Welcome to our websites!

Jan . 14, 2025 11:04 Back to list

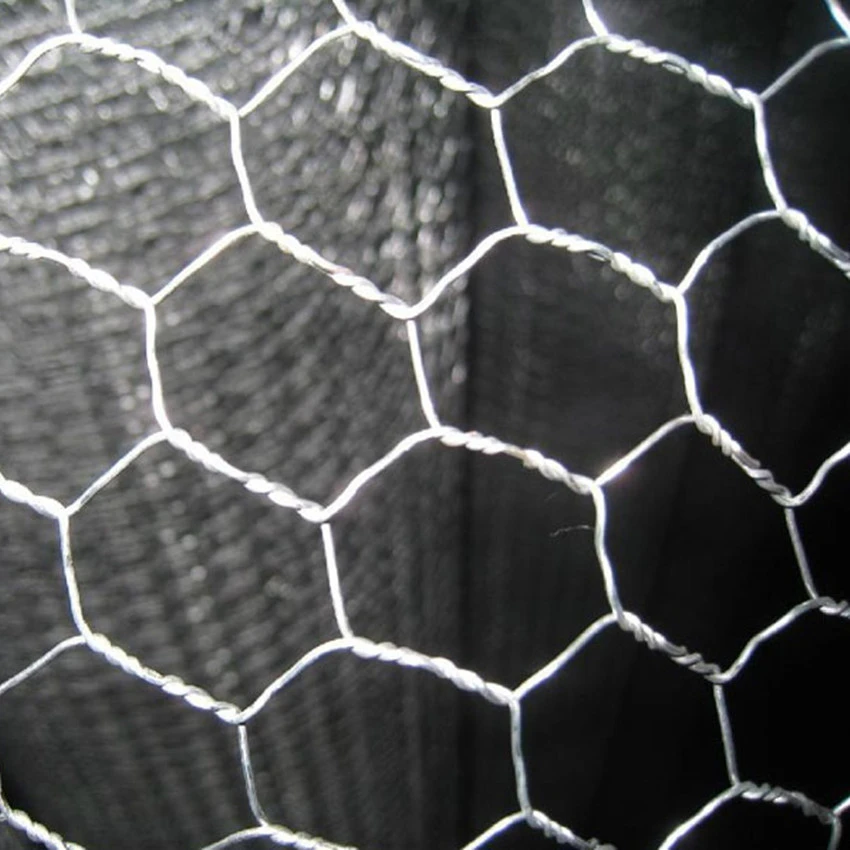

Fiberglass insect screen / Mosquito window mesh

Welded mesh is a pioneering solution for numerous construction and industrial applications, driven by its robustness, versatility, and ease of use. This product transcends basic functionality, becoming a vital component in modern engineering and construction practices. This article explores the various facets of welded mesh, drawing from real-world applications and expert insights to enhance your understanding and application of this indispensable material.

Trustworthiness in welded mesh is underlined by stringent testing and compliance with international standards. Both manufacturers and suppliers undergo rigorous assessments to ensure the mesh's safety and performance. Certifications by recognized bodies are not merely formalities but essential markers of a reliable product. Experienced professionals in the industry recommend checking for these credentials to gauge the quality and suitability of the mesh for specific projects. A seasoned construction manager might recount instances where substituting traditional reinforcement methods with welded mesh significantly reduced costs and installation times. This real experience is echoed by many in the field, lauding its ease of installation as it comes in ready-to-use panels that require minimal adjustment on site. This saves labor, reduces waste, and speeds up project timelines. In conclusion, welded mesh is more than just a reinforcement tool; it is an epitome of superior engineering and reliability. Its applications have evolved across industries, proving indispensable for both practical and innovative solutions. The product's development is backed by technical expertise, compliance with authoritative standards, and the trust forged through successful real-world applications. As you incorporate welded mesh into your projects, you leverage a legacy of proven performance and future-oriented engineering.

Trustworthiness in welded mesh is underlined by stringent testing and compliance with international standards. Both manufacturers and suppliers undergo rigorous assessments to ensure the mesh's safety and performance. Certifications by recognized bodies are not merely formalities but essential markers of a reliable product. Experienced professionals in the industry recommend checking for these credentials to gauge the quality and suitability of the mesh for specific projects. A seasoned construction manager might recount instances where substituting traditional reinforcement methods with welded mesh significantly reduced costs and installation times. This real experience is echoed by many in the field, lauding its ease of installation as it comes in ready-to-use panels that require minimal adjustment on site. This saves labor, reduces waste, and speeds up project timelines. In conclusion, welded mesh is more than just a reinforcement tool; it is an epitome of superior engineering and reliability. Its applications have evolved across industries, proving indispensable for both practical and innovative solutions. The product's development is backed by technical expertise, compliance with authoritative standards, and the trust forged through successful real-world applications. As you incorporate welded mesh into your projects, you leverage a legacy of proven performance and future-oriented engineering.

Share

Latest news

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing&Versatile Installation

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Construction&Versatile Applications

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd

NewsAug.05,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable, Modular, Corrosion Resistant

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Surface Treatments&Versatile Applications

NewsAug.05,2025

-

Steel Expanded Metal Mesh Fence: Secure & Durable Perimeter Solution

NewsAug.05,2025