Dec . 11, 2024 09:53 Back to list

Galvanized Chicken Wire Production and Manufacturing Insights for Quality and Durability

The Importance and Versatility of Galvanized Chicken Wire An Overview of Factories and Production

In the realm of fencing and agricultural supplies, galvanized chicken wire holds a prominent position due to its adaptability and resilience. This seemingly simple product plays a critical role in various applications, from poultry farming to gardening and construction. This article delves into the significance of galvanized chicken wire, exploring the factories that produce it, the manufacturing process, and its numerous uses.

Understanding Galvanized Chicken Wire

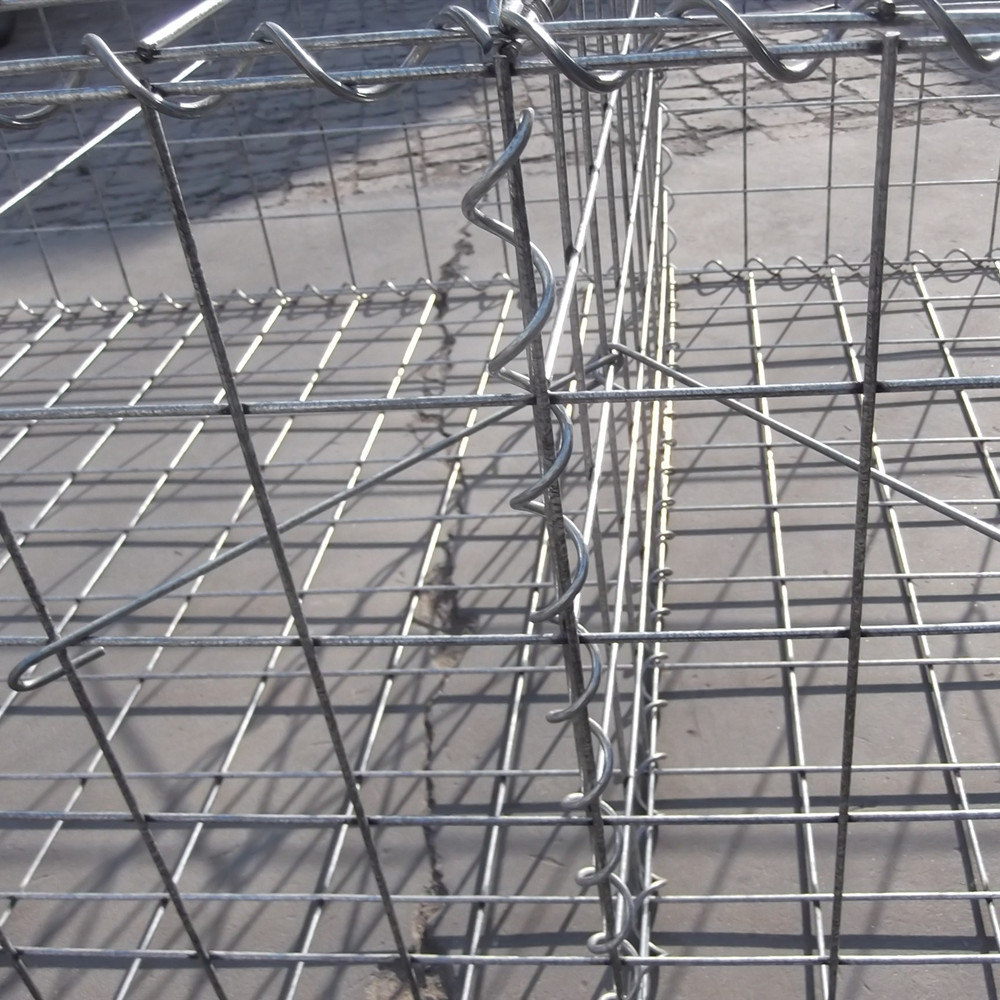

Galvanized chicken wire, also known as poultry netting or wire mesh, is made from iron or steel wire that has been coated with a layer of zinc to prevent rusting. This galvanization process enhances the wire's durability and longevity, making it ideal for both indoor and outdoor applications. The mesh is typically characterized by its hexagonal shape, which provides a sturdy barrier while allowing air and light to penetrate.

The Manufacturing Process

The production of galvanized chicken wire is a meticulous process, beginning with the selection of high-quality raw materials. Factories start by sourcing the finest steel or iron wire, which is then drawn into the desired thickness. Following this, the wire is twisted into the hexagonal mesh shape.

Once the wire is shaped, it undergoes the galvanization process, which can be achieved through two primary methods hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing involves dipping the wire into molten zinc, forming a thick, protective layer that is highly resistant to rust. In contrast, electro-galvanizing applies a thinner zinc coating through an electrolytic process. The choice between these methods often depends on the intended use of the wire; hot-dip is preferred for outdoor applications due to its superior corrosion resistance.

Factories and Their Role

galvanized chicken wire factories

The production of galvanized chicken wire is typically carried out in specialized factories equipped with advanced machinery. These facilities often employ skilled workers who ensure that each step of the production process meets strict quality standards. Many factories also engage in continuous research and development to innovate and improve their products, adapting to the evolving needs of consumers.

In addition to producing galvanized chicken wire, many factories offer customization options. This can include variations in mesh size, wire gauge, and roll length, catering to specific requirements for different applications. Furthermore, some manufacturers focus on sustainable practices, utilizing recycled materials and eco-friendly processes to minimize their environmental impact.

Applications of Galvanized Chicken Wire

The versatility of galvanized chicken wire is one of its most appealing attributes. It is widely used in poultry farming, providing a secure and safe environment for birds. Farmers utilize the wire to construct coops, fencing, and runs, ensuring that their livestock is protected from predators while allowing for adequate ventilation and light.

Beyond agriculture, galvanized chicken wire finds applications in gardening and landscaping. Gardeners use it to create protective barriers around plants, preventing damage from pests and animals. Additionally, it serves as a support structure for climbing plants and can even be fashioned into unique garden art or trellises.

Moreover, galvanized chicken wire is prominent in construction and home improvement projects. Builders and DIY enthusiasts often employ it for safety fencing, compost bins, and reinforcing concrete. Its durability and ease of installation make it a preferred choice for various construction applications.

Conclusion

Galvanized chicken wire is an essential product within numerous industries, from agriculture to construction. The factories that produce it play a vital role in ensuring its quality and availability. With versatile applications and robust construction, galvanized chicken wire continues to be a trusted choice for securing livestock, protecting gardens, and enhancing construction projects. As consumer needs evolve, the industry is likely to see further innovations in galvanized wire products, solidifying its place as a staple in both rural and urban settings. The future holds promise for this enduring material, making it a key player in sustainable farming and construction practices.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025