Welcome to our websites!

Jan . 14, 2025 10:43 Back to list

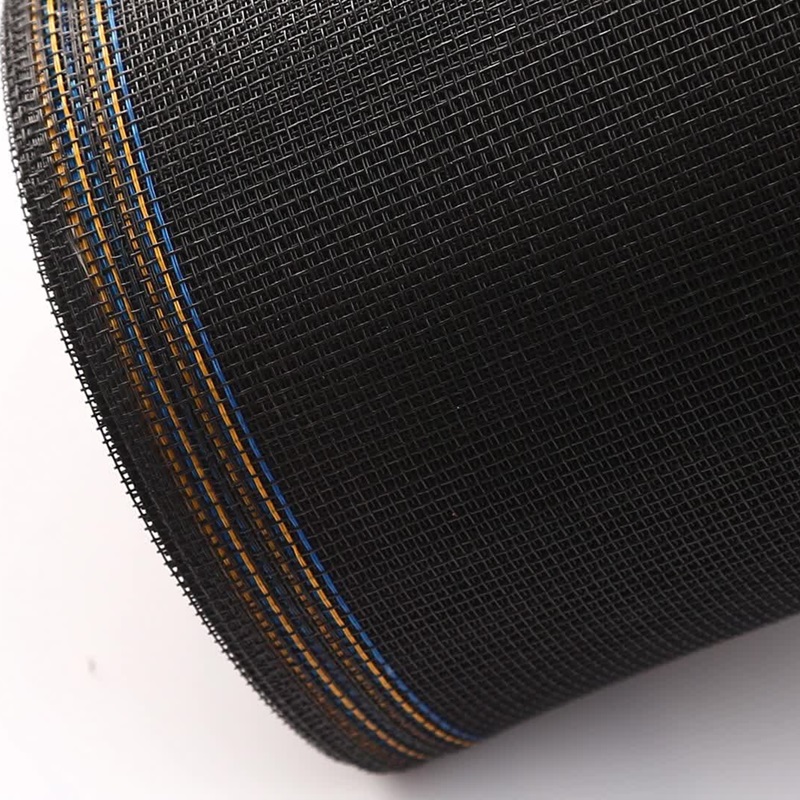

metal wire mesh

Metal wire mesh stands as an incredibly versatile product, integrating seamlessly into countless applications across industries. Rooted in centuries of practical use, it has continuously evolved, offering solutions for modern challenges in architecture, agriculture, construction, and beyond.

Moreover, the application of metal wire mesh in eco-friendly solutions cannot be overstated. Growing environmental consciousness has led to innovative applications such as green wall mesh systems, which support vertical gardens and contribute to energy efficiency in buildings. Similarly, the agriculture sector deploys wire mesh in sustainable fencing solutions, which withstands harsh conditions while providing a secure boundary for livestock. In terms of product range, the diversity available in metal wire mesh is staggering. From woven and welded options to expanded and perforated varieties, each type serves specific functions, dictated by the project’s demands. Fine mesh with tiny apertures is ideal for filtration and sieving, whereas larger grid patterns provide structural support without obstructing light or airflow. Lastly, leveraging technological advancements, some producers have integrated digital modeling and simulation tools into their processes. This advancement facilitates precise fabrication to meet intricate designs before committing material resources, ensuring cost efficiency, and reducing waste. Such innovations reflect the ongoing commitment within the industry to meld traditional craftsmanship with cutting-edge technology. Ultimately, the relevance of metal wire mesh continues to grow, with each application reinforcing its indispensability and reliability. As industries expand and evolve, so too does the ingenuity applied to this remarkable material, affirming its place in both current and future innovations.

Moreover, the application of metal wire mesh in eco-friendly solutions cannot be overstated. Growing environmental consciousness has led to innovative applications such as green wall mesh systems, which support vertical gardens and contribute to energy efficiency in buildings. Similarly, the agriculture sector deploys wire mesh in sustainable fencing solutions, which withstands harsh conditions while providing a secure boundary for livestock. In terms of product range, the diversity available in metal wire mesh is staggering. From woven and welded options to expanded and perforated varieties, each type serves specific functions, dictated by the project’s demands. Fine mesh with tiny apertures is ideal for filtration and sieving, whereas larger grid patterns provide structural support without obstructing light or airflow. Lastly, leveraging technological advancements, some producers have integrated digital modeling and simulation tools into their processes. This advancement facilitates precise fabrication to meet intricate designs before committing material resources, ensuring cost efficiency, and reducing waste. Such innovations reflect the ongoing commitment within the industry to meld traditional craftsmanship with cutting-edge technology. Ultimately, the relevance of metal wire mesh continues to grow, with each application reinforcing its indispensability and reliability. As industries expand and evolve, so too does the ingenuity applied to this remarkable material, affirming its place in both current and future innovations.

Share

Next:

Latest news

-

358 Anti Climb Welded Wire Mesh Fence - Secure Perimeter Defense

NewsAug.02,2025

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025