Aug . 12, 2024 11:46 Back to list

Innovative Solutions for Enhanced Production in the Barbed Wire Manufacturing Industry

The Unsung Art of Barbed Wire Manufacturing

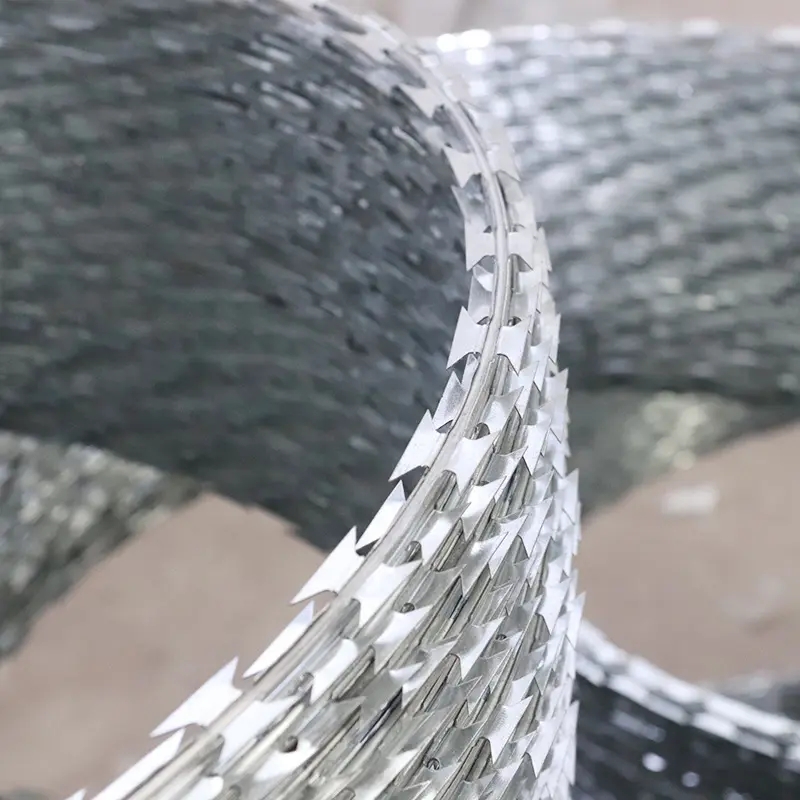

Barbed wire may seem like a simple and utilitarian product, but the process of its manufacturing is a fascinating blend of artistry and engineering. The barbed wire factory serves as a remarkable facility where raw materials are transformed into an essential element of modern fencing and security.

At its core, barbed wire consists of a twisted strand of wire adorned with sharp barbs. This design not only prevents the unwanted passage of animals and people but also evokes a sense of rustic charm. The history of barbed wire dates back to the late 19th century, when it revolutionized the way farmers and ranchers organized their land. Today, barbed wire is used worldwide, highlighting its versatility and importance across different sectors.

The journey of barbed wire begins with high-quality steel. Factories typically source robust steel wires, as the material must withstand tension and potential weathering. Once the steel wires arrive at the factory, they undergo a rigorous quality control process, ensuring only the best materials are used for production. This is critical, as any flaw in the wire can compromise the integrity of the final product.

The manufacturing process of barbed wire is quite intricate. Firstly, the steel wires are drawn through a series of dies to achieve the desired thickness. This drawing process strengthens the wires and prepares them for the next stages of production. Afterward, multiple strands are twisted together to create the main body of the wire. This twisting not only enhances strength but also allows for the attachment of barbs at regular intervals.

barbed wire factory

The creation of barbs, which are key to the wire's effectiveness, involves another specialized process. Small pieces of wire are often cut and shaped into sharp points that are then attached to the main wire strand. These barbs must ensure optimal spacing and strength, as they play a crucial role in deterring intruders while maintaining the fence's overall durability.

Once the barbed wire is formed, it undergoes additional treatments to enhance its resistance to corrosion and wear. Galvanization, where the wire is coated in zinc, is a common method employed in many factories. This coating protects the wire from harsh weather conditions and extends its lifespan significantly. Other factories may opt for alternative protective coatings to suit specific environmental conditions or customer needs.

Notably, the barbed wire factory is an epitome of skilled craftsmanship. Workers involved in the manufacturing process often possess a deep understanding of metallurgy and engineering principles, allowing them to produce high-quality products consistently. Over the years, advancements in technology have also played an essential role in improving production efficiency. Automated machinery is now commonly utilized, reducing the chances of human error and ensuring uniformity in the products.

Moreover, the barbed wire factory also reflects environmental consciousness. Many modern facilities focus on sustainability; they often employ measures to recycle materials and reduce waste. This commitment to eco-friendly practices ensures that the manufacturing process has a minimal impact on the environment.

In summary, the manufacturing of barbed wire is a complex yet fascinating process that combines traditional craftsmanship with modern technology. From sourcing steel to final production, every step is meticulously executed in a barbed wire factory. As an essential component in securing properties and livestock, barbed wire continues to play a vital role in our lives, often going unnoticed. The next time you encounter a barbed wire fence, take a moment to appreciate the intricate work that goes into creating this remarkable product.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025