Oct . 06, 2024 22:05 Back to list

oem welded wire mesh

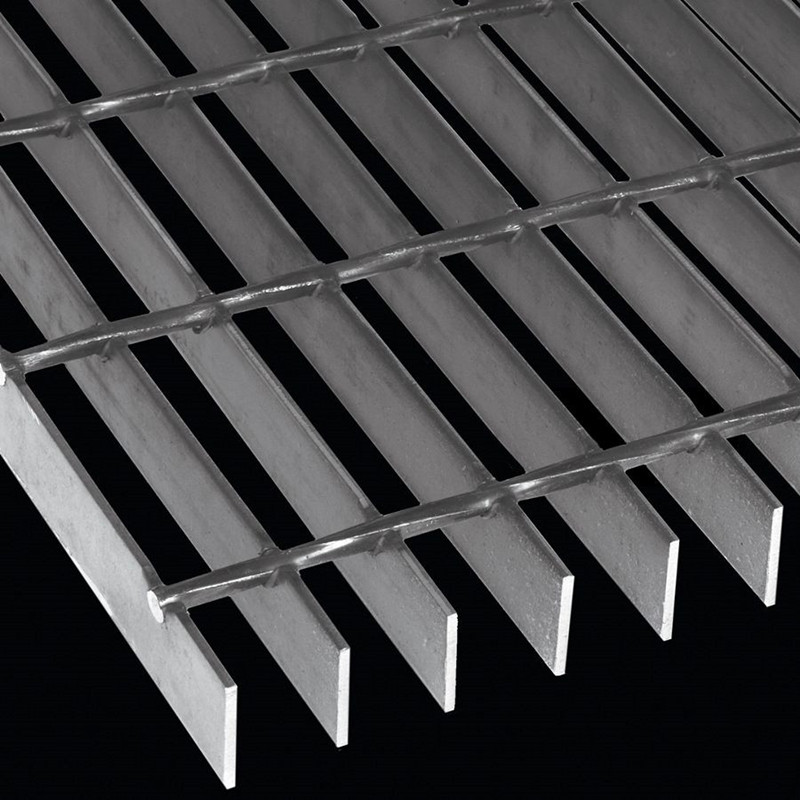

Exploring OEM Welded Wire Mesh Versatility and Applications

Welded wire mesh, often produced under Original Equipment Manufacturer (OEM) specifications, has become increasingly popular across various industries due to its versatility and durability. This type of mesh is created by welding intersecting wires, which ensures a high level of strength and stability, making it suitable for a multitude of applications.

Exploring OEM Welded Wire Mesh Versatility and Applications

In the construction industry, welded wire mesh is indispensable. It is widely used in concrete reinforcement, providing structural support and enhancing the tensile strength of concrete slabs, walls, and pavements. The robust nature of welded mesh helps prevent cracking and increases the longevity of construction projects. Moreover, it is also applied in creating safety barriers, fencing, and even temporary structures.

oem welded wire mesh

Agriculture is another sector where welded wire mesh plays a crucial role. Farmers utilize this mesh for fencing, crop protection, and livestock enclosures. Its sturdy design prevents pests from penetrating the protected areas while ensuring that livestock remain secure. Additionally, welded wire mesh can be used in greenhouses, providing essential support to climbing plants and improving overall crop yield.

The security sector also benefits significantly from OEM welded wire mesh products. High-security fencing made from welded wire mesh can deter intruders while offering visibility and airflow. It's particularly effective in protecting properties, schools, and industrial facilities. The mesh's resistance to cutting and bending increases security, making it a preferred choice for many organizations.

Furthermore, this product is environmentally friendly. Many manufacturers utilize recycled materials in the production process, which aligns with sustainable practices and reduces the carbon footprint associated with traditional fencing solutions.

In conclusion, OEM welded wire mesh presents a versatile solution for numerous applications across various industries. Its strength, durability, and customizability make it an essential component in construction, agriculture, and security. As industries continue to evolve, the demand for such adaptable materials will likely increase, highlighting the importance of innovative manufacturing practices in meeting future needs.

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing&Versatile Installation

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Construction&Versatile Applications

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd

NewsAug.05,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable, Modular, Corrosion Resistant

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Surface Treatments&Versatile Applications

NewsAug.05,2025

-

Steel Expanded Metal Mesh Fence: Secure & Durable Perimeter Solution

NewsAug.05,2025