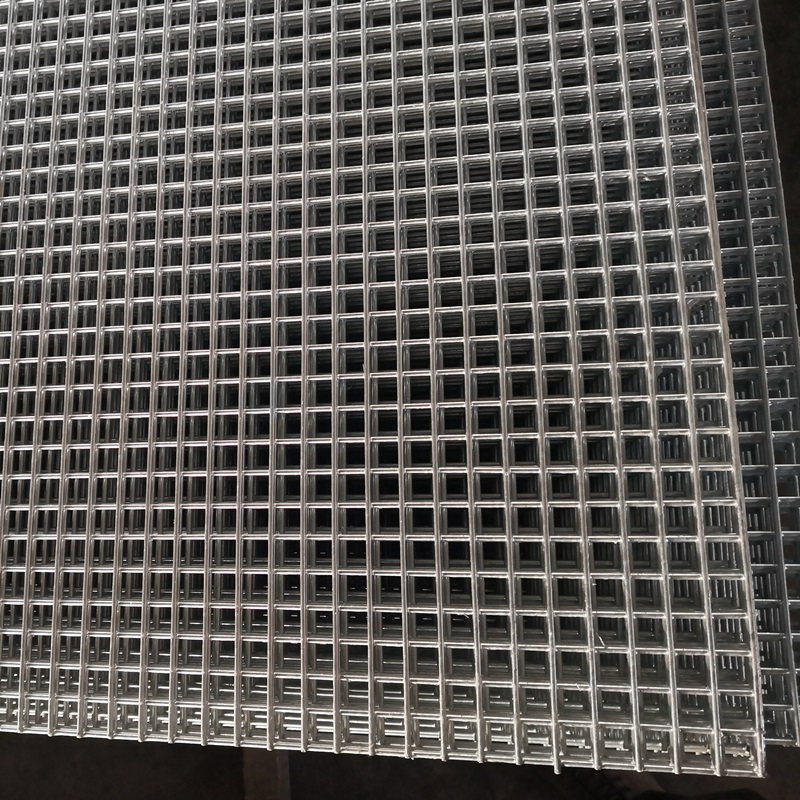

bar grating price product

Bar grating comes in various designs, including welded, swaged, and press-locked options, each with different load capacities. The load-bearing requirements dictate not only the design choice but also the thickness of the bars and spacing between them. Heavier-duty grating, which is designed to support larger weights, naturally comes at a higher price point. Buyers need to assess their load requirements carefully to avoid overspending on unnecessary capacity or, conversely, risking safety by under-specifying.

Coatings and Treatments

To enhance corrosion resistance and increase the longevity of bar grating, coatings and treatments are often applied. Galvanization, powder coating, and painting are common methods used to protect steel bar grating from environmental factors. Each of these treatments adds to the overall cost of the product, but they can be seen as an investment in reducing long-term maintenance and replacement expenses. Buyers should weigh the initial cost against the potential savings on upkeep when considering coated versus uncoated options.

Market Demand and Economic Factors

Like all products, the pricing of bar grating can be influenced by market demand and broader economic conditions. Increased industrial activity often leads to higher demand for construction materials, which can drive prices up. Additionally, fluctuations in raw material prices, labor costs, and transportation fees due to inflation or supply chain disruptions can also impact the final pricing of bar grating.

Conclusion

Understanding the various factors influencing the price of bar grating products is crucial for making informed purchasing decisions. By considering material type, manufacturing processes, load specifications, protective coatings, and market conditions, buyers can select the most suitable bar grating that meets their needs and budget. Investing time in thorough research can lead to long-term savings and improved safety in various applications, ensuring that the right product is chosen for the right job.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025