Nov . 30, 2024 08:19 Back to list

Quality Hot Dip Galvanized Wire Mesh Manufacturer with Competitive Prices and Fast Delivery

The Importance of Hot Dip Galvanized Wire Mesh in Modern Construction

In the realm of construction and various industrial applications, the significance of quality materials cannot be overstated. One such vital material is hot dip galvanized wire mesh, which has gained widespread popularity due to its durability and corrosion resistance. This article delves into the various aspects of hot dip galvanized wire mesh, highlighting the processes involved in its production, its applications, and the advantages it offers when sourced from a reputable factory.

Understanding Hot Dip Galvanization

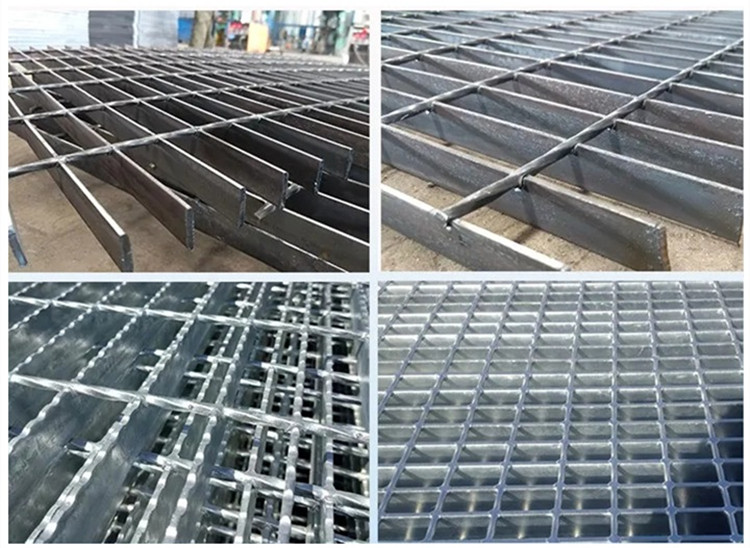

Hot dip galvanization is a process that involves coating steel or iron with a layer of zinc to protect it from corrosion. This method offers a more robust and longer-lasting solution compared to other galvanization techniques. The process includes cleaning the metal surface, dipping it into molten zinc, and allowing it to cool, forming a strong bond between the zinc and the metal. This results in a wire mesh that can withstand harsh environmental conditions, making it ideal for various applications.

Manufacturing Process of Hot Dip Galvanized Wire Mesh

A hot dip galvanized wire mesh factory employs advanced machinery and technology to produce high-quality products. The manufacturing process typically begins with the selection of raw materials, followed by wire drawing, where large coils of steel are drawn into thinner wires. The next step involves weaving these wires into various mesh patterns, depending on the desired specifications. Once the mesh fabric is created, it undergoes the hot dip galvanization process, which ensures that the entire mesh is uniformly coated in zinc.

Quality control is a crucial component of the manufacturing process. Factories implement rigorous testing and inspection protocols to ensure that the finished wire mesh meets international standards for strength, durability, and corrosion resistance. This meticulous attention to quality guarantees that customers receive products that can withstand the test of time.

Applications of Hot Dip Galvanized Wire Mesh

hot dip galvanized wire mesh factory

The versatility of hot dip galvanized wire mesh makes it suitable for a wide range of applications. In construction, it is commonly used for reinforcing concrete structures, providing added strength and stability. It is also employed in fencing, livestock enclosures, and garden applications where durability and resistance to weather elements are necessary.

Moreover, the wire mesh is utilized in industrial settings, serving as protective barriers and safety guards. Its corrosion-resistant properties make it especially useful in chemical plants, waste treatment facilities, and other environments where exposure to harsh substances is commonplace.

Advantages of Choosing a Reliable Factory

When it comes to purchasing hot dip galvanized wire mesh, sourcing from a reputable factory is paramount. Such factories often adhere to stringent quality control measures, ensuring that their products meet or exceed expectations. Additionally, they provide access to a range of customization options, allowing customers to select the mesh size, wire gauge, and coating thickness that best fits their project requirements.

A reliable factory also prioritizes customer service, offering support throughout the ordering process and beyond. This includes providing accurate timelines for production and delivery, as well as addressing any concerns or queries promptly. By opting for certified manufacturers, customers can rest assured that they are investing in high-quality materials that will contribute to the longevity and safety of their construction projects.

Conclusion

In conclusion, hot dip galvanized wire mesh is a crucial component in modern construction and industrial applications. Its superior resistance to corrosion and durability makes it an ideal choice for various uses. By choosing products from a reputable factory, customers can ensure they receive high-quality materials that will stand the test of time. As the demand for reliable and sustainable building materials continues to grow, hot dip galvanized wire mesh remains a key player in shaping the future of construction.

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025