Dec . 03, 2024 16:50 Back to list

galvanized gabion mesh box factory

Understanding Galvanized Gabion Mesh Box Factories

As the construction and landscaping industries continue to evolve, the demand for effective and sustainable solutions is on the rise. Among the most versatile and robust options available today are galvanized gabion mesh boxes. These structures are not only ideal for erosion control and soil stabilization but also serve aesthetic purposes in landscape design. In this article, we will delve into the manufacturing process, advantages, and applications of galvanized gabion mesh boxes and explore the role of factories dedicated to producing these essential components.

What Are Gabion Mesh Boxes?

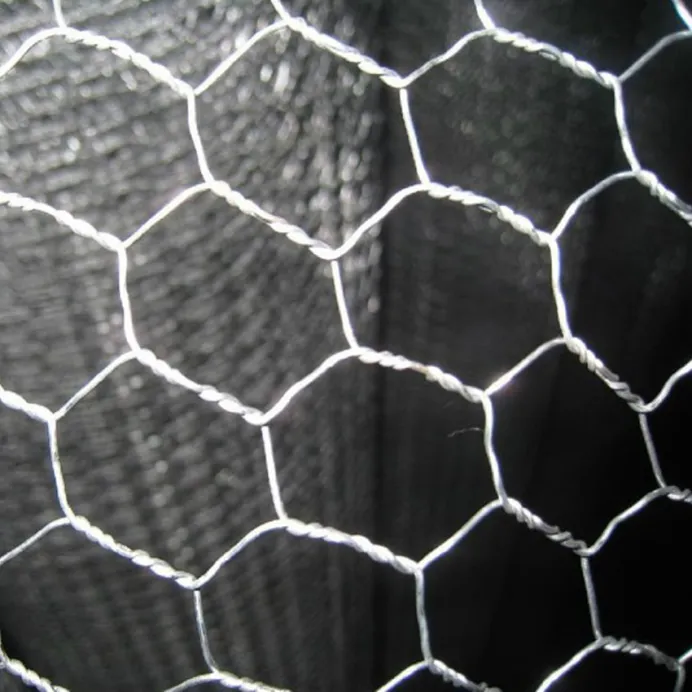

Gabion mesh boxes are wire mesh containers, usually filled with rock, concrete, or other materials, that are used to create sturdy walls, barriers, and decorative features in various environments. The term gabion originates from the Italian word gabbione, meaning big cage. These boxes can effectively mitigate erosion, control flooding, and enhance the visual appeal of outdoor spaces. What sets galvanized gabion mesh boxes apart is their enhanced durability, achieved through a layer of zinc coating that protects the wire from rust and corrosion.

The Manufacturing Process

The production of galvanized gabion mesh boxes involves several steps, all of which take place in specialized factories designed for this purpose.

1. Wire Production The first step is the creation of high-quality steel wire. Factories typically start with raw steel, which is drawn down to create wires of varying gauges. The choice of wire gauge affects the strength and flexibility of the gabion boxes.

2. Galvanization After wire production, the next crucial process is galvanization. This involves coating the wire with a layer of zinc, which prevents corrosion and extends the life of the gabion. This process can be done using hot-dip galvanization or electro-galvanization methods, with hot-dip generally providing a thicker and more durable coating.

3. Mesh Formation Once galvanized, the wires are woven or welded into a mesh format. This mesh must meet specific criteria regarding its size and strength to ensure it can withstand the weight and pressure from the materials it will contain.

galvanized gabion mesh box factory

4. Box Assembly After the mesh is formed, the individual pieces are cut and assembled into gabion boxes of varying sizes. Factories may offer custom sizes based on client specifications, ensuring flexibility for different projects.

5. Quality Control The final step in the manufacturing process is rigorous quality control. Each gabion box is tested for structural integrity and compliance with industry standards to ensure they can perform as intended once deployed in the field.

Advantages of Galvanized Gabion Mesh Boxes

The popularity of galvanized gabion mesh boxes can be attributed to numerous advantages

- Durability The galvanized coating significantly enhances the longevity of the mesh, making it suitable for various environmental conditions, including wetlands and coastal areas. - Versatility Gabion boxes can be used in numerous applications, including retaining walls, slope stabilization, riverbank protection, and decorative landscaping. - Cost-effective Compared to traditional building materials, gabion boxes are often more economical, especially when the local stone or material can be utilized for filling. - Environmentally Friendly Gabion structures are made from natural materials, making them an eco-friendly option compared to concrete or asphalt.

Applications in Construction and Landscaping

Galvanized gabion mesh boxes are employed across various sectors. In construction, they are used for retaining walls and foundations, where they provide structural support while allowing for drainage. In landscaping, they serve as decorative elements, creating seating areas, garden walls, or paths that blend seamlessly into the environment. Moreover, gabions are beneficial in soil erosion control, acting as barriers that slow down water flow and prevent soil displacement.

Conclusion

Galvanized gabion mesh box factories play a pivotal role in providing a sustainable and versatile solution for modern construction and landscaping challenges. With durability, cost-effectiveness, and environmental benefits, galvanized gabions stand out as a robust choice in today's evolving architectural landscape. As the demand for innovative building solutions continues to grow, the importance of these factories in producing high-quality gabion boxes cannot be overstated, ultimately contributing to the development of resilient structures and beautiful landscapes worldwide.

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025

-

Galvanized Iron Wire Anti Mosquito Window Screen Net | Durable

NewsAug.03,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing Solutions&Customizable Construction Site Security

NewsAug.02,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

NewsAug.02,2025