Dec . 01, 2024 00:20 Back to list

galvanized expanded metal mesh factories

Galvanized Expanded Metal Mesh Factories A Comprehensive Overview

Galvanized expanded metal mesh, a versatile and durable material, has become an essential component in numerous industries. This unique product is created by taking a flat sheet of metal, usually steel or aluminum, and expanding it through a process of slitting and stretching. The result is a mesh-like structure that combines strength with lightweight properties. To maintain its integrity and longevity, the mesh is often galvanized, which involves coating it with a layer of zinc to prevent rust and corrosion.

The Importance of Galvanization

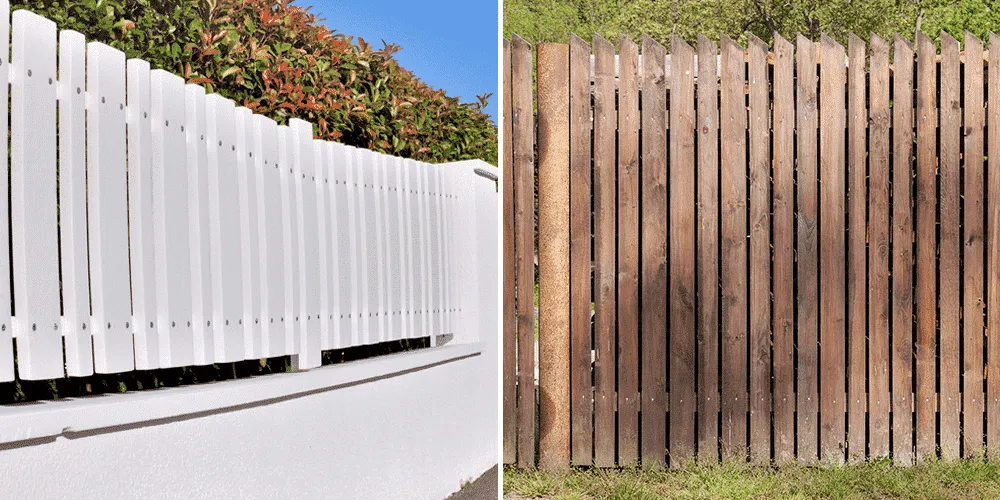

The galvanization process significantly enhances the longevity of expanded metal mesh. Without this protective layer, metal is susceptible to oxidation and exposure to various environmental elements, which can lead to deterioration over time. Galvanized expanded metal mesh is particularly popular in outdoor applications where durability is a concern, such as in construction, fencing, architectural features, and even in the manufacturing of various equipment.

Manufacturing Process in Factories

The manufacturing of galvanized expanded metal mesh takes place in specialized factories equipped with advanced machinery. The process generally involves several key steps

1. Material Selection Factories typically begin by selecting high-quality sheets of metal. Steel is the most common material due to its strength, but aluminum is also used when lightweight properties are crucial.

2. Expansion The selected sheets are then processed through a series of machines that slit and stretch the metal, creating the uniform openings characteristic of expanded mesh. This process not only enhances the strength-to-weight ratio but also provides a surface that is ideal for applications ranging from flooring to security enclosures.

3. Galvanization After the mesh has been created, it is galvanized. This is often done through hot-dip galvanization, where steel mesh is submerged in molten zinc. This method ensures comprehensive coverage and adhesion, significantly extending the mesh's lifespan.

galvanized expanded metal mesh factories

4. Quality Control Factories enforce strict quality control measures throughout the manufacturing process. Inspections are conducted to ensure that the mesh meets industry standards concerning size, strength, and coating thickness. This step is vital to maintaining the integrity of the finished product.

5. Customization Many manufacturers offer customization options, allowing clients to order expanded metal mesh in various thicknesses, patterns, and dimensions suited to specific applications.

Applications of Galvanized Expanded Metal Mesh

The applications of galvanized expanded metal mesh are vast and varied. In the construction industry, it serves as a reinforcement material in concrete and as protective barriers in architectural designs. In the industrial sector, it is utilized for grating, walkways, and protective coverings in machinery. The agricultural sector also employs this material for fencing and ventilation solutions in livestock housing.

The Future of Galvanized Expanded Metal Mesh

As industries continue to evolve, the demand for galvanized expanded metal mesh is expected to grow. Innovations in manufacturing techniques and materials are likely to enhance the versatility and performance of this product even further. Sustainability trends may also lead to the increased use of recycled metals in the production process, aligning with global efforts to reduce waste and promote eco-friendly practices.

Conclusion

In conclusion, galvanized expanded metal mesh factories play a crucial role in producing this essential material that serves multiple industries. With its durability, versatility, and protective characteristics, galvanized expanded metal mesh continues to be a preferred choice for builders, manufacturers, and architects alike. As technology advances and environmental concerns shape production practices, the future of galvanized expanded metal mesh appears bright, promising continued growth and innovation in its applications.

-

358 Anti Climb Welded Wire Mesh Fence - Secure Perimeter Defense

NewsAug.02,2025

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025