Dec . 23, 2024 19:37 Back to list

famous welded wire mesh price

Understanding the Prices of Welded Wire Mesh What You Need to Know

Welded wire mesh has emerged as a popular choice for various applications, ranging from construction to agricultural uses. Its durability and strength make it ideal for reinforcing concrete, creating enclosures, and safeguarding areas against intruders or pests. However, one of the first questions that arise when considering welded wire mesh is what influences its price? In this article, we'll explore the factors affecting the price of welded wire mesh and provide insights to help you make informed purchasing decisions.

Composition and Manufacturing Process

The price of welded wire mesh is primarily influenced by its composition and the manufacturing process. The most common material used for welded wire mesh is low carbon steel, but there are other options available, such as stainless steel and galvanized wire. Each material offers different advantages in terms of corrosion resistance and strength, and the choice of material can significantly affect the overall cost. For example, stainless steel welded wire mesh will generally be more expensive than its low carbon counterpart due to its enhanced durability and resistance to rust.

The manufacturing process also plays a crucial role in pricing. High-quality welded wire mesh undergoes a meticulous process where individual wires are welded together at each junction, ensuring structural integrity. Less expensive alternatives may compromise on the quality of welding, leading to weaker grids. Therefore, when comparing prices, it’s essential to consider whether you are looking at similar quality and standards.

Mesh Size and Wire Gauge

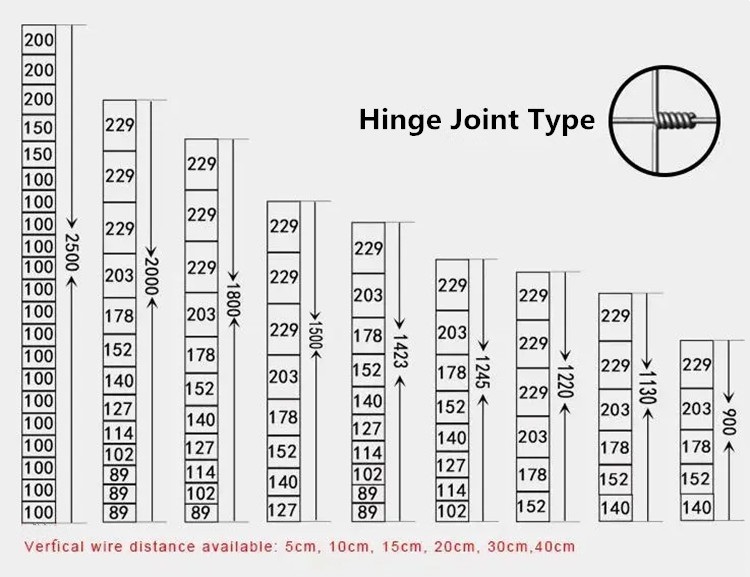

Another factor impacting the cost is the size of the mesh and the gauge of the wire used. Welded wire mesh is available in various mesh sizes (the distance between the wires) and wire gauges (the thickness of the wire). Generally, finer mesh sizes and thicker wire gauges are more expensive due to the increased material usage and the requirements for more precise manufacturing processes. In projects where strength and security are paramount, investing in heavier-duty mesh can be worthwhile, even if it comes at a higher price point.

famous welded wire mesh price

Market Demand and Supply Chain Factors

Market dynamics also play a significant role in determining welded wire mesh prices. Economic conditions, demand for construction materials, and fluctuations in raw material costs can lead to price variations. For instance, during peak construction seasons or in response to supply chain disruptions, prices may surge due to high demand and limited availability. Conversely, in periods of low construction activity, prices might stabilize or even decrease.

Additional Considerations

When evaluating the price of welded wire mesh, consider any additional costs that may arise. Transportation and shipping fees, especially for large orders, can significantly impact your overall expenditure. It’s essential to factor in these additional costs when budgeting for a large-scale project.

Furthermore, the source from which you purchase the welded wire mesh can also influence the pricing. Local manufacturers might offer competitive prices due to reduced shipping costs, but sometimes imported products may be cheaper. Always research multiple suppliers to ensure you find the best price without compromising on quality.

Conclusion

In summary, the price of welded wire mesh is influenced by various factors, including material composition, manufacturing processes, mesh size, wire gauge, and market dynamics. By understanding these factors, you will be better equipped to make informed decisions that best suit your project needs. Whether you are using welded wire mesh for construction, agricultural fencing, or other applications, being mindful of pricing factors can lead to significant savings and higher quality in your purchases. Always compare different suppliers and consider the long-term benefits of investing in quality materials.

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025