Dec . 17, 2024 20:55 Back to list

high quality serrated bar grating

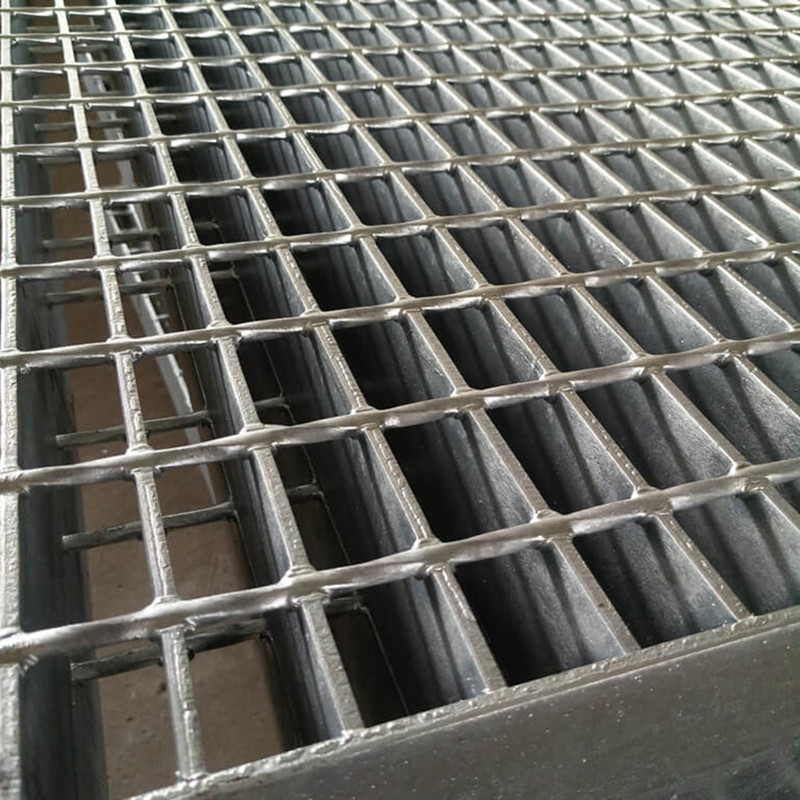

High-Quality Serrated Bar Grating An Overview

Serrated bar grating is an increasingly popular choice for a variety of applications due to its unique design and functionality. Constructed from high-quality materials, this type of grating features a series of parallel bars with a serrated edge, providing superior traction, durability, and safety in various environments. Whether used in industrial settings, commercial areas, or architectural applications, serrated bar grating offers numerous advantages that make it a preferred choice among engineers and designers.

Understanding Serrated Bar Grating

Serrated bar grating is typically made from steel, aluminum, or fiberglass, and consists of load-bearing bars arranged in a specific pattern. The serrations or indentations along the edges of the bars enhance slip resistance, making them ideal for environments where water, oil, or other potentially slippery substances might be present. This feature is particularly important in manufacturing facilities, chemical plants, and food processing environments, where safety is paramount.

Advantages of High-Quality Serrated Bar Grating

1. Enhanced Traction The serrated design significantly increases the grip underfoot, which is crucial in preventing slips and falls. This trait can be vital in workplaces that deal with heavy machinery or operate in hazardous conditions.

2. Weight and Load Distribution High-quality serrated bar grating provides excellent load-bearing capacity while remaining lightweight. This not only facilitates easy installation but also ensures that the structure can support significant weights, making it suitable for a wide range of applications, from walkways to heavy machinery.

3. Corrosion Resistance Many manufacturers treat their serrated bar gratings with anti-corrosive coatings or constructs them from materials that are inherently resistant to rust and degradation. This durability means a longer lifespan, even in harsh environmental conditions, reducing the need for frequent replacements.

high quality serrated bar grating

4. Versatility Serrated bar grating can be used in diverse environments, including industrial plants, sewage treatment facilities, power stations, and even pedestrian walkways. Its adaptability to various settings is one of the reasons it remains a popular choice.

5. Aesthetic Appeal Beyond functionality, high-quality serrated bar grating can be designed to blend in with architectural elements. Available in various finishes and colors, it can contribute to the overall aesthetic of a building or facility while still providing the necessary safety features.

Applications and Uses

The use of serrated bar grating spans across multiple industries. In industrial settings, it is commonly utilized for flooring applications, platforms, and walkways where both safety and durability are critical. Furthermore, in commercial buildings, it can provide efficient drainage solutions or decorative features in outdoor spaces.

In addition, these gratings are often used in areas that require ventilation and light transmission, such as stair treads and trench covers, where visibility is essential. Their ability to withstand high foot traffic while maintaining integrity makes them a top choice for both industrial applications and public spaces.

Conclusion

Serrated bar grating is an exemplary solution for those seeking a combination of safety, durability, and aesthetic appeal. When constructed from high-quality materials, these gratings can provide excellent performance and longevity, addressing various needs across multiple industries effectively. Whether it’s for a new construction project, renovation, or safety upgrade, investing in high-quality serrated bar grating can lead to enhancements in both safety and functionality, ultimately contributing to a more efficient and secure environment.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025