Oct . 02, 2024 22:10 Back to list

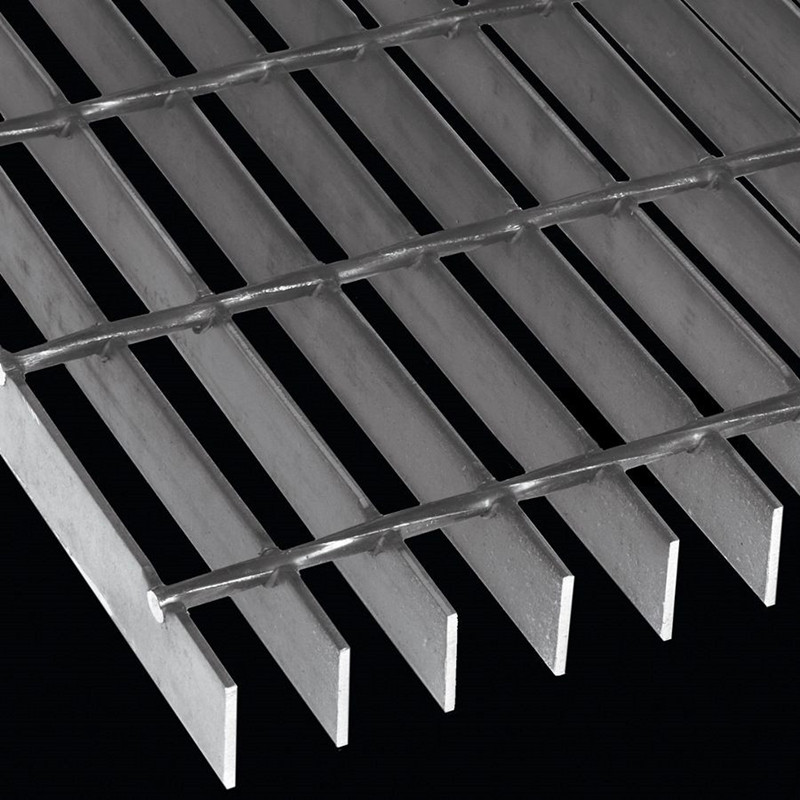

High-Quality Custom Galvanized Welded Wire Mesh for Various Applications

Understanding OEM Galvanized Welded Mesh Applications and Benefits

OEM (Original Equipment Manufacturer) galvanized welded mesh has become an essential component in various industries due to its versatile applications and unique properties. This article aims to explore the significance of galvanized welded mesh, its manufacturing process, and its numerous applications across different sectors.

Galvanized welded mesh is made from high-quality steel wire that is welded together to form a robust and durable structure. The term galvanized refers to the process of coating the wire with a layer of zinc. This zinc coating provides excellent corrosion resistance, which is crucial for applications that are exposed to moisture or harsh environmental conditions. The combination of welding and galvanization results in a mesh product that boasts high tensile strength, longevity, and reliable performance.

One of the main advantages of OEM galvanized welded mesh is its customization. OEM manufacturers can tailor the mesh specifications—including wire diameter, mesh size, and coating thickness—to meet the specific needs of various projects. This flexibility allows for the production of unique designs that can cater to specialized applications, thereby maximizing functionality and efficiency.

Applications of OEM Galvanized Welded Mesh

1. Construction Industry In the construction sector, galvanized welded mesh is commonly used for reinforcement in concrete structures. It provides essential support to slabs, walls, and foundations, helping to prevent cracking and enhancing structural integrity. Additionally, this type of mesh is employed in fencing applications to ensure security around construction sites.

oem galvanized welded mesh

2. Agriculture In agriculture, galvanized welded mesh is utilized for various purposes, including animal enclosures, crop protection, and fencing. The mesh allows for proper ventilation while keeping pests and larger animals out, making it ideal for both livestock and garden use.

3. Industrial Applications Many industries depend on galvanized welded mesh for storage and shelving solutions. It is commonly used in warehouses to create sturdy storage racks, helping businesses optimize their storage spaces efficiently. Moreover, this type of mesh is used in safety barriers, machinery guarding, and even as protective hardware for sensitive equipment.

4. Residential Uses Homeowners find galvanized welded mesh valuable for various applications, including garden fencing and trellises. Its aesthetic appeal combined with its durability makes it an excellent choice for enhancing the security and beauty of residential properties.

5. Transportation In the realm of transportation, galvanized welded mesh is utilized in the manufacturing of luggage racks and vehicle security. Its strength ensures that it can withstand the wear and tear of daily use, contributing to the safety and convenience of transporting goods.

Conclusion

In summary, OEM galvanized welded mesh represents a blend of strength, durability, and versatility. Its corrosion-resistant properties make it suitable for a myriad of applications across multiple industries, including construction, agriculture, and transportation. By partnering with OEM manufacturers, businesses can access customized solutions that cater to their specific requirements, ultimately enhancing productivity and efficiency. With the ongoing demand for reliable and durable materials in various sectors, galvanized welded mesh is likely to remain a staple choice for many years to come.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025