Oct . 07, 2024 08:42 Back to list

galvanized welded mesh fence manufacturers

Understanding Galvanized Welded Mesh Fence Manufacturers

In the realm of fencing materials, galvanized welded mesh fences have gained significant attention for their durability, versatility, and aesthetic appeal. Manufacturers specializing in this type of fencing play a crucial role in providing solutions for various applications, from industrial areas to residential properties. In this article, we will explore the characteristics of galvanized welded mesh fences, the manufacturing process, and what to look for when selecting a manufacturer.

What is Galvanized Welded Mesh Fencing?

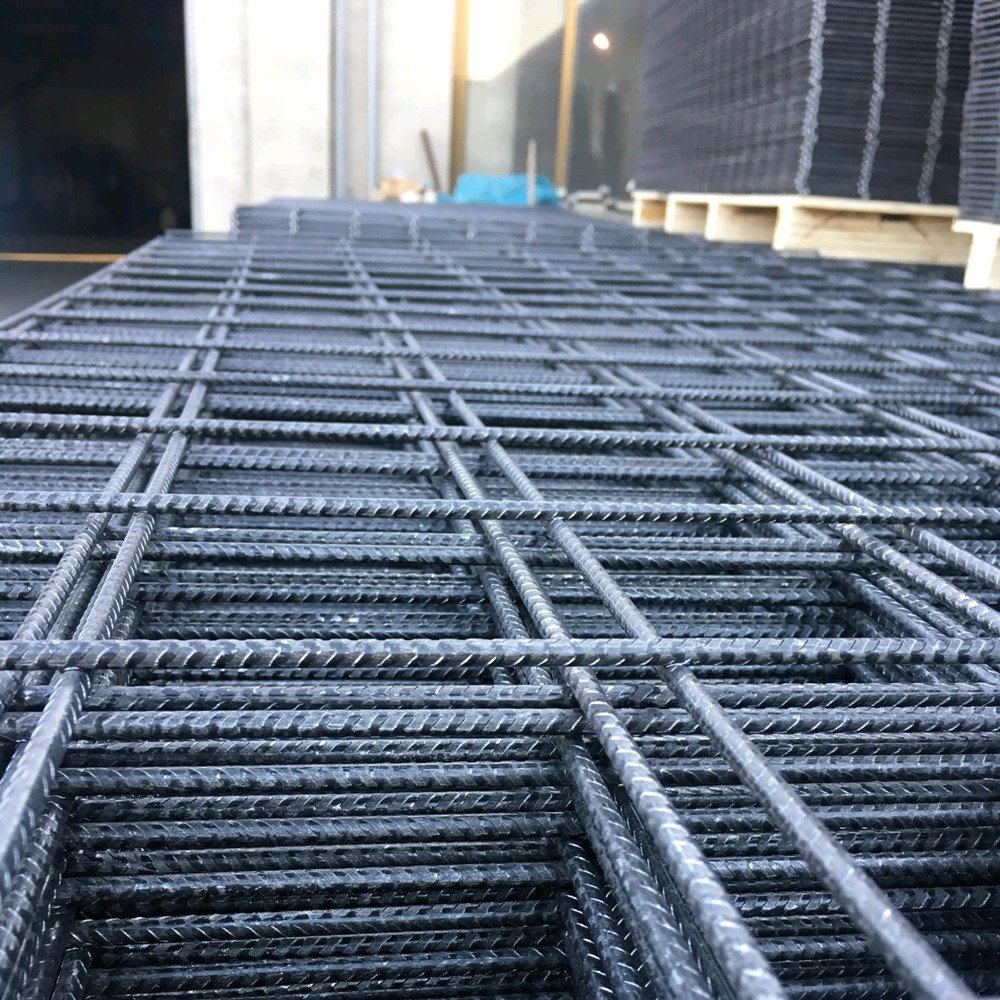

Galvanized welded mesh fencing is constructed from steel wires that are welded together to form a grid. The key feature of this fencing system is the galvanization process, which involves coating the steel with a layer of zinc to prevent rust and corrosion. This makes the fencing highly resilient against weather conditions and extends its lifespan significantly compared to non-galvanized counterparts.

Due to its design, galvanized welded mesh fences offer excellent visibility while providing security. This makes them an ideal choice for various settings, including residential yards, parks, commercial properties, and agricultural lands. They can also be customized to meet specific height and mesh size requirements, accommodating different security levels and aesthetic preferences.

The Manufacturing Process

The manufacturing of galvanized welded mesh fencing involves several steps

1. Wire Production The process begins with the production of high-quality steel wires. These wires are drawn to the desired thickness and can vary in gauge depending on the specific requirements.

2. Welding The welded mesh is produced by arranging the wires in a grid pattern. The intersections are then welded together using high-precision machinery. This creates strong joints that enhance the overall strength of the mesh.

3. Galvanization After welding, the mesh is subjected to the galvanization process, typically through hot-dip galvanization. This involves immersing the welded mesh in molten zinc to create a thick and durable coating that provides excellent resistance to corrosion.

galvanized welded mesh fence manufacturers

4. Quality Control Reputable manufacturers conduct rigorous quality control tests at various stages of production to ensure that the fencing meets industry standards. This includes checking for strength, durability, and coating quality.

5. Customization Many manufacturers offer customization services, allowing clients to define specific requirements such as mesh size, height, and finishing options.

Choosing the Right Manufacturer

When searching for galvanized welded mesh fence manufacturers, consider the following factors

1. Experience and Reputation Look for manufacturers with a proven track record and positive reviews. Experienced manufacturers are more likely to deliver high-quality products.

2. Quality Assurance Ensure that the manufacturer has stringent quality control processes in place. Certificates and industry standards compliance are indicators of reliability.

3. Customization Options Depending on your needs, it may be beneficial to partner with a manufacturer that offers customization options, enabling you to tailor the fencing to your specifications.

4. Customer Service Good customer service is crucial for addressing any inquiries or issues that may arise during the ordering process. A responsive manufacturer can enhance your overall experience.

5. Pricing and Value While price is an important consideration, it should not be the sole factor. Assess the value of the product in relation to its quality and longevity.

In conclusion, galvanized welded mesh fences are a sturdy and visually appealing choice for various fencing needs. By selecting a reputable manufacturer, you can ensure that you are investing in a quality product that will serve its purpose effectively for years to come. Whether for security or aesthetic reasons, these fences remain a practical solution in today’s market.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025